Why the Constant Load CNC Band Sawing Machine is Necessary

Challenges and Pain Points of Traditional Band Saws

In modern industrial manufacturing, the precision and efficiency of material cutting are critical indicators of productivity. Traditional band saws exhibit inherent flaws that become increasingly pronounced when dealing with high-strength, high-value specialty metals, such as those used in the aerospace industry.

Traditional band saws primarily use constant feed pressure or constant feed speed for cutting. However, this control method suffers from severe limitations:

- Impact of Feed Force/Pressure Fluctuation on Cut Quality, Efficiency, and Blade Life

- When the saw blade enters the workpiece or the cutting cross-section suddenly increases, the cutting resistance rises sharply. This causes the blade to become overloaded and overheat, leading to tooth chipping and significantly shortening the blade life.

- When the blade exits the workpiece or the cutting cross-section suddenly decreases, the cutting resistance drops abruptly. This often generates vibration and a “chattering” phenomenon, resulting in high surface roughness and affecting subsequent processing.

- Limitations of Manual Adjustment when Cutting Different Materials or Thicknesses

- Operators must frequently adjust feed parameters based on experience. This manual adjustment is time-consuming and struggles to achieve the ideal, sustained cutting condition.

- Traditional machines cannot respond in real-time to material variations when cutting materials with uneven hardness or large castings.

Introduction and Value of the "Constant Load" Concept

To overcome the shortcomings of traditional band saws, the Constant Load CNC Band Sawing Machine was developed.

- Definition: The Core of Constant Load

The focus shifts from controlling “how to feed” to controlling “the magnitude of the cutting force.” Constant Load refers to the use of advanced CNC systems to monitor the actual cutting force or torque between the blade and the workpiece in real-time, precisely maintaining it within an ideal, preset optimal working range.

