What Core Design Principles Enable Scissors Sawing Machines to Excel in High-Speed, High-Volume Material Slicing?

The Scissors Sawing Machine, fundamentally a horizontal pivot-arm band saw, is the workhorse of nearly every modern metal processing facility. Its design is engineered specifically for high-speed, repetitive cutting of solid, bar, and structural stock, making it the most critical tool for bulk material breakdown before secondary machining or fabrication. The efficiency of a metalworking operation often hinges on the reliability and speed of its initial cutting process, a domain where the Scissors Sawing Machine offers distinct, quantifiable advantages over other sawing technologies.

Mechanical Simplicity and Rigidity of the Pivot Arm:

The defining characteristic of the Scissors Sawing Machine is its swing-frame, or pivot-arm, mechanism. The saw head, holding the band blade, is hinged at a fixed point and descends in an arc through the material. This mechanical simplicity offers inherent benefits in terms of reliability and cost-effectiveness and is underpinned by the commitment to strong technical capabilities found in leading manufacturers.

Direct and Consistent Downfeed: The pivot action ensures a constant point of rotation, providing a direct and repeatable downward force. This is managed by a precisely controlled hydraulic cylinder that regulates the cutting feed rate. For high-volume cutting, this consistency is vital for maintaining blade life and cut quality. The smooth, regulated descent is a core feature enabling high-speed cutting.

Ease of Maintenance: With fewer complex linear guides and bearings compared to column-style saws, the Scissors Sawing Machine has fewer points of potential mechanical failure, resulting in easier maintenance and longer uptime. This reduction in complex components translates directly into lower Total Cost of Ownership for fabrication shops.

