In-Depth Analysis of High-Speed Metal Circular Sawing Machine

1.1. Market Demand for High-Efficiency Metal Processing

Modern manufacturing, particularly in critical sectors like aerospace, automotive, energy, and precision machinery, places stringent demands on metal raw material cutting. These requirements mainly focus on three areas:

- Ultimate Cutting Efficiency: To meet the needs of high-volume, high-cadence production and shorten the cycle time for component manufacturing.

- Exceptional Cutting Precision: To ensure the flatness, perpendicularity, and length tolerance of the cut workpiece end face meet the requirements of subsequent high-precision machining.

- Optimized Material Utilization: To reduce production costs through a narrower kerf and less waste.

Cutting equipment fulfilling these demands must possess characteristics of high rigidity, high automation, and high speed. It is against this industrial backdrop that the High-Speed Metal Circular Sawing Machine was developed.

1.2. Definition and Core Value of High-Speed Metal Circular Sawing Machine

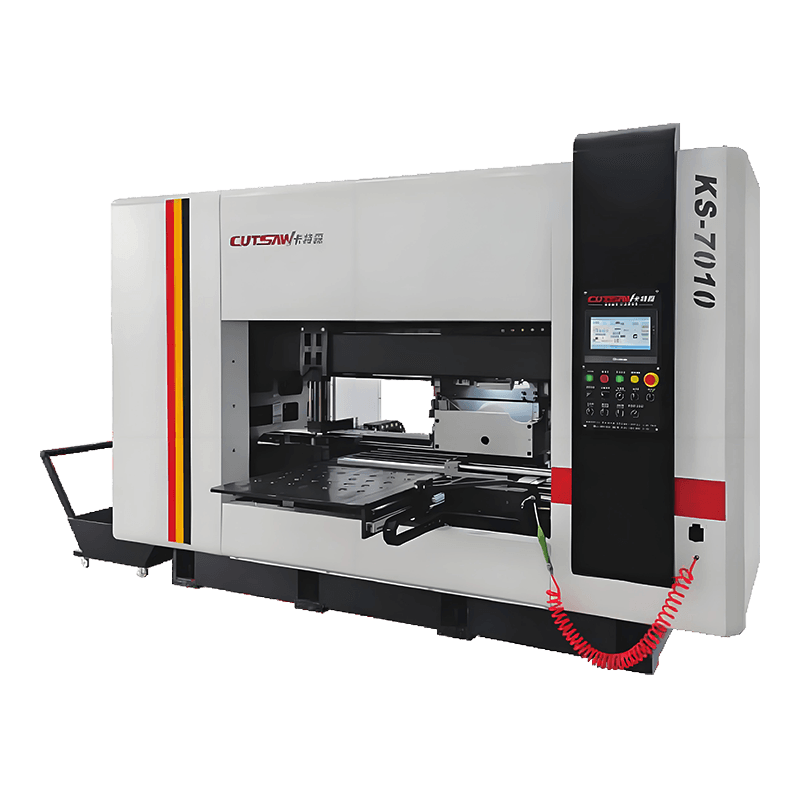

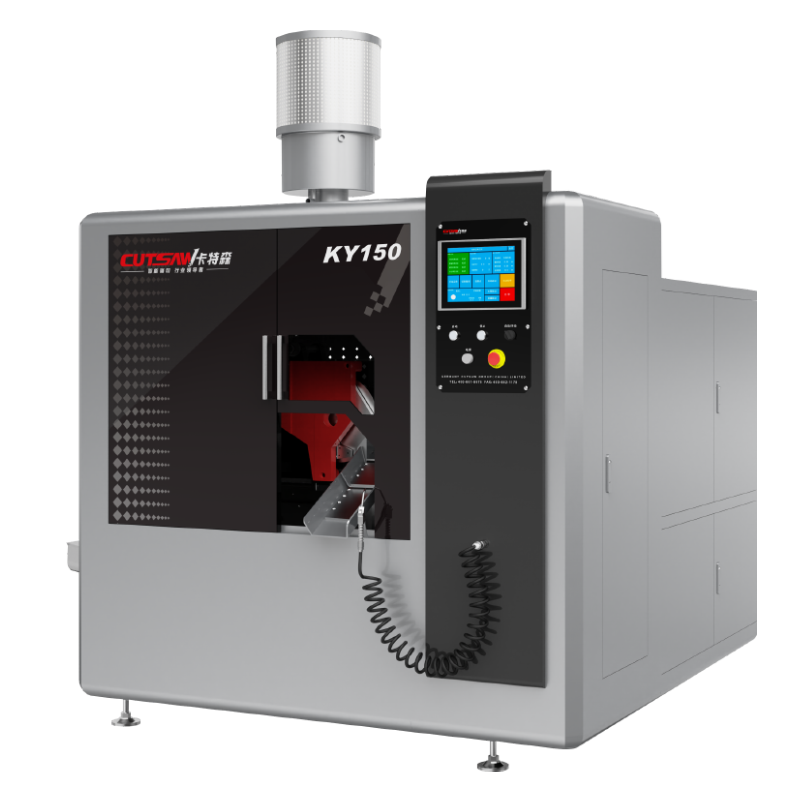

The High-Speed Metal Circular Sawing Machine is a highly automated machine designed specifically for high-speed, precise cutting of metal bar stock, tubes, and profiles. It utilizes circular saw blades made of special materials (such as Carbide TCT), coupled with a high-power spindle and a precise feeding system, to mill-cut the metal at extremely high peripheral speeds.

Its core value lies in:

| Core Value Dimension |

Contribution of High-Speed Metal Circular Sawing Machine |

| Increased Productivity |

Cutting speed far exceeds traditional sawing methods, leading to a significant increase in output per unit of time. |

| Optimized Cut Quality |

High surface finish on the cut face, requiring minimal or no subsequent finishing, shortening the process chain. |

| Stability and Reliability |

Meets the requirements for high-intensity, long-duration continuous production. |

Zhejiang Sinaida Machine Tools Co., Ltd., established on December 8, 2000, as a National High-tech Enterprise, deeply understands the importance of high-quality cutting technology. Located at No. 152 Xinggong Road, Huzhen Town Industrial Park, Jinyun County, Lishui City, Zhejiang Province, the company has secured ISO9001, China Machinery Safety Certification, and EU CE certification. Leveraging its excellent management and R&D team and strong technical capabilities, the company is dedicated to providing advanced CNC sawing equipment that meets industry requirements.