- Key Advantage Parameter Comparison

| Traditional Band Saw (Constant Pressure/Speed) |

Constant Load CNC Band Sawing Machine |

Notes |

| Control Variable |

Actual Cutting Force/Torque |

|

| Load State |

Fluctuates, prone to overload |

Continuously stable, maintains optimal value |

| Blade Life |

Lower (prone to fatigue due to instantaneous overload) |

Significantly increased (20% or more) |

| Cutting Efficiency |

Difficult to consistently maximize |

Sustained high efficiency (always runs at the maximum constant load allowed) |

| Cut Surface Quality |

Prone to chatter marks and inconsistent roughness |

High flatness, excellent consistency |

- Initial Positioning of the Constant Load CNC Band Sawing Machine

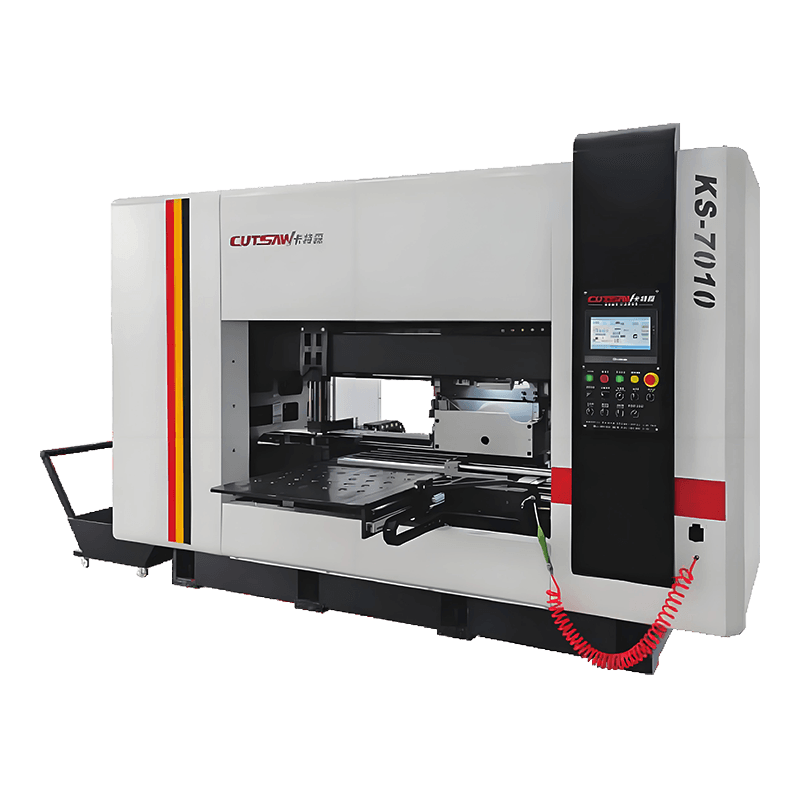

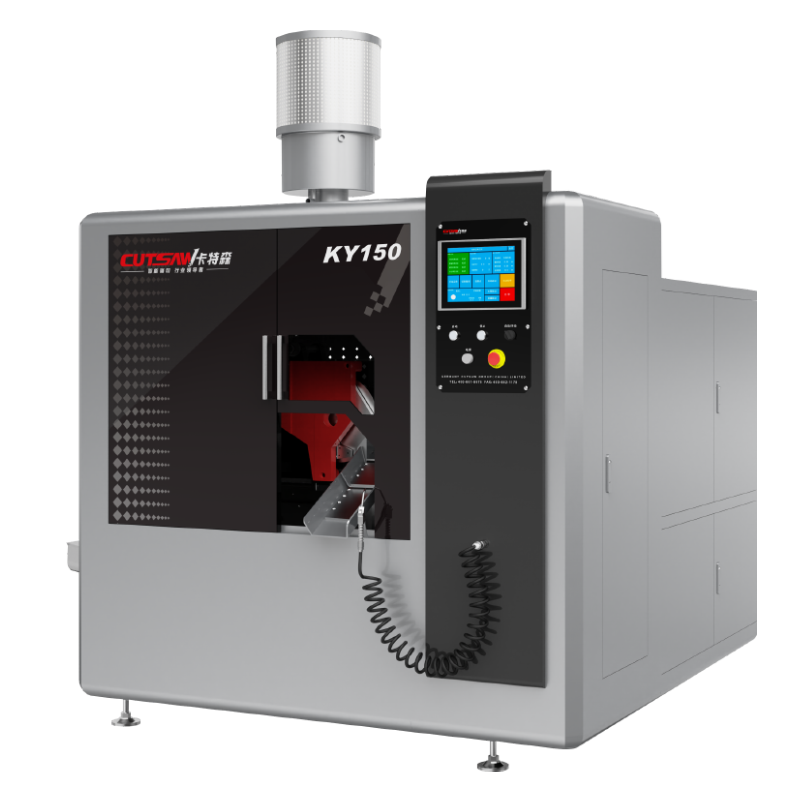

Zhejiang Sinaida Machine Tools Co., Ltd. deeply understands the importance of high-quality sawing for modern industry. As a National High-Tech Enterprise and a provincially recognized innovative enterprise, established on December 8, 2000, and located at No. 152 Xinggong Road, Huzhen Town Industrial Park, Jinyun County, Lishui City, Zhejiang Province, the company has always focused on the R&D and manufacturing of professional CNC band saw machines.

Driven by an insight into the demand for precision sawing, Zhejiang Sinaida Machine Tools Co., Ltd. introduced the Constant Load CNC Band Sawing Machine. This machine is a key technology for achieving high-quality, high-efficiency automated sawing, ensuring that the cutting force is optimized at every moment of the sawing process, providing customers with stable, efficient, and precise processing solutions.

Technical Analysis: Operating Principle of the Constant Load CNC Band Sawing Machine

The ability of the Constant Load CNC Band Sawing Machine to achieve revolutionary sawing performance lies in its closed-loop control system, a fundamental difference from traditional open-loop or semi-closed-loop systems. Zhejiang Sinaida Machine Tools Co., Ltd. leverages its strong technical capability and excellent R&D team to perfectly combine complex sensor technology with high-precision CNC control, ensuring the reliability of the Constant Load function.

