What Mechanical and Operational Advantages Make Vertical Band Sawing Machines Indispensable for Large-Format and Contour Cutting?

The Vertical Band Sawing Machine occupies a unique and indispensable position within the metal cutting and fabrication industry, offering distinct mechanical and operational advantages that horizontal counterparts cannot match. Unlike horizontal saws, where the blade moves vertically through a clamped, stationary workpiece, the Vertical Band Sawing Machine features a vertically oriented blade that passes through a stationary or precisely controlled moving table. This design pivot fundamentally redefines the machine's utility, making it the primary choice for complex contouring, cutting irregular shapes, and managing exceptionally large or heavy plate materials.

The Foundation of Versatility: Design and Capacity

The intrinsic design of a Vertical Band Saw allows for unmatched versatility. Firstly, the unlimited cutting length capability is a major differentiator. Since the material is fed across a table, there is no physical limitation on the length of the stock that can be processed. This is crucial for applications involving extended structural beams, long plates, or oversized material sheets common in shipbuilding and large-scale infrastructure projects.

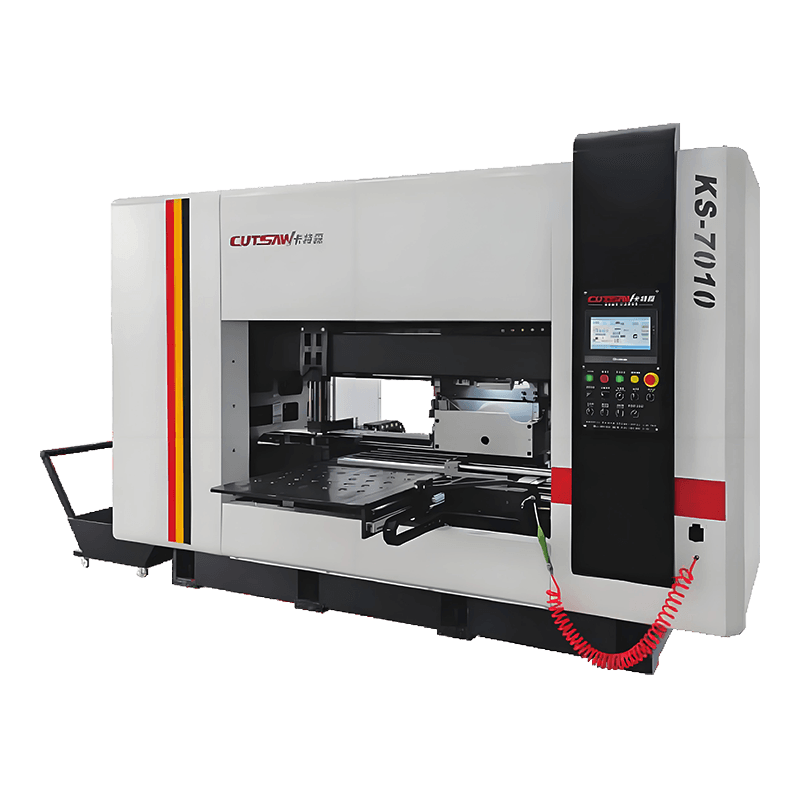

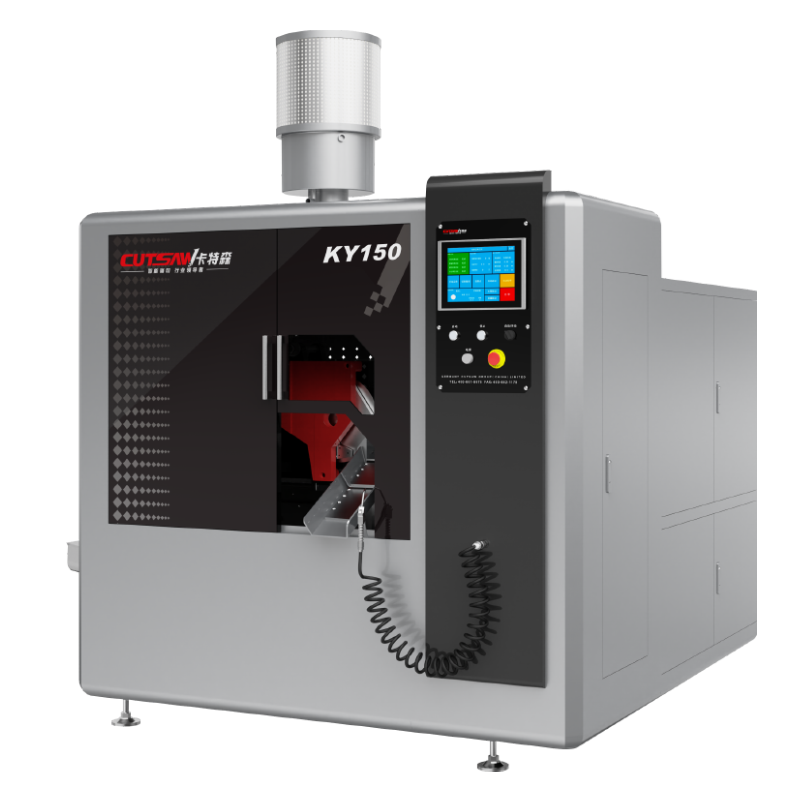

Secondly, the Vertical Band Sawing Machine's throat size becomes the limiting factor, which can be custom-engineered to enormous dimensions. The "throat" is the distance from the blade to the back column of the machine. Manufacturers like Zhejiang Sinaida Machine Tools Co., Ltd., a CNC band saw machine manufacturer, specialize in offering extra-large customized models that meet this demand for vast throat clearances, allowing them to cut large-format die blocks, molds, and massive structural components that simply cannot be accommodated by standard horizontal machines.

Thirdly, the vertically oriented blade allows the operator to visually follow the cut line, especially in manual or semi-automatic Vertical Band Sawing Machines, which is essential for accurate contour cutting or separating large blanks from plate stock based on a layout line. The ability to rotate the material on the table, often utilizing a dedicated rotary axis or precise feed mechanisms, enables the execution of internal and external radii, slots, notches, and complex geometric shapes required in tool and die making.

Enhancing Precision and Rigidity for Complex Loads

To ensure that the inherent versatility does not compromise accuracy, high-end Vertical Band Sawing Machines must be built with exceptional rigidity. SINAIDA’s status as a national high-tech enterprise and its commitment to advanced production technology are critical here. The machine frame, particularly the backbone supporting the wheel and blade guides, must possess superior mechanical strength and minimal deflection. When cutting heavy die steel blocks or thick titanium plates, the pressure exerted on the blade and machine components is immense.