1.3. Comparative Advantages over Traditional Cutting Technologies

Compared to conventional cutting methods, the advantages of the High-Speed Metal Circular Sawing Machine manifest in efficiency, precision, and cost control.

| Comparison Feature |

High-Speed Metal Circular Sawing Machine |

Traditional Band Sawing Machine (Band Sawing Machine) |

Traditional Abrasive Sawing (Abrasive Sawing) |

| Cutting Speed (High-Speed) |

Extremely Fast (Milling principle, high feed rate) |

Slower (Reciprocating motion, limited feed rate) |

Relatively Fast, but limited by heat and consumables |

| Cutting Precision |

Extremely High (Up to ± 0.1 mm level) |

Higher (Typically ± 0.2 mm level) |

General (Prone to thermal deformation) |

| Cut Face Quality |

Excellent (High surface finish, minimal or no burrs) |

General (May require deburring) |

Poor (Rough cut face, burnt or discolored areas) |

| Kerf Width |

Narrow (Relatively thin circular blade) |

Extremely Narrow (Minimal material wastage) |

Wide (Thick abrasive wheel, high material loss) |

| Tool Life and Cost |

High tool cost, but long life and low cost per piece |

Low blade cost, but relatively shorter life |

High consumable cost (Fast abrasive wheel wear) |

Zhejiang Sinaida Machine Tools Co., Ltd. specializes in the R&D and manufacturing of CNC saw machines, boasting an annual production capacity of 3,600 units. The company's deep commitment to CNC sawing technology is highlighted by the fact that its CNC sawing machines support China's aerospace industry and are recognized as a qualified supplier by the China Academy of Launch Vehicle Technology, confirming the company's technical strength and product reliability in high-precision, high-stability solutions like the High-Speed Metal Circular Sawing Machine.

Core Technology and Structure of High-Speed Metal Circular Sawing Machine

The ability of the High-Speed Metal Circular Sawing Machine to achieve high-efficiency and high-precision cutting stems from its precise structural design and integrated cutting-edge technology. These technologies ensure that the equipment maintains outstanding rigidity and stability even during high-speed operation.

2.1. Drive System and Saw Blade Technology

2.1.1. High-Speed Spindle Design

The high-speed spindle is the "heart" of the High-Speed Metal Circular Sawing Machine. To achieve the peripheral speed required for high-speed cutting, the spindle typically adopts a high-precision, high-rigidity design, powered by a high-output motor.