Core System I: High-Precision Sensors and Feedback Mechanism

The starting point of Constant Load control is the precise perception of the cutting state:

- Real-time Monitoring Technology: Equipment from Zhejiang Sinaida Machine Tools Co., Ltd. integrates highly sensitive sensors to collect critical data during the sawing process in real-time, such as:

- Feed Reaction Force (Cutting Resistance): Directly reflects the actual load on the saw teeth.

- Main Spindle Motor Torque: Indirectly reflects the load change on the saw blade during cutting.

- High-Speed Data Acquisition and Transmission: The sensors quickly convert the analog signals into digital signals and transmit them at an extremely high frequency to the Intelligent CNC Control System. The CNC system will constantly compare the real-time cutting force with the preset “ideal Constant Load value,” generating an error signal.

Core System II: Intelligent CNC Control and Drive

The Intelligent CNC Control System acts as the “brain” and “executor” for achieving Constant Load.

- Intelligent CNC Control:

- Constant Load Algorithm: The CNC system of Zhejiang Sinaida Machine Tools Co., Ltd. features proprietary intelligent algorithms. These algorithms do not simply pursue a constant value but calculate the precise feed rate required for the next moment in real-time, based on the material characteristics, blade parameters, and the set Constant Load target.

- Millisecond-Level Response: The CNC system must respond to the error signal from the sensor within milliseconds, generating correction commands for the feed system.

- Role of the Servo Feed System:

- High-Precision Execution: Unlike traditional hydraulic or frequency-controlled drives, the Constant Load machine employs a high-performance servo drive system to control the feed of the saw frame. Servo motors offer extremely high precision and dynamic response speed, allowing them to accurately execute the correction commands from the CNC system.

- Ensuring Constant Load: When the real-time load is above the set value, the CNC instructs the servo system to immediately slow down the feed rate; when the real-time load is below the set value, the CNC instructs the servo system to immediately speed up the feed rate. Through this dynamic, precise adjustment, the cutting force is locked into the ideal constant range.

Therefore, the Constant Load CNC Band Sawing Machine from Zhejiang Sinaida Machine Tools Co., Ltd. effectively achieves intelligent variable-speed sawing under constant cutting force. This high-dynamic, high-precision control technology is a key technical foundation that enables the company's products to be recognized by the Chinese aerospace industry and listed as a qualified supplier by the China Academy of Launch Vehicle Technology.

Practical Application Advantages of the Constant Load CNC Band Sawing Machine

The technical advantages of the Constant Load CNC Band Sawing Machine ultimately translate into increased production efficiency and cost control for the customer. Zhejiang SINAIDA Machine Tools Co., Ltd., with its deep technical accumulation and advanced production technology, ensures that its equipment delivers stable and outstanding sawing performance to users.

Key Application Advantages and Data Comparison

Thanks to the closed-loop control of the Constant Load technology, machines from Zhejiang SINAIDA Machine Tools Co., Ltd. surpass traditional sawing equipment in several dimensions:

| Performance Indicator |

Constant Load CNC Band Sawing Machine |

Traditional CNC Band Saw Machine |

Constant Load Mechanism |

| Blade Life Improvement |

20% – 50% or higher |

Susceptible to material and operational fluctuations |

Eliminates instantaneous high-stress peaks and tooth fatigue, keeping the blade working in the optimal stress zone. |

| Cutting Efficiency Stability |

Maximized and stable (±2% fluctuation) |

High fluctuation (±10% - 20% fluctuation) |

System adjusts the feed speed in real-time, ensuring operation at the maximum constant load allowed by the material and blade. |

| Surface Roughness (Ra) |

Can be reduced by approximately 30% |

Prone to vibration marks due to feed fluctuation |

Eliminates sudden changes in feed force, significantly reduces vibration of the saw frame and blade, and improves surface flatness. |

| Single Cut Precision |

Higher (±0.1∼0.2 mm) |

More susceptible to material internal stress release |

Smooth and uniform cutting process reduces workpiece deformation caused by uneven stress. |

Adaptability to Complex Materials: Assurance for Aerospace-Grade Sawing

For those materials that are difficult to machine, such as superalloys, nickel-based alloys, titanium alloys, and various tool steels, the Constant Load technology proves invaluable and irreplaceable.

