CNC Sawing Machine Technical Capabilities and Features

At SINAIDA, our