- Performance Metrics: Spindle speeds can often reach thousands of revolutions per minute (RPM), and use special bearing configurations to withstand high rotational speeds and significant radial/axial cutting forces.

- Rigidity Assurance: Stability and resistance to vibration during high-speed operation are critical, directly influencing the surface finish ($R_a$) of the cut and the saw blade's lifespan.

2.1.2. Specialized Circular Saw Blade Materials and Geometry

The saw blade is the key "tool" determining cutting quality and efficiency. The blades used in High-Speed Metal Circular Sawing Machine are fundamentally different from traditional blades:

| Blade Feature |

High-Speed Metal Circular Sawing Machine Specialized Blade |

Traditional Friction Saw / Abrasive Wheel |

| Material |

Tungsten Carbide (TCT) or High-Speed Steel (HSS) |

Friction steel, composite materials |

| Cutting Principle |

Milling principle; chips are continuous or spiral |

Friction/Grinding principle; high heat generation, many sparks |

| Tooth Geometry |

Professional tooth profiles designed for different materials (e.g., PVD coating, complex angles) |

No complex geometry, relies on high peripheral speed |

| Cutting Speed |

High, but precisely controlled |

Extremely High, but precision is difficult to manage |

2.2. Feeding and Clamping Mechanisms: Ensuring Stability During High-Speed Cutting

2.2.1. Precision Servo Feeding System

The smoothness and accuracy of the feeding system are paramount during high-speed cutting. The High-Speed Metal Circular Sawing Machine employs high-response, high-precision servo motors coupled with ball screws or rack-and-pinion systems to achieve a constant and precise feed rate.

- Servo Control Advantage: Capable of real-time adjustment of the feed rate based on changes in workpiece material and diameter, preventing saw blade vibration or tooth chipping caused by uneven force.

- Cutting Tolerance: Precise feed control is the foundation for maintaining length tolerances within the ± 0.1 mm range.

2.2.2. High-Rigidity Clamping Device

Under the high-speed, high-force cutting action, the workpiece must be firmly clamped to prevent vibration or displacement.

- Clamping Principle: Mostly uses hydraulic or hydro-pneumatic boosting systems to provide powerful and stable clamping force.

- Multi-Point Support: Typically designed with multiple clamping points (e.g., side clamps and vertical clamps) to ensure zero movement of the workpiece throughout the cutting process.

Zhejiang Sinaida Machine Tools Co., Ltd., with its well-equipped facilities and advanced production technology, is capable of undertaking the design and production of extra-large customized models. The company incorporates high-rigidity design into its entire product line, ensuring its equipment can cope with the massive forces generated during high-speed cutting, which is a key factor enabling their CNC sawing machines to meet the stringent quality requirements, such as those set by the China Academy of Launch Vehicle Technology.

2.3. Cooling and Lubrication Systems: A Necessity for High-Speed Operation

High-speed cutting generates a significant amount of heat. If this heat is not effectively dissipated, it will dramatically reduce saw blade life, cause thermal deformation of the workpiece, and even affect the machine's mechanical precision.

- Minimum Quantity Lubrication (MQL): Modern High-Speed Metal Circular Sawing Machine commonly adopt MQL systems. This system precisely sprays a minute amount of oil mist into the cutting zone, providing both cooling and lubrication, which effectively reduces environmental pollution and subsequent cleaning costs.

- High-Efficiency Coolant Circulation: For heavy-duty or large-diameter cutting, high-pressure, high-flow cutting fluid may be used to rapidly remove heat and flush chips.

Since Zhejiang SINAIDA Machine Tools Co., Ltd.'s products are widely used for cutting ferrous and non-ferrous metals, its equipment must be equipped with efficient thermal management systems and reliable lubrication solutions to ensure optimal performance and maximum tool life when cutting different types of metals.

Performance Advantages and Application Scenarios of High-Speed Metal Circular Sawing Machine

The value of the High-Speed Metal Circular Sawing Machine lies in its revolutionary combination of cutting speed, precision, and reliability. These advantages make it indispensable in many critical manufacturing sectors.

3.1. Ultimate Cutting Efficiency (High-Speed)

The efficiency gain provided by the High-Speed Metal Circular Sawing Machine is its most compelling feature when compared to traditional sawing methods. Its high efficiency results from the high-speed milling principle and automated feeding systems.

| Comparison Metric |

High-Speed Metal Circular Sawing Machine (Typical) |

Traditional Band Sawing Machine (Typical) |

| Cutting Time (Example: Φ 100 mm Carbon Steel Bar) |

5 – 15 seconds/cut |

30 – 120 seconds/cut |

| Potential Daily Output Increase |

200% - 400% |

Baseline |

| Level of Automation |

Standard automatic loading, automatic counting |

More manual or semi-automatic |

This ultimate high efficiency allows manufacturing companies using High-Speed Metal Circular Sawing Machine to significantly reduce the cutting cost per unit product, making it particularly suitable for high-volume, highly repetitive production environments.