- Constant Load High Adaptability: These materials are typically characterized by high hardness and toughness, making them highly sensitive to cutting forces. On traditional saws, large variations in cutting hardness often lead to "welding" or "tooth breakage."

- The Constant Load CNC Band Sawing Machine from Zhejiang SINAIDA Machine Tools Co., Ltd. uses intelligent algorithms to sense subtle changes in material hardness in real-time, immediately adjusting the feed speed to prevent heat and stress concentration.

- Professional Certification: The CNC sawing machines from Zhejiang SINAIDA Machine Tools Co., Ltd. support the development of China’s aerospace industry and are recognized as a qualified supplier by the China Academy of Launch Vehicle Technology. This honor fully demonstrates the company's exceptional capability in processing high-value, special materials that demand extreme precision and reliability, with Constant Load technology being the key assurance for achieving this high standard of sawing.

Optimization for Automation and Batch Production

As a professional CNC band saw machine manufacturer with an annual production capacity of 3,600 units, Zhejiang SINAIDA Machine Tools Co., Ltd. is well aware of the stability requirements for mass production.

- Extremely High Degree of Automation: Once the ideal Constant Load value is set, the machine can autonomously optimize the process. Whether for single-piece cutting or continuous batch cutting, the system fully monitors and adjusts the process, significantly reducing operator intervention and human error.

- Data Traceability: The CNC system of a Constant Load machine typically records the load curve, speed changes, and other data throughout the cutting process. This provides valuable data for users to perform quality control and process optimization.

By combining high-precision technology and large-scale production experience, the Constant Load CNC Band Sawing Machine from Zhejiang SINAIDA Machine Tools Co., Ltd. not only achieves a performance leap but also delivers tangible economic benefits to domestic and international customers: longer blade life, faster cutting speed, and more reliable processing quality.

Selection and Maintenance: Maximizing the Value of the Constant Load CNC Band Sawing Machine

Even with the most advanced Constant Load CNC Band Sawing Machine, proper selection and maintenance are crucial to ensure its long-term efficient operation. Zhejiang SINAIDA Machine Tools Co., Ltd. not only is committed to providing high-performance equipment, but also to offering systematic application guidance to help customers fully unlock the potential of Constant Load technology.

How to Choose the Right Constant Load CNC Band Sawing Machine

When evaluating and purchasing a Constant Load CNC band sawing machine, attention should be focused on the quality of the control system and the overall adaptability of the equipment.

- Core Evaluation I: Precision and Response Speed of the Constant Load Control System

- Key Metrics: Evaluate the machine’s response time during load fluctuations (ideally millisecond level) and the load maintenance precision (i.e., the deviation range between the actual load and the target load).

- Zhejiang SINAIDA Machine Tools Co., Ltd. has strong technical capabilities and well-equipped facilities. Its Constant Load system is meticulously designed and tuned to ensure stable and reliable control accuracy under various demanding cutting conditions.

- Core Evaluation II: Mechanical Structure and Material Compatibility

- Assess the maximum cutting size and the range of processable materials (ferrous metals, non-ferrous metals, non-metallic materials).

- As a National High-Tech Enterprise, the products of Zhejiang SINAIDA Machine Tools Co., Ltd. have passed ISO9001 Quality Management System Certification, China Machinery Safety Certification, and EU CE Certification, confirming the stability and safety of their mechanical structure with international recognition.

Optimizing the Operating Environment for Constant Load

To match the high efficiency of Constant Load operation, the saw blade and cooling systems also require corresponding optimization:

- Saw Blade Selection and Matching:

- Complementing Constant Load: The use of high-quality bi-metal or carbide saw blades is recommended. Since Constant Load eliminates sudden stress peaks on the blade, users can select a finer tooth pitch or higher tooth tip hardness to improve cutting speed and finish, maximizing the benefits of constant cutting force.

- Importance of the Coolant System:

- Zhejiang SINAIDA Machine Tools Co., Ltd. advises users to ensure stable coolant flow and concentration. While heat generation is relatively stable under constant cutting load, the demand for cooling efficiency increases as the feed speed accelerates. Excellent cooling further extends the blade life.

