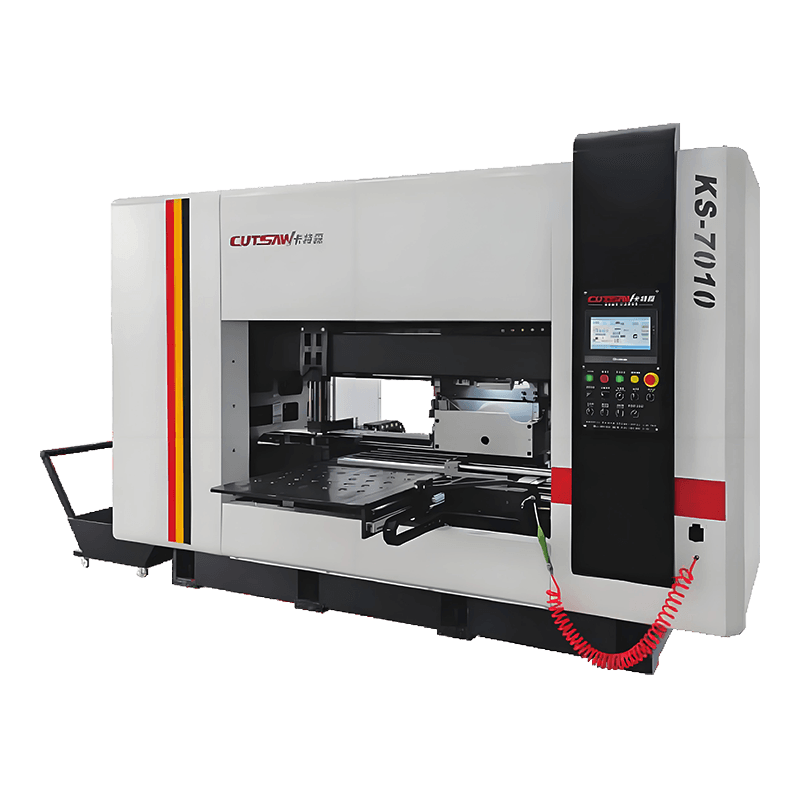

Tilt and Multi-Angle Cutting Capabilities of High-Speed Metal Plate Sawing Machines

Introduction to High-Speed Metal Plate Sawing

High-speed metal plate sawing machines are essential in metal fabrication and processing industries where precision and efficiency are required. Manufacturers like SINAIDA, which produce CNC band saw machines with an annual capacity of 3,600 units and offer custom design services for extra-large models, focus on developing machines that can handle a variety of materials, including ferrous and non-ferrous metals, plastics, and other non-metallic substances. Tilt cutting and multi-angle cutting are important capabilities for applications requiring complex geometries or angled joints, enabling manufacturers to expand production flexibility and meet specific project requirements.

Tilt Cutting Functionality

Tilt cutting, also known as miter cutting, allows the saw head or worktable to pivot at a specified angle, providing the ability to cut metal plates at precise inclinations. High-speed metal plate sawing machines from SINAIDA are designed with adjustable tilting mechanisms that enable operators to set the desired cutting angle with accuracy. This function is critical for producing beveled edges or angled components, commonly required in construction, machinery, and metal assembly applications. The integration of tilt cutting enhances the versatility of the sawing machine, allowing it to perform tasks that would otherwise require separate equipment or additional manual labor.

Multi-Angle Cutting Capabilities

Multi-angle cutting extends the tilt cutting functionality by allowing the saw to cut at a variety of angles without repositioning the workpiece multiple times. This capability is achieved through adjustable saw head geometry, precise control systems, and CNC programming. SINAIDA's high-speed metal plate sawing machines incorporate CNC control technology that enables operators to define multiple cutting angles, optimizing workflow and reducing setup time. Multi-angle cutting is particularly useful for producing components with complex profiles, reducing manual errors and increasing overall production efficiency.

Design Considerations for Precision

To support tilt and multi-angle cutting, the design of high-speed sawing machines must consider structural rigidity, accurate angle measurement, and blade stability. SINAIDA integrates high-quality materials and reinforced frames to maintain alignment and reduce vibration during high-speed operation. Precision angle adjustment systems, combined with CNC control, allow operators to set and repeat specific cutting angles reliably. These design features ensure that each cut maintains dimensional accuracy and surface quality, which is especially important for industrial applications where tight tolerances are required.