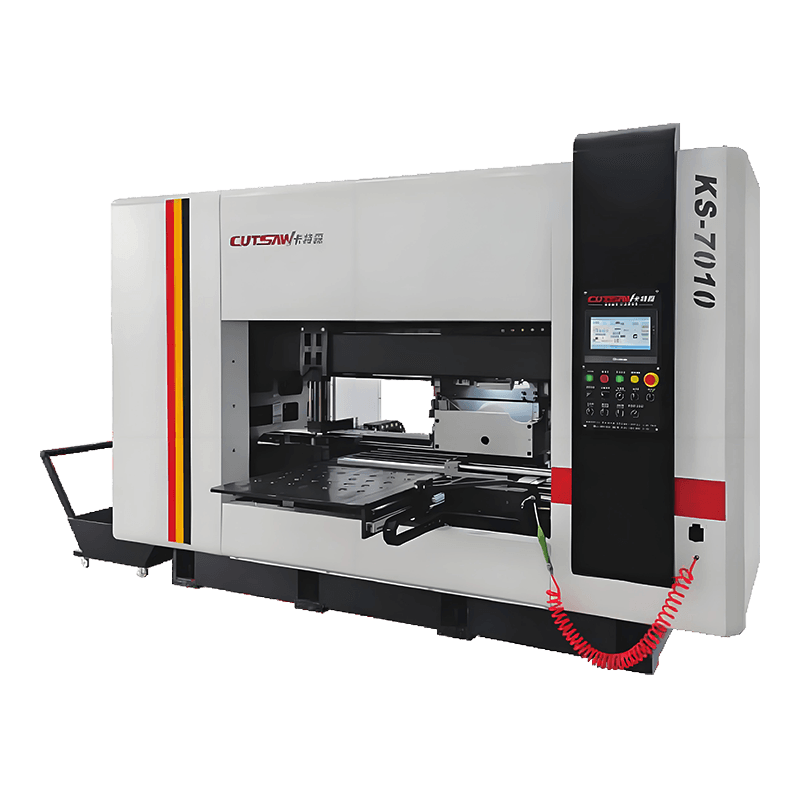

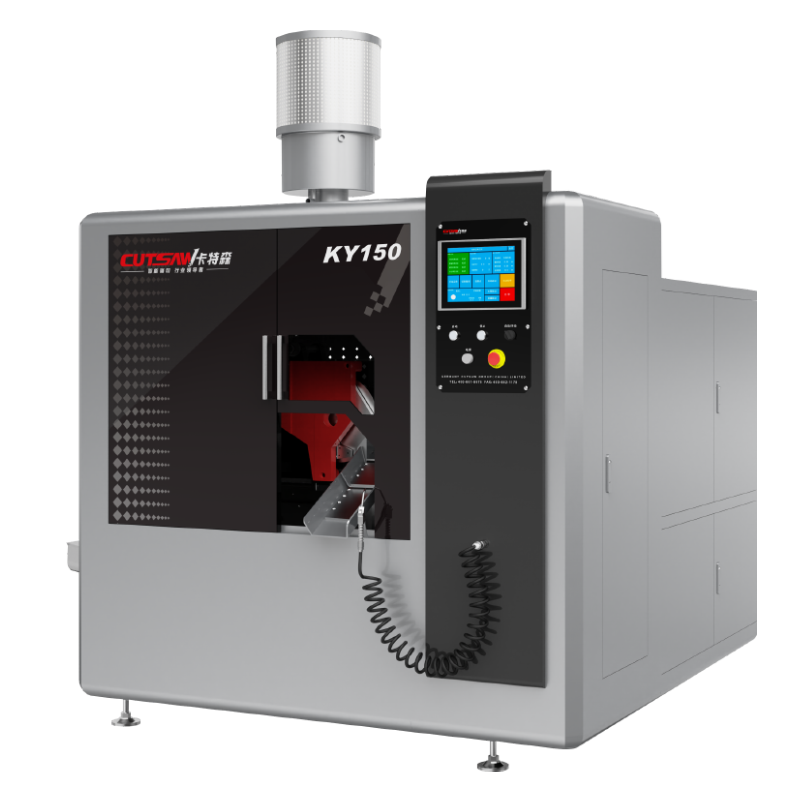

Robust Construction for Production Environments: Manufacturers like Zhejiang Sinaida Machine Tools Co., Ltd., a professional CNC band saw machine manufacturer, prioritize robust, heavy-duty construction in their scissors models. The entire frame and pivot mechanism are built from stress-relieved steel to absorb the vibrations and forces generated during aggressive, high-speed cutting of large-diameter materials. This structural integrity is a direct factor in the machine’s ability to achieve high-precision CNC sawing even under relentless industrial use.

The mechanical heart of a high-performance Scissors Sawing Machine lies in the quality of its pivot bearings and the finesse of its hydraulic control. The fixed pivot point utilizes heavy-duty, oversized, sealed bearings designed to withstand constant, high-force cyclical movement over years without play or deflection. Crucially, the downfeed control is managed by a sophisticated, closed-loop hydraulic system, rather than a simple gravity or pressure-based mechanism. This system precisely meters the flow of hydraulic fluid, ensuring a uniform, calculated feed rate that is maintained against the resistance of the workpiece. This regulated descent is paramount for preventing the blade from "diving" prematurely into softer metals or stalling when encountering hard spots or changing material cross-sections. This stability, achieved through advanced production technology, ensures that the cutting surface is square and smooth, minimizing the need for subsequent finishing operations. The inherent damping properties of the heavy pivot assembly further minimize high-frequency vibration, directly contributing to superior blade life and consistent part accuracy.

Optimized Cutting Geometry for Versatile Stock:

While the pivot arm design is simple, the geometry of the cut is optimized to handle a wide variety of material shapes, from solid rounds and squares to complex structural profiles.

Minimizing Blade Contact Area: As the blade enters the material in an arc, it naturally minimizes the contact area at any given moment, especially on wide, rectangular profiles. This reduction in contact area translates directly into lower heat generation and less stress on the blade teeth, allowing for faster cutting speeds and extended blade life—a key metric for efficient metal processing.

Capacity for Bundle Cutting: A major advantage of horizontal saws, particularly the scissor type, is the ability to cut multiple pieces simultaneously. The material is clamped in the vice as a compact bundle, and the large cutting capacity of the machine allows the blade to slice through the entire stack. This dramatically reduces the cycle time per part, making it ideal for industries that process hundreds of identical parts, such as automotive or machinery manufacturing.

