The rapid evolution of manufacturing technology has introduced numerous tools designed to increase precision, efficiency, and versatility. Among the most significant advancements are precision cutting machines and electric band saw machines. These innovations are essential in various industries such as automotive, aerospace, woodworking, and food processing. Leading companies like Zhejiang Sinaida Machine Tools Co., Ltd. are at the forefront of these advancements, providing high-quality machinery that meets the ever-growing demands of modern manufacturing.

1. The Rise of Precision Cutting Machines in Modern Manufacturing

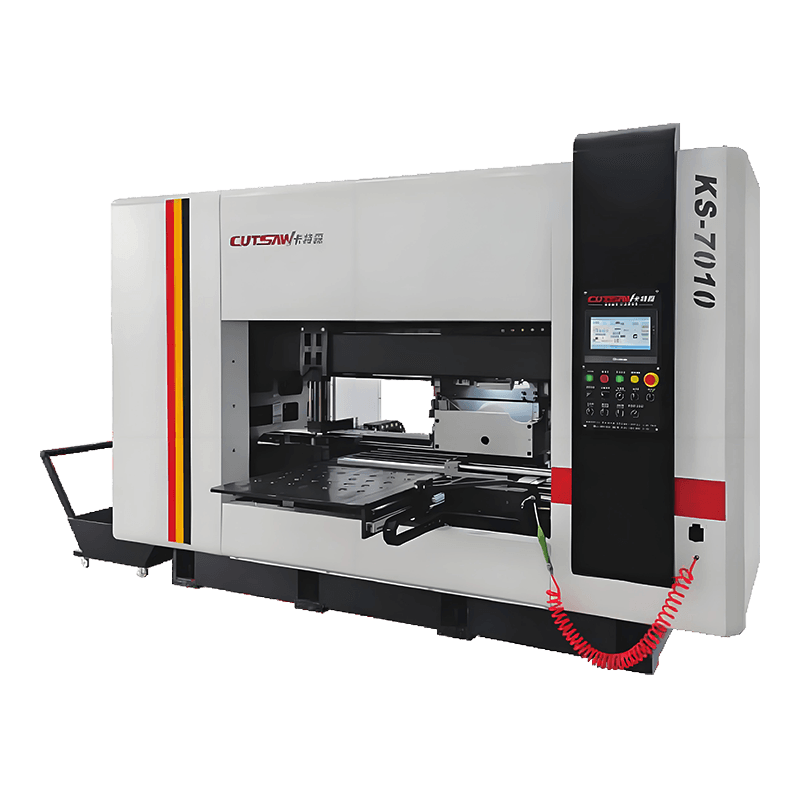

Precision cutting machines are highly specialized tools designed for cutting materials with extreme accuracy. In industries where exact measurements and tight tolerances are crucial, such as aerospace, electronics, and medical devices, precision cutting machines are indispensable. Zhejiang Sinaida Machine Tools Co., Ltd., a global leader in machine tool manufacturing, has developed a wide range of precision cutting solutions that cater to the specific needs of these demanding industries.

Key Features of Precision Cutting Machines:

-

High Accuracy and Tolerances: The most critical feature of precision cutting machines is their ability to execute cuts with micron-level precision. This capability is vital in industries like aerospace, where components must meet exact specifications to ensure performance and safety. Zhejiang Sinaida Machine Tools Co., Ltd. ensures that its precision cutting machines are built with state-of-the-art controls and systems that guarantee unmatched accuracy in every cut.

-

Advanced Automation: Many precision cutting machines are equipped with automated systems, allowing manufacturers to achieve consistent, high-quality cuts with minimal manual intervention. Automation reduces human error, enhances productivity, and allows companies to scale production without compromising quality. Sinaida Machine Tools integrates the latest automation technologies into its machines, enabling manufacturers to streamline operations and maximize efficiency.

-

Material Versatility: Precision cutting machines can process a broad range of materials, including metals, plastics, ceramics, and composites. This makes them highly adaptable to industries that work with various raw materials. Zhejiang Sinaida Machine Tools Co., Ltd. offers customizable machines that can handle multiple material types, catering to sectors like automotive manufacturing, electronics, and medical equipment production.

-

High-Speed Performance: These machines are engineered for high-speed operations, enabling manufacturers to cut faster without sacrificing quality. Zhejiang Sinaida Machine Tools Co., Ltd. prioritizes the optimization of machine speeds, reducing cycle time and increasing overall productivity.

Benefits:

-

Increased Productivity: The automation and high-speed capabilities of precision cutting machines allow manufacturers to produce more components in less time. This results in higher throughput and better utilization of resources, making production lines more efficient.

-

Enhanced Consistency: Precision cutting machines provide uniformity in the final product. The repeatability of the cuts ensures that every item produced meets the same high standards, which is especially important in industries where consistency is paramount, such as the medical or electronics sectors.

-

Reduced Material Waste: Precision cutting reduces the amount of scrap material generated during the cutting process. By ensuring that cuts are accurate, manufacturers can make the most out of their raw materials, lowering costs and contributing to sustainability goals.

Applications:

-

Aerospace Manufacturing: Precision cutting is crucial in the aerospace industry, where parts like turbine blades, fuselage components, and engine parts must be made to stringent tolerances. Zhejiang Sinaida Machine Tools Co., Ltd. provides specialized precision cutting solutions that meet these high demands.

-

Medical Device Production: In the medical industry, precision cutting is essential for creating complex, small-scale parts like surgical instruments and implants. With precision cutting machines from Sinaida, manufacturers can produce these delicate components with the utmost accuracy and quality.

-

Electronics Industry: Printed circuit boards (PCBs) and other small electronic components require highly accurate cutting to fit within tight spaces. Precision cutting machines enable manufacturers to create intricate cuts without damaging sensitive materials.

2. Electric Band Saw Machines: Cutting Efficiency and Versatility

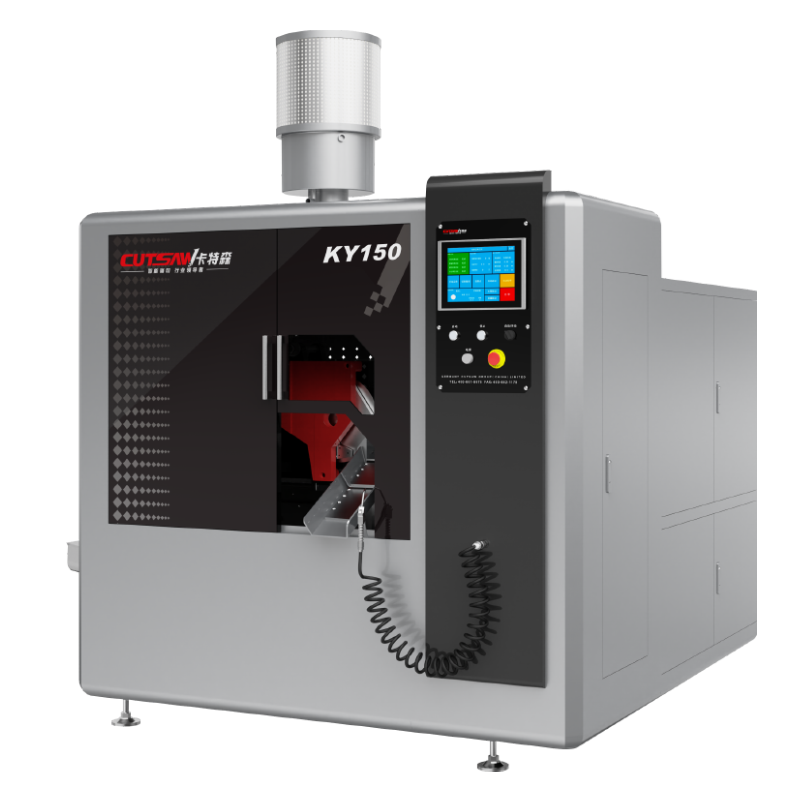

Electric band saw machines are a staple in both metalworking and woodworking industries, valued for their cutting efficiency and adaptability. These machines are designed to cut through a variety of materials, ranging from metals to wood, and can handle both straight and curved cuts. Zhejiang Sinaida Machine Tools Co., Ltd. manufactures electric band saw machines that deliver unmatched versatility and precision in a wide range of industrial applications.

Key Features of Electric Band Saw Machines:

-

Continuous Band Blade: Unlike traditional circular saws, electric band saw machines use a continuous loop of metal band blades. This design allows for smoother, faster cuts with less vibration. Sinaida ensures that its electric band saw machines are built with high-quality band blades that maintain their sharpness and durability over time.

-

Adjustable Blade Speed: One of the significant advantages of electric band saws is the ability to adjust blade speed based on the material being cut. Whether you are working with softwood, hardwood, or metal, an adjustable speed feature ensures optimal cutting conditions. Zhejiang Sinaida Machine Tools Co., Ltd. offers machines that allow for easy speed adjustments, ensuring maximum efficiency across different materials.

-

Variable Cutting Capacity: Electric band saws come in various models with different cutting capacities. Larger machines are designed for heavy-duty operations, capable of cutting through thick metal sections or large wooden beams. Smaller machines are ideal for precision cutting in small-scale applications, such as furniture making or detailed metalwork.

-

High Durability and Safety: The robustness of electric band saws ensures they can handle heavy-duty cutting tasks without compromising performance. Additionally, safety features such as blade guards, emergency stops, and overload protection are incorporated into Zhejiang Sinaida’s machines to ensure safe operation in industrial environments.

Benefits:

-

High Cutting Efficiency: The continuous band blade allows for faster and more efficient cutting compared to traditional methods. This results in reduced cutting time and lower operational costs, benefiting industries like construction and manufacturing.

-

Cost-Effectiveness: Electric band saw machines are generally more economical to operate than other types of cutting equipment. They consume less energy, have lower maintenance costs, and offer a longer lifespan, which translates to lower total operating costs for manufacturers.

-

Flexibility: With their ability to cut a wide range of materials, electric band saws are incredibly versatile. Whether cutting through metal, plastic, or wood, Zhejiang Sinaida Machine Tools Co., Ltd. ensures that its electric band saws can handle various applications in different industries.

Applications:

-

Metalworking: In the metalworking industry, electric band saws are essential for cutting through large metal sections, pipes, and beams. They are widely used in industries such as automotive manufacturing, construction, and shipbuilding.

-

Woodworking: In woodworking, electric band saws are used for cutting timber into planks, beams, and intricate shapes. They are favored by carpenters and furniture manufacturers for their ability to cut both straight and curved lines with precision.

-

Food Processing: In the food industry, electric band saws are used to cut large pieces of meat, fish, or frozen products. These machines are designed to operate in hygienic conditions and maintain cutting efficiency, making them essential in modern food processing plants.

Comparison of Precision Cutting Machines vs Electric Band Saw Machines

| Feature |

Precision Cutting Machines |

Electric Band Saw Machines |

| Cutting Material |

Metals, Plastics, Ceramics, Composites |

Metals, Wood, Plastics, Food Products |

| Cutting Accuracy |

Micron-level precision |

Moderate to High, with adjustable precision |

| Speed |

High-speed, with automated control systems |

Moderate to High, with variable speed options |

| Applications |

Aerospace, Electronics, Medical Devices |

Metalworking, Woodworking, Food Processing |

| Automation |

Fully automated, minimal manual intervention |

Mostly manual, some models offer automation |

| Cost |

Higher initial investment, lower operating cost |

Lower initial investment, moderate operating cost |

3. Applications and Industry Integration

Both precision cutting machines and electric band saw machines are indispensable in modern manufacturing due to their efficiency, versatility, and precision. Industries that rely on high-quality production and need to meet stringent standards have integrated these machines into their operations to stay competitive in the market. Zhejiang Sinaida Machine Tools Co., Ltd. plays a pivotal role in this process by offering cutting-edge machines that cater to various industrial needs, from large-scale manufacturing to specialized small-scale operations.

Precision Cutting Machines in Industry:

-

Aerospace and Defense: Aerospace components must meet very specific tolerances to ensure safety and functionality. Zhejiang Sinaida Machine Tools Co., Ltd. provides advanced precision cutting solutions that help manufacturers in this sector create highly complex parts with micron-level precision.

-

Medical Devices: The medical industry requires precision components that meet strict regulatory standards. Precision cutting machines are used to create implants, surgical tools, and diagnostic devices with incredible accuracy, ensuring patient safety and reliability.

-

Electronics Manufacturing: Precision cutting is vital in the production of small electronic components, where even minor deviations can lead to malfunctions. Sinaida supplies cutting-edge equipment that helps manufacturers in the electronics industry achieve consistent, high-quality results.

Electric Band Saw Machines in Industry:

-

Metalworking: Electric band saw machines are widely used in metalworking for cutting through large metal sections and beams, which are essential in industries like construction, automotive manufacturing, and shipbuilding.

-

Woodworking: In woodworking, these machines are used for creating precise cuts in wooden planks and beams, and are an essential tool for furniture manufacturers and carpenters who need high-quality cuts in wood.

-

Food Processing: Band saws are also used in the food industry, such as cutting large pieces of meat or frozen products, allowing for efficiency and hygiene in production.