Key Daily Maintenance Points for the Constant Load System

System maintenance focuses on ensuring accurate data input and precise command output.

| Maintenance Area |

Maintenance Content |

Maintenance Purpose |

| Load Sensors |

Regular cleaning and calibration |

Ensures the cutting force data fed back to the CNC is accurate, which is the foundation of Constant Load control. |

| Servo Drive and Feed Mechanism |

Check lubrication of the drive motor, lead screw, and guide rails |

Ensures the feed system has extremely high sensitivity and response speed to accurately execute CNC adjustment commands. |

| CNC Control System |

Regularly back up parameters, check for software updates |

Ensures the stable operation of the Constant Load algorithm and prevents control failure due to parameter loss. |

Zhejiang SINAIDA Machine Tools Co., Ltd. has advanced production technology and a complete after-sales service system, able to provide comprehensive technical support and maintenance guidance to customers. This helps maintain the optimal performance of their Constant Load CNC Band Sawing Machine and maximizes the processing value delivered by the company as a professional CNC band saw machine manufacturer. The company is uniquely positioned to undertake the design and production of extra-large customized models, meeting the most demanding Constant Load sawing requirements of its clients.

FAQ

- Q1: Is the Constant Load CNC Band Sawing Machine just a gimmick? What is the fundamental difference between it and an ordinary CNC band saw?

A1: It is by no means a gimmick, but a structural upgrade to sawing technology. The fundamental difference lies in the control variable:

- Ordinary CNC Machine: Controls the input variable (e.g., constant feed speed or constant pressure). When material hardness changes, the actual cutting force (output variable) fluctuates severely.

- Constant Load CNC Band Sawing Machine: Directly controls the core output variable (i.e., constant cutting force/load). It actively counteracts the effects of material or cross-section changes by adjusting the feed speed in real-time.

The Constant Load machines provided by Zhejiang SINAIDA Machine Tools Co., Ltd. ensure stability and repeatability in the sawing process that is difficult for traditional machines to achieve.

- Q2: Does the Constant Load feature increase cutting time? How does it improve efficiency?

A2: Usually does not; on the contrary, it improves overall efficiency.

- While the machine may temporarily slow down when cutting certain hard sections to maintain Constant Load, this prevents blade damage and shutdowns due to overload.

- When cutting softer or thinner sections, the machine will automatically accelerate, ensuring it always runs at the maximum safe cutting force allowed by the blade and material. This results in the highest possible average sawing efficiency. This is the continuous, stable, and highly efficient operating mode provided by the Constant Load technology.

- Q3: Why is Constant Load technology particularly important for cutting aerospace materials?

A3: Aerospace materials (such as titanium and nickel-based alloys) are often high-value, high-strength, and sensitive to heat.

- Any minor fluctuation in cutting force can lead to micro-cracks in the material, rapid tool wear, or even scrap the entire workpiece. Constant Load technology ensures that the cutting force is precisely constant, keeping heat and stress within safe limits.

- Zhejiang SINAIDA Machine Tools Co., Ltd. has advanced management and R&D teams. The company's ability to be recognized as a qualified supplier by the China Academy of Launch Vehicle Technology is precisely because our Constant Load models meet the stringent standards of extreme precision and reliability demanded by these high-stakes fields.

- Q4: If my Constant Load CNC Band Sawing Machine fails to maintain a constant load, what should I check?

A4: If the load becomes unstable, you should troubleshoot in the following order:

- Load Sensors: Check if the sensor surface is covered with chips or oil, which affects signal reading.

- CNC Parameters: Check if the set target load value is appropriate and if the CNC system's calibration parameters are correct.

- Servo System: Check if the feed servo drive and motor are functioning correctly to ensure they can execute the speed adjustment commands from the CNC quickly and accurately.

Zhejiang SINAIDA Machine Tools Co., Ltd. is a professional manufacturer with well-equipped facilities; we recommend contacting our professional technical team, who can provide precise diagnosis and maintenance guidance.