3.2. Superior Cutting Precision and Surface Quality

The increase in efficiency does not come at the expense of precision, which is the key differentiator of the High-Speed Metal Circular Sawing Machine from other high-speed cutting methods. The precision spindle and high-rigidity clamping system ensure the final geometry of the workpiece.

- Length Tolerance: Under precise servo control, the cutting length tolerance can typically be maintained within ± 0.1 mm or even more precise ranges.

- Perpendicularity: The perpendicularity of the cut end face to the workpiece axis is extremely high, effectively reducing the setup time for subsequent turning or milling operations.

- Surface Finish: The cut surface is flat and has a high surface finish (low roughness value), often allowing it to proceed directly to heat treatment or finishing, eliminating deburring and face-milling steps.

3.3. Key Application Areas

Due to its perfect balance of high precision and high efficiency, the High-Speed Metal Circular Sawing Machine is widely used in industries with extremely high requirements for component quality.

- Automotive Component Manufacturing: Suitable for cutting round bars or tubes for drive shafts, camshafts, piston pins, and other parts requiring precise blank dimensions.

- Aerospace and Defense: Cutting high-performance alloy materials, which demand extremely high integrity and cutting precision.

- Hydraulic/Pneumatic Components: Providing high-precision blanks for valve bodies, hydraulic cylinders, and other components, reducing subsequent machining allowance.

The CNC sawing machines provided by Zhejiang Sinaida Machine Tools Co., Ltd. can meet the most stringent industry standards due to their high quality and reliability. The company's recognition as a qualified supplier by the China Academy of Launch Vehicle Technology fully substantiates its capability to deliver stable, reliable sawing solutions, including the High-Speed Metal Circular Sawing Machine, for fields that demand stringent requirements for precision and efficiency. The company holds the honor of being a National High-tech Enterprise and a Provincially Recognized Innovative Enterprise, ensuring its product technology continues to advance and lead the market's evolving demand for advanced equipment.

Selection and Maintenance Essentials for High-Speed Metal Circular Sawing Machine

To maximize the efficiency and precision benefits of the High-Speed Metal Circular Sawing Machine, users must conduct careful considerations during selection and implement strict maintenance procedures during daily operation.

4.1. Selection Criteria for High-Speed Metal Circular Sawing Machine

Selecting the right High-Speed Metal Circular Sawing Machine should be based not only on budget but also on production needs, material characteristics, and the required level of automation integration.

| Selection Consideration Factor |

High-Speed Metal Circular Sawing Machine Parameter Requirement |

| Material to be Cut |

Spindle Power and Torque: Higher power needed for hard ferrous metals; higher speed needed for non-ferrous metals. |

| Cutting Size Range |

Maximum Cutting Diameter/Section Size: Must cover the largest specifications of workpieces in production. |

| Daily Output Requirement |

Level of Automation: Determines whether fully automatic bar feeding systems, automatic length measurement, and sorting systems are needed. |

| Cutting Precision Demand |

Feed System Accuracy: Verify the use of high-precision servo systems and high-rigidity structure. |

Zhejiang SINAIDA Machine Tools Co., Ltd., with its capability to undertake the design and production of extra-large customized models, can offer tailor-made High-Speed Metal Circular Sawing Machine solutions based on specific customer requirements for materials (ferrous, non-ferrous, plastics, etc.) and output. The company's strong technical capabilities and advanced production technology ensure its equipment meets diverse selection needs.

4.2. Routine Maintenance of High-Speed Metal Circular Sawing Machine

High-performance equipment requires careful maintenance to sustain its peak performance and longevity, especially in high-speed operating environments.

4.2.1. Correct Saw Blade Installation and Timely Regrinding

The saw blade is the core consumable of the High-Speed Metal Circular Sawing Machine. Its condition directly determines cutting quality and production efficiency.

- Installation: Ensure the saw blade is mounted precisely on the spindle, avoiding runout, which is fundamental to reducing vibration and extending blade life.

- Regrinding: Carbide (TCT) blades should be sent to professional services for precise regrinding when they reach their predetermined lifespan or when cutting quality deteriorates, to restore their milling performance.

4.2.2. Inspection and Replenishment of Lubrication System

Regularly check the MQL or coolant circulation system to ensure the oil/fluid level is sufficient and clean, preventing damage to the equipment and saw blade from excessive frictional heat.

- Oil Circuit Cleanliness: Keep the oil lines and nozzles clear to ensure the lubricant is precisely delivered to the cutting area.

4.3. Trends in Intelligence and Automation

Modern manufacturing strives for "smart factories," and the development of the High-Speed Metal Circular Sawing Machine closely follows this trend.

- Integrated CNC Control: Enables precise digital control over all parameters, including cutting speed, feed rate, and clamping pressure.

- Internet of Things (IoT) Applications: Machines are beginning to integrate sensors and data acquisition modules for real-time production data monitoring, remote fault diagnosis, and predictive maintenance.

Zhejiang SINAIDA Machine Tools Co., Ltd. possesses an excellent management and R&D team, allowing it to keep pace with global sawing technology trends. The company integrates the latest CNC technology and intelligent features into its equipment, ensuring its products are well received in both domestic and international markets and maintain its leading position in the CNC sawing sector.

FAQ

Q1: What materials can the High-Speed Metal Circular Sawing Machine cut?

A: The High-Speed Metal Circular Sawing Machine has high material adaptability, but requires the selection of the correct saw blade material and coating based on the material's hardness and chemical properties.

- Ferrous Metals: Suitable for carbon steel, alloy steel, stainless steel, etc. For high-strength steels, high-quality Carbide (TCT) blades are typically required, along with a robust clamping and drive system.

- Non-Ferrous Metals: Suitable for aluminum alloys, copper, and their alloys. When cutting non-ferrous metals, higher spindle speeds and specific tooth geometries are often used to ensure a clean cut face without material adhesion.

- Other Materials: Certain models can also be used for cutting plastics like non-metallic materials.

Zhejiang SINAIDA Machine Tools Co., Ltd.'s sawing products are widely used for cutting ferrous and non-ferrous metals, plastics, and other non-metallic materials. Company experience ensures its equipment can achieve high-efficiency cutting for various materials through precise parameter settings and saw blade matching.

Q2: How can the service life of the High-Speed Metal Circular Sawing Machine's saw blade be extended?

A: The saw blade is a significant part of the operating cost, and extending its life is crucial for maximizing the equipment's return on investment.

- Correct Cutting Parameters: It is essential to strictly follow the manufacturer's recommendations for feed rate and spindle speed to avoid "aggressive" cutting, which can lead to tooth chipping or excessive wear.

- Efficient Cooling and Lubrication: Ensure the MQL or coolant system is operating correctly and efficiently controlling the cutting temperature, as high temperature is the primary cause of Carbide saw blade failure.

- Timely Professional Regrinding: When the saw blade shows slight wear and the cutting quality has not yet severely deteriorated, it should be sent to a specialist for regrinding. Professional regrinding restores the blade's original cutting geometry, allowing its life to be recycled.

Q3: What is the main cost advantage of the High-Speed Metal Circular Sawing Machine compared to a band saw machine?

A: Although the initial equipment investment for a High-Speed Metal Circular Sawing Machine is generally higher than that of a traditional CNC band saw machine (Zhejiang SINAIDA Machine Tools Co., Ltd. is also a professional CNC band saw manufacturer), its overall cost advantage is primarily found in:

| Cost Dimension |

High-Speed Metal Circular Sawing Machine |

Traditional CNC Band Sawing Machine |

| Cutting Time per Piece |

Extremely Short |

Relatively long |

| Subsequent Machining Cost |

Extremely Low or Zero (High surface finish, no face-milling needed) |

Higher (Often requires deburring or end face finishing) |

| Material Loss |

Low (Narrow kerf, less scrap) |

Lowest (Band saw blade is thinnest) |

| Labor Cost |

Low (High automation, can run unattended for long periods) |

Relatively higher (Lower level of automation) |

From the long run, the High-Speed Metal Circular Sawing Machine offers a higher return on investment by significantly reducing the total manufacturing cost per piece through its high efficiency, low scrap rate, and reduction in subsequent process steps.

Zhejiang Sinaida Machine Tools Co., Ltd., as a Provincially Recognized Innovative Enterprise, focuses on providing high-value-added sawing solutions to customers. The company's strong R&D team is dedicated to optimizing equipment performance, helping users find the best balance between efficiency and cost.