Advanced Technologies in Angle Sawing Machine for Precision Cutting

Angle sawing machines are designed to provide precise and consistent cuts across a wide range of materials, including ferrous metals, non-ferrous metals, plastics, and composites. At Zhejiang Sinaida Machine Tools Co., Ltd., our CNC band saw machines are engineered to maintain high cutting accuracy even in high-volume operations. The precision of our angle sawing machines is achieved through the integration of mechanical design, cutting technology, and software control systems. Unlike conventional sawing methods, our machines are capable of maintaining exact angles and dimensions over thousands of repetitive operations, ensuring uniformity in production processes. Our focus on high precision allows manufacturers to meet tight tolerances and maintain material integrity without the need for additional post-processing. Beyond accuracy, our machines are optimized for efficiency, reducing cycle times while maintaining superior cut quality. The mechanical components, such as guide rails, saw frames, and blade tensioning systems, are constructed using high-strength alloys to reduce vibration and improve stability during cutting. At Zhejiang Sinaida Machine Tools Co., Ltd., our team of engineers continuously refines these components, implementing design improvements that enhance durability and cutting performance. Our machines integrate control systems that allow operators to monitor cutting parameters in real time. This ensures adjustments can be made to accommodate material variations, optimize feed rates, and achieve consistent results. The combination of mechanical precision, software intelligence, and material adaptability positions our angle sawing machines as a reliable solution for industries requiring precise cutting, such as automotive, aerospace, and metal fabrication. By focusing on the integration of these technologies, Zhejiang Sinaida Machine Tools Co., Ltd. provides manufacturers with tools that maximize productivity, minimize material waste, and enhance overall product quality.