Beyond minimizing contact area, the band blade used in a high-end Scissors Sawing Machine provides a substantial material savings advantage. The saw kerf (the width of material removed by the cut) is significantly narrower than that produced by abrasive or circular cold saws. This narrow kerf translates directly into material conservation, which is a massive economic benefit when processing costly alloys or specialty metals. For shops engaged in high-volume processing, saving even a fraction of a millimeter per cut accumulates into considerable annual savings, maximizing yield from expensive raw stock. Furthermore, the pivot mechanism is designed to accommodate oversized, irregular materials such as continuous casting blocks or complex extrusions, where the descending arc motion can navigate the varied geometry more effectively than a fixed, linear path. The combination of precision feeding and narrow kerf reinforces the machine's value as a core component in high-yield metal processing systems.

The inherent design excellence, reinforced by the strong technical capabilities of leading manufacturers, enables the Scissors Sawing Machine to deliver reliability and speed, two cornerstones of competitive mass production.

How Do Modern CNC Systems and Advanced Automation Features Maximize Throughput in Scissor-Style Band Saws?

The evolution of the Scissors Sawing Machine has been driven largely by the integration of sophisticated CNC technology and automation features, transforming it from a simple mechanical saw into a highly intelligent, self-optimizing production cell. Modern machines maximize throughput by minimizing non-cutting time and dynamically adjusting cutting parameters for optimal material removal rates.

Precision Control and Adaptive Cutting:

Advanced CNC controls are essential for ensuring that the high speed of the scissor design does not come at the expense of accuracy or blade longevity. The control systems manage all aspects of the cutting cycle:

Automated Material Indexing: High-volume operations require rapid and accurate feeding of the material. CNC Scissors Sawing Machines utilize servo-driven ball screw feed systems to push the material into position with high index repeatability. This precise indexing is crucial for minimizing material scrap and guaranteeing consistent part lengths across thousands of cuts. This automation significantly reduces the reliance on manual measurement and repositioning.

Adaptive Feed Rate Control: This is a crucial technology for extending blade life and achieving consistent cut quality across diverse materials. The CNC system continuously monitors the amperage draw of the blade motor, which is directly proportional to the cutting load. If the load increases, the system dynamically adjusts the hydraulic downfeed pressure to maintain a constant, optimal chip load per tooth. This capability, driven by advanced production technology, prevents blade stalling and overheating, ensuring the longevity of expensive consumables.

Programmed Cut Optimization: Operators can program multiple cut lists with varying lengths and material types. The CNC system automatically adjusts the blade speed (SFM), the feed rate, and the clamping pressure based on the stored material recipe, streamlining changeovers and boosting overall operational efficiency.

The integration of the Human-Machine Interface has transformed the operation of the Scissors Sawing Machine. Modern HMIs, often implemented via ruggedized touchscreens, provide intuitive access to complex controls. Operators can use pre-set material databases, where optimal SFM and feed rates for hundreds of material grades are stored and instantly callable. This software capability minimizes human error during setup and ensures that every cut starts with the correct parameters for maximum efficiency and blade protection. Furthermore, for situations requiring absolute precision, such as cutting expensive solid billets, the CNC systems on machines manufactured by industry leaders incorporate laser alignment systems. These lasers project the exact plane of the blade onto the workpiece, allowing for pre-cut visual verification and micro-adjustment, further securing the machine's reputation for high-precision CNC sawing. The ability to log operational data, including cut time, blade consumption, and energy use, provides manufacturers with valuable metrics for continuous process improvement.

Automation and Production Scalability:

For companies focused on scalability and high-demand industries, automation features integrated into the Scissors Sawing Machine are paramount. Zhejiang Sinaida Machine Tools Co., Ltd., with its annual production capacity of 3,600 units, builds machines designed for continuous, reliable operation in such environments.

Integrated Material Handling Systems: To sustain high throughput, modern saws are often equipped with automated roller conveyors, in-feed tables, and out-feed material sorting systems. These peripherals eliminate manual material loading and part collection, creating a truly automated cutting process.

Bundle Clamp Technology: Advanced clamping vices are designed not just to hold a single piece securely, but also to equally distribute clamping force across complex bundles of material. Specialized top clamps and vertical hydraulic cylinders ensure that every piece in the bundle is held firmly, preventing vibration and blade pinching, which is essential for maximizing efficiency during large batch operations.