Application Across Materials

The ability to perform tilt and multi-angle cutting is applicable to a wide range of materials, including ferrous and non-ferrous metals, plastics, and composite non-metallic materials. Different materials require specific blade types, feed rates, and cutting speeds to achieve optimal results. SINAIDA's machines are equipped with adaptable blade and motor configurations that accommodate various material properties, enabling precise angled cuts without compromising efficiency or quality. This adaptability increases the usability of high-speed metal plate sawing machines across diverse industries and production environments.

| Feature |

Function |

Benefits |

| Tilt Cutting |

Adjustable pivoting of saw head or table |

Enables angled cuts for beveled edges and miter joints |

| Multi-Angle Cutting |

CNC-programmable angle adjustments |

Reduces workpiece repositioning, increases production efficiency |

| Precision Control |

High-quality frames and angle measurement systems |

Maintains dimensional accuracy and consistent surface quality |

| Material Adaptability |

Adjustable blades and feed rates |

Supports ferrous, non-ferrous, and non-metallic materials |

Operational Efficiency and Workflow Optimization

Tilt and multi-angle cutting capabilities contribute to overall operational efficiency by reducing the need for secondary cutting operations. Operators can complete complex angled cuts in a single setup, minimizing downtime and enhancing workflow consistency. The CNC control provided in SINAIDA machines allows for precise programming and repeatability, which ensures that multiple workpieces can be processed with identical specifications. This reduces human error, improves safety, and supports high-volume production while maintaining quality standards.

Customization for Specific Requirements

SINAIDA offers the design and production of extra-large customized models, allowing clients to specify tilt and multi-angle cutting ranges according to their unique operational needs. Customization may include extended pivot angles, specialized clamps, and enhanced CNC programming capabilities. By providing tailored solutions, SINAIDA ensures that high-speed metal plate sawing machines meet diverse industry requirements, from standard production tasks to specialized fabrication projects.

Maintenance and Long-Term Performance

Maintaining tilt and multi-angle cutting functionality requires regular inspection and servicing of mechanical pivot systems, CNC controllers, and blade components. SINAIDA emphasizes durable construction, precise assembly, and accessible maintenance points to ensure long-term reliability. Proper care, including lubrication and periodic calibration, allows the saw to maintain cutting accuracy and operational safety over extended use, ensuring that tilt and multi-angle capabilities continue to support diverse production requirements effectively.

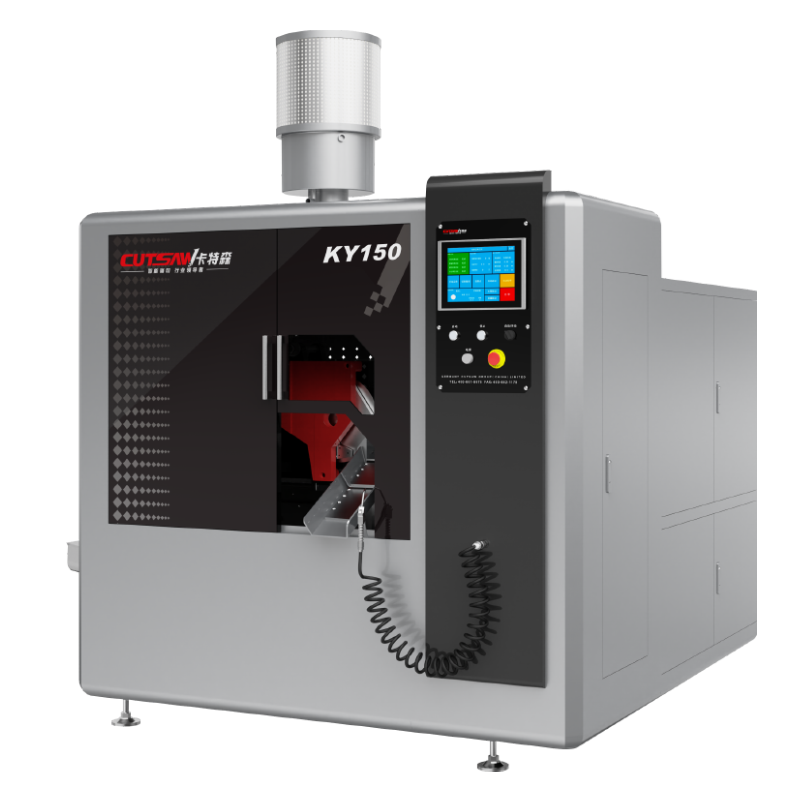

Fault Alarm System in High-Speed Metal Plate Sawing Machines

Introduction to Fault Detection

Fault detection and alarm systems are essential features in modern high-speed metal plate sawing machines, as they allow operators to identify and address issues promptly. SINAIDA, a professional CNC band saw machine manufacturer with an annual production capacity of 3,600 units and the capability to design extra-large customized models, emphasizes integrating such systems into its machines. Fault alarms provide real-time alerts for various operational problems, helping to prevent prolonged downtime and ensuring smooth production processes for cutting ferrous, non-ferrous metals, plastics, and other non-metallic materials.

Components of the Fault Alarm System

A fault alarm system in a high-speed sawing machine typically includes sensors, a control unit, and an alert mechanism. Sensors monitor key parameters such as motor temperature, blade tension, hydraulic pressure, and rotational speed. The control unit interprets signals from these sensors, identifies deviations from normal operating ranges, and triggers an alert if a fault is detected. The alert mechanism may include visual indicators on a display panel, audible alarms, or notifications through connected monitoring systems. SINAIDA incorporates reliable sensors and precise control units to ensure that faults are detected accurately and efficiently.

Types of Detectable Faults

High-speed metal plate sawing machines are exposed to a range of potential issues during operation. Fault alarm systems are designed to detect electrical failures, mechanical misalignments, hydraulic or pneumatic malfunctions, and abnormal blade behavior. Early detection allows operators to intervene before minor problems escalate into major machine failures. SINAIDA's machines are equipped with comprehensive monitoring systems that provide alerts for each of these conditions, enabling operators to perform corrective actions and maintain consistent cutting quality and operational safety.

Integration with CNC Control Systems

The fault alarm system is integrated with the CNC control unit to facilitate real-time monitoring and automated response. When a fault is detected, the system can pause or stop machine operation to prevent further damage or safety risks. SINAIDA's CNC-based band saw machines use this integration to improve reliability and minimize manual inspection requirements. Operators can access detailed fault codes, troubleshoot issues, and make adjustments through the CNC interface, which streamlines maintenance processes and reduces downtime.

Benefits for Production Efficiency

Implementing a fault alarm system enhances overall production efficiency by minimizing unexpected stoppages and enabling timely maintenance. With real-time alerts, operators can respond quickly to mechanical or electrical irregularities, maintaining smooth workflow and reducing potential losses. SINAIDA’s integration of fault detection systems ensures that high-speed metal plate sawing machines can sustain continuous operation in demanding industrial environments, providing consistent cutting performance for a variety of materials.

| System Component |

Function |

Benefit |

| Sensors |

Monitor temperature, tension, speed, and pressure |

Early detection of operational deviations |

| Control Unit |

Interpret sensor signals and identify faults |

Accurate diagnosis and automated alerts |

| Alert Mechanism |

Visual or audible notifications |

Immediate operator response and reduced downtime |

| CNC Integration |

Interface for fault codes and machine control |

Streamlined troubleshooting and maintenance |

Customization for Industrial Needs

SINAIDA can provide customized fault alarm configurations for extra-large or specialized sawing machines. Depending on the production environment and material types, additional sensors or monitoring features can be incorporated to meet specific operational requirements. Customization ensures that all critical aspects of machine performance are monitored, reducing the risk of unplanned interruptions and supporting precise, reliable sawing for industrial applications.

Maintenance and Longevity Considerations

Regular maintenance of both the sawing machine and its fault alarm system ensures long-term reliability. Sensors and control units should be periodically inspected, cleaned, and calibrated to maintain accurate monitoring. Proper maintenance of mechanical components, hydraulic systems, and electrical connections complements the fault detection system, preventing false alarms and ensuring timely detection of genuine issues. SINAIDA emphasizes robust construction, accessible maintenance points, and user-friendly diagnostic interfaces to support the long-term functionality of both the machine and its monitoring systems.