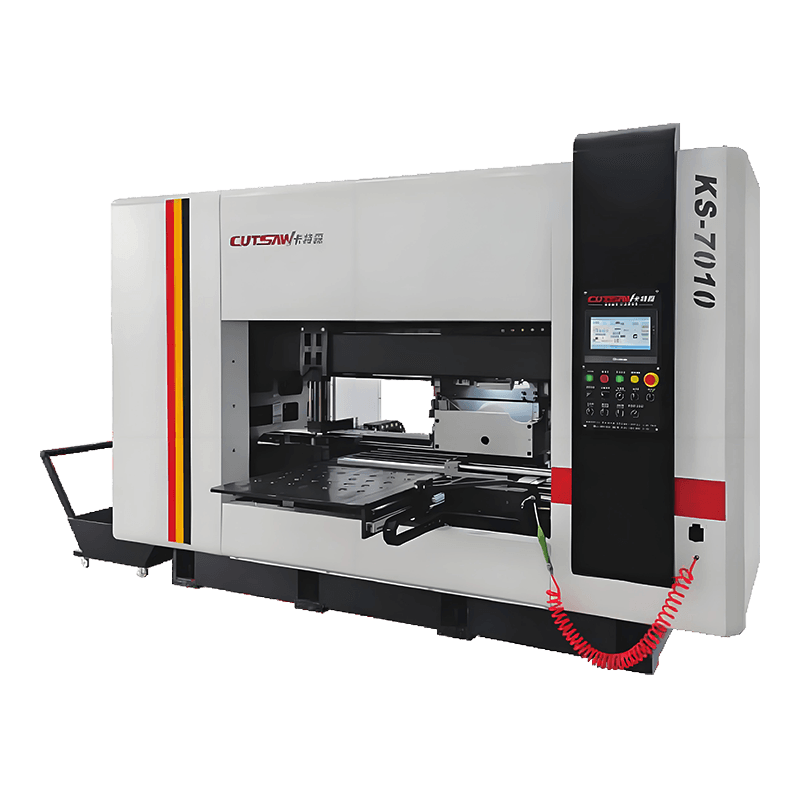

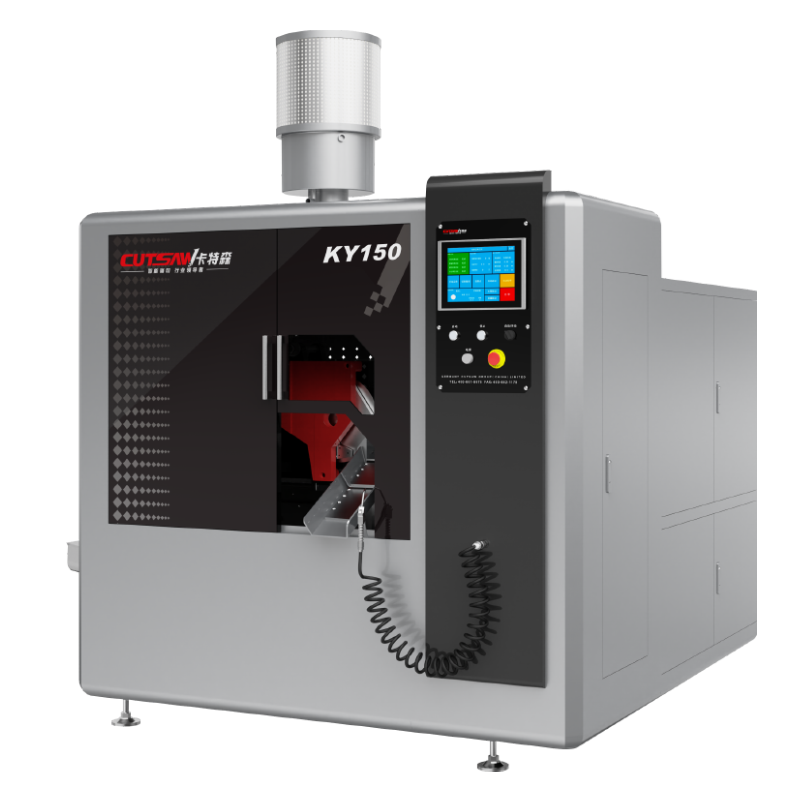

CNC (Computer Numerical Control) technology forms the backbone of modern angle sawing machines. At Zhejiang Sinaida Machine Tools Co., Ltd., our CNC systems allow precise programming of cutting angles, blade speed, feed rate, and cutting depth. This level of control ensures that our angle sawing machines deliver consistent results, reducing material waste and improving throughput efficiency. The CNC system in our machines provides the flexibility to adjust cutting parameters according to material type and thickness, enabling seamless operation across a variety of metals, plastics, and composites. In addition to flexibility, CNC integration supports repeatable cuts, which is essential for batch production where multiple identical components are required. Zhejiang Sinaida Machine Tools Co., Ltd. has developed proprietary software interfaces that simplify programming, allowing operators to input cutting specifications without requiring advanced programming skills. The software includes simulation features that enable virtual testing of cutting paths before actual operation, minimizing the risk of errors and reducing setup time. The CNC system also provides real-time monitoring of cutting forces, blade tension, and operational parameters, ensuring that our machines maintain optimal cutting performance under varying load conditions. This level of monitoring allows our maintenance teams to anticipate wear and adjust parameters proactively, extending the life of both blades and mechanical components. Furthermore, CNC technology supports integration with automated material handling systems. Zhejiang Sinaida Machine Tools Co., Ltd. designs our machines to interface seamlessly with robotic loaders and unloading systems, creating a fully automated workflow for industrial production. This reduces manual handling, improves safety, and ensures consistent throughput. Overall, CNC technology empowers our angle sawing machines with unparalleled precision, repeatability, and adaptability, making us a preferred choice for industries requiring reliable and high-performance cutting solutions.

Automation is a defining feature of modern angle sawing machines. At Zhejiang Sinaida Machine Tools Co., Ltd., we have incorporated advanced automation features into our machines to streamline material handling, optimize cutting efficiency, and reduce operator workload. Automatic feeding systems are a core component of our machines. These systems transport materials into the cutting area with precise positioning, maintaining alignment and reducing the risk of blade deflection. Our automated positioning mechanisms adjust the material angle, feed speed, and blade pressure dynamically, ensuring optimal cutting performance across diverse materials. The integration of automation also includes self-regulating mechanisms that monitor cutting parameters in real time. Our machines can automatically adjust blade speed, feed rate, and pressure depending on the hardness, thickness, or density of the material. This adaptability minimizes material waste, improves blade longevity, and maintains consistent cut quality. At Zhejiang Sinaida Machine Tools Co., Ltd., we have also focused on operator-friendly automation. Our machines feature intuitive touch-screen interfaces that allow operators to select pre-programmed cutting routines or customize new routines for specific requirements. Once a program is selected, the machine executes the cut automatically, eliminating variability caused by human factors. Additionally, our automation extends to post-cut handling. Some models include automatic unloading systems that remove cut pieces and prepare the next material, enabling continuous production cycles without manual intervention. By combining precision mechanical engineering with intelligent automation, Zhejiang Sinaida Machine Tools Co., Ltd. ensures that our angle sawing machines deliver high-quality cuts with minimal operator involvement. The result is a safer, faster, and more productive cutting process, particularly valuable for high-volume industrial operations where efficiency and consistency are essential.