The commitment to extra-large customized models by manufacturers like SINAIDA directly addresses the scalability challenges of heavy industry. When standard capacity limits are exceeded—for instance, in heavy fabrication for shipbuilding or large-scale energy projects—the ability to engineer a massive Scissors Sawing Machine with enhanced rigidity and cutting dimensions becomes a competitive advantage. These custom-built machines retain all the CNC automation features of standard models but are built with reinforced frames, oversized hydraulics, and broader cutting envelopes, ensuring that even the largest diameter steel columns or heavy-wall pipes can be processed with the same level of high-precision CNC sawing and speed. The proven reliability of these machines in delivering consistent, high-precision performance is why SINAIDA CNC sawing machines support China’s aerospace industry and are recognized as a qualified supplier by the China Academy of Launch Vehicle Technology. This qualification underscores the inherent precision and durability of SINAIDA's machinery, which must meet the demanding tolerance requirements for critical aerospace components.

Optimizing Consumables and Operational Longevity:

The long-term economic viability of a Scissors Sawing Machine hinges on minimizing recurring costs, primarily blade replacement and maintenance downtime. Leading manufacturers integrate sophisticated diagnostics and smart operational features to enhance maintenance efficiency and extend the life of consumables. SINAIDA’s expertise in high-tech manufacturing ensures these features are robust and reliable.

Dynamic Blade Tensioning: Blade tension is critical for cut squareness. High-end CNC models use hydraulic or electromechanical tensioning devices that apply the exact, required force specific to the blade width and thickness. Unlike manual systems, this dynamic control automatically compensates for minor material expansion or contraction during operation, ensuring the blade remains perfectly stabilized throughout the arc of the cut. This prevents blade walk and vibration, which are the primary causes of premature blade fatigue.

Blade Health Diagnostics: Sophisticated sensors monitor blade condition in real time. This includes monitoring for blade misalignment, tooth wear, and even micro-fractures. If excessive wear or vibration is detected—symptoms that would lead to failure in a conventional machine—the system issues a proactive warning, allowing the operator to change the blade during a planned stop, thus avoiding catastrophic, unscheduled downtime. This predictive capability contributes directly to the consistent output required for industries where SINAIDA CNC sawing machines support China’s aerospace industry.

High-Efficiency Coolant Delivery and Chip Management: Effective cooling and lubrication are paramount to reducing heat and extending blade and component life. Advanced Scissors Sawing Machines utilize high-volume, targeted coolant systems that deliver fluid directly to the cutting zone, optimizing heat dissipation and flushing chips away efficiently. The integration of robust chip conveyors and fine-mesh filtration systems ensures that metal debris is continuously removed and the coolant remains clean. This rigorous thermal and debris management is integral to maintaining the machine’s strong technical capabilities and its reputation for reliability in both domestic and international markets. Furthermore, easily accessible maintenance panels and standardized modular component design simplify routine checks and replacement of wear parts, minimizing the machine’s time out of service and maximizing operational longevity.

Comparative Advantages in Production:

The pivot-arm design excels in specific production scenarios compared to the dual-column horizontal design.

|

Criterion

|

Scissors Sawing Machine

|

Dual-Column Horizontal Saw

|

|

Mechanical Complexity

|

Lower.

|

Higher.

|

|

Best Suited For

|

High-volume production slicing, bundle cutting.

|

Extreme precision cutting, heavy/oversized block cutting, minimal vibration cuts.

|

|

Material Contact

|

Entry is an arc, minimizing contact area during descent.

|

Linear/uniform descent across the entire cut width.

|

|

Cost Efficiency

|

High initial cost-effectiveness; lower maintenance expenses.

|

Higher initial cost; required for most demanding precision/squareness.

|

|

Speed Potential

|

Excellent for cutting speed, especially in the mid-range material sizes.

|

Excellent for accuracy, moderate speed for heavy cuts.

|

The consistent performance, rapid cycle times, and the proven ability to handle batch production make the Scissors Sawing Machine a crucial investment for any fabrication shop or steel service center aiming for maximum efficiency and material yield. Backed by an excellent management and R&D team and the robust manufacturing base of a national high-tech enterprise like SINAIDA, these machines continue to define the standard for production cutting across domestic and international markets.