The stability of the cutting process is managed through:

Heavy-Duty, Stress-Relieved Frames: The use of heavy, stress-relieved steel for the main chassis minimizes operational vibration and thermal distortion, which is essential for maintaining micron-level cutting precision across large cutting areas.

Precision Roller Guides: The blade guides, which stabilize the cutting tool immediately above and below the workpiece, are precision-engineered to prevent twisting or lateral movement of the blade. This is paramount for achieving the smooth, perpendicular surface finish necessary for quality fabrication.

Variable Speed Drive Systems: The ability to precisely control the blade's surface speed is vital for material compatibility. Hardened tool steels require much lower speeds to manage heat and wear, while non-ferrous materials like aluminum or specialized plastics demand much higher speeds. Advanced Vertical Band Sawing Machines feature wide-ranging variable frequency drives that allow the operator to fine-tune the SFM, protecting the blade and optimizing the cut quality for the cutting ferrous and non-ferrous metals, plastics, and other non-metallic materials.

The operational modes of the Vertical Band Sawing Machine, ranging from simple vertical separation to highly specialized contour cuts, make it indispensable for job shops that handle diverse tasks. Its capacity to handle odd-shaped pieces, large plates, and heavy blocks distinguishes it as a flexible, heavy-duty processing tool, supported by the strong technical capabilities of leading manufacturers.

How Do Advanced CNC Systems and Stringent Quality Standards Elevate Vertical Band Saw Technology for High-Demand Industries?

The transition of the Vertical Band Sawing Machine from a manually operated tool to a sophisticated CNC system represents the single largest leap in its capability, moving it from the prototyping shop floor to the high-volume, high-precision world of modern aerospace and structural manufacturing. The integration of CNC systems is what allows Vertical Band Sawing Machines to uphold the stringent quality standards demanded by high-demand sectors.

CNC Integration for Unprecedented Automation and Complexity:

Modern Vertical Band Sawing Machines are integrated with highly advanced Computer Numerical Control (CNC) systems that manage multiple axes of motion simultaneously. While the blade itself moves only along the Z-axis (downfeed), the cutting path is controlled by highly precise movement of the worktable (X and Y axes).

Automated Contour Programming: CNC Vertical Band Sawing Machines enable the creation and execution of complex, nested cutting programs. This means an operator can load a large plate and the machine can automatically cut dozens of unique, intricate parts without human intervention, maximizing material yield and ensuring dimensional accuracy. This capability for high-precision CNC sawing is essential for industries where complex geometries are the norm.

Adaptive Feed Control: The CNC system constantly monitors the cutting load and adjusts the table feed rate and blade downfeed pressure in real time. For instance, when the blade enters a thicker or harder section of the material, the system will momentarily slow the feed rate to prevent blade stalling or breakage. This level of control, a hallmark of advanced production technology, dramatically extends blade life and maintains consistent surface finish across varied material cross-sections.

Four-Axis Miter/Notch Capability: While traditionally known for straight and contour cuts, modern CNC Vertical Band Sawing Machines can integrate with rotary tables to perform precise angular cuts, notching, and pipe profiling, expanding their utility into structural and tube fabrication where precision fit-up is mandatory.

Upholding Aerospace Quality and Technical Capability:

The application of Vertical Band Sawing Machine technology in the aerospace industry sets the highest bar for quality and reliability. The fact that SINAIDA CNC sawing machines support China’s aerospace industry and the company is recognized as a qualified supplier by the China Academy of Launch Vehicle Technology is a powerful testament to the precision of their manufacturing processes. Aerospace components, whether structural aluminum wing spars or high-temperature nickel alloy engine mounts, require cuts that meet exacting specifications to ensure material integrity and structural compliance.

This level of performance is achieved through a combination of institutional expertise and certified manufacturing practice:

Strong Technical and R&D Teams: Sustained precision in high-output machines is a function of continuous research and development. Manufacturers with strong technical capabilities, like SINAIDA, invest heavily in materials science, motion control systems, and proprietary software to push the boundaries of accuracy, ensuring their equipment can handle new exotic alloys and stricter tolerance requirements.

Annual Capacity and Customization: With an annual production capacity of 3,600 units, SINAIDA demonstrates the scalability and reliability of its manufacturing process. Furthermore, the ability to undertake the design and production of extra-large customized models allows them to directly address niche demands, such as specialty tooling for large aircraft assemblies or defense-related manufacturing.

Optimizing Blade Life and Maintenance Efficiency:

The long-term economic viability of a Vertical Band Sawing Machine hinges on minimizing recurring costs, primarily blade replacement and maintenance downtime. Leading manufacturers integrate sophisticated diagnostics and smart operational features to enhance maintenance efficiency and extend the life of consumables. SINAIDA’s expertise in high-tech manufacturing ensures these features are robust and reliable.

Automated Blade Monitoring and Diagnostics: High-end Vertical Band Sawing Machines employ sensors to continuously track critical operational parameters. This includes monitoring blade tension, blade tracking stability, and vibration levels. If the tension drops below the optimal threshold, the machine alerts the operator or automatically adjusts it. This proactive system prevents common issues like premature blade fatigue and inconsistent cut quality, ensuring optimal performance from the high-precision CNC sawing process.

User-Friendly Diagnostic Interfaces: Modern CNC controls feature intuitive human-machine interfaces (HMIs) that provide real-time status updates and predictive maintenance alerts. These systems can estimate remaining blade life based on cutting load history and material type, allowing the operator to schedule replacement before a failure occurs. This dramatically reduces unplanned downtime, enhancing overall equipment effectiveness.

Modular Component Design: For unavoidable maintenance, the machine structure is designed with modularity in mind. Key wear components, such as the blade guides, chip conveyors, and hydraulic pump assemblies, are engineered for quick removal and replacement. This design philosophy minimizes the machine's time out of service, a critical consideration for maintaining high throughput in plants utilizing extra-large customized models for continuous production. The integration of advanced filtration and chip evacuation systems further contributes to low-maintenance operation by keeping the coolant and work area clean.

In essence, the modern Vertical Band Sawing Machine is a nexus of mechanical strength, adaptive automation, and certified quality. Its role in processing complex geometries and handling large-scale materials, backed by the expertise and advanced production technology of companies like SINAIDA, solidifies its critical importance in today's high-tech manufacturing landscape.

|

Feature

|

Vertical Band Sawing Machine

|

Horizontal Band Sawing Machine (HSM)

|

|

Workpiece Motion

|

Stationary or moved via dedicated CNC table.

|

Fed horizontally into the blade.

|

|

Primary Function

|

Contour cutting, cutting large plates, complex shapes, notching, angular cuts.

|

Production cutting, slicing bar stock, straight cuts, high throughput.

|

|

Material Size

|

Unlimited length; limited by throat depth.

|

Limited by clamping vice width and height.

|

|

Blade Orientation

|

Vertical, allows operator interaction and following a layout line.

|

Horizontal, minimizes floor space for production runs.

|

|

Cutting Force

|

Generally lower, focused on precision and minimal material stress.

|

Higher, focused on rapid material removal and production rate.

|

This complete overview demonstrates the sophisticated capabilities and strategic importance of Vertical Band Sawing Machines, driven by the technical excellence of leading manufacturers.