One of the key aspects that sets our angle sawing machines apart is their ability to handle a wide variety of materials with precision. At Zhejiang Sinaida Machine Tools Co., Ltd., we recognize that different materials pose unique challenges in terms of cutting characteristics, such as hardness, flexibility, and heat conductivity. That’s why our angle sawing machines are equipped with features specifically designed to optimize cutting performance across different material types, including ferrous metals, non-ferrous metals, plastics, and composites.

When it comes to ferrous metals like steel, iron, and alloys, our angle sawing machines are engineered to handle the toughness of these materials. Our machines utilize high-speed cutting technology paired with robust saw blades to ensure smooth, clean cuts. The machines also feature adaptive blade tensioning and pressure systems that adjust automatically based on the density and thickness of the material. For example, when cutting through hard steels, our machines adjust the feed rate and blade speed to prevent excessive wear on the blades, maintaining the integrity of the cut without compromising the blade’s life cycle. These features significantly reduce the frequency of blade replacements and lower operational costs.

Non-ferrous metals such as aluminum, copper, brass, and titanium present different cutting challenges due to their lower melting points and softer structures compared to ferrous materials. Our angle sawing machines are designed to accommodate these characteristics by using specially coated blades and variable cutting speeds to reduce friction and prevent material deformation. For instance, when cutting aluminum, our machines automatically adjust the speed and pressure to prevent the material from sticking to the blade, ensuring smooth and precise cuts. For materials like copper and brass, our machines include built-in cooling systems that help to dissipate heat and minimize material distortion.

Plastics and composites often require different cutting strategies, such as slower feed rates and cooler cutting conditions, to prevent material distortion or melting. Our angle sawing machines are equipped with temperature control mechanisms that keep cutting areas cool while maintaining the correct pressure for a clean cut. For example, when cutting thermoplastic materials like PVC or ABS, our systems reduce feed speeds and maintain lower blade temperatures, preventing the material from softening or warping. Our machines are optimized for cutting composite materials, such as fiberglass and carbon fiber, which require precise blade control to avoid fraying and to maintain the structural integrity of the material.

Through these material-specific cutting features, Zhejiang Sinaida Machine Tools Co., Ltd. ensures that our angle sawing machines deliver high-quality cuts, regardless of material type. The ability to seamlessly switch between materials without sacrificing performance gives us a significant edge in industries where versatility is key, such as automotive manufacturing, aerospace, and plastics processing.

In our quest for precision and efficiency, Zhejiang Sinaida Machine Tools Co., Ltd. integrates laser and sensor technologies into our angle sawing machines to ensure cutting accuracy. These advanced technologies play a pivotal role in real-time monitoring and control, enabling our machines to adjust dynamically during the cutting process and maintain high precision throughout the operation.

Laser technology is a fundamental part of our angle sawing machines. These systems continuously measure the cutting path in real time, providing instant feedback on any deviation from the programmed parameters. The laser measurement system ensures that the material is positioned correctly and that the cutting angles remain within tolerance throughout the operation. By using laser-based sensors, we can detect minute changes in material thickness or misalignment, which allows our machines to automatically adjust feed rates and cutting pressures to ensure a flawless cut. This real-time adjustment capability significantly reduces the likelihood of errors and waste, which is particularly important in industries that require strict tolerances, such as aerospace or medical device manufacturing.

In addition to laser measurement, our angle sawing machines are equipped with sophisticated sensors that monitor the thickness of the material being cut, as well as the position and tension of the saw blade. These sensors allow the machine to adapt its cutting parameters dynamically based on the real-time data provided. For instance, if the thickness of the material varies during the cut, the sensors alert the control system, which then adjusts the cutting speed and pressure to maintain a consistent cut. This technology helps us achieve superior cut quality, reduces tool wear, and extends the life of both the blade and the machine. These sensors also monitor the blade’s position and detect any deflection or misalignment, ensuring the cutting path remains true to the programmed trajectory. This is especially important when making precision cuts on large or complex parts, where even a small deviation can lead to significant errors.

The integration of laser and sensor technologies into our machines demonstrates Zhejiang Sinaida Machine Tools Co., Ltd.'s commitment to providing advanced cutting solutions. These technologies not only improve the accuracy of each cut but also provide operators with detailed insights into the cutting process, empowering them to make real-time adjustments and ensure high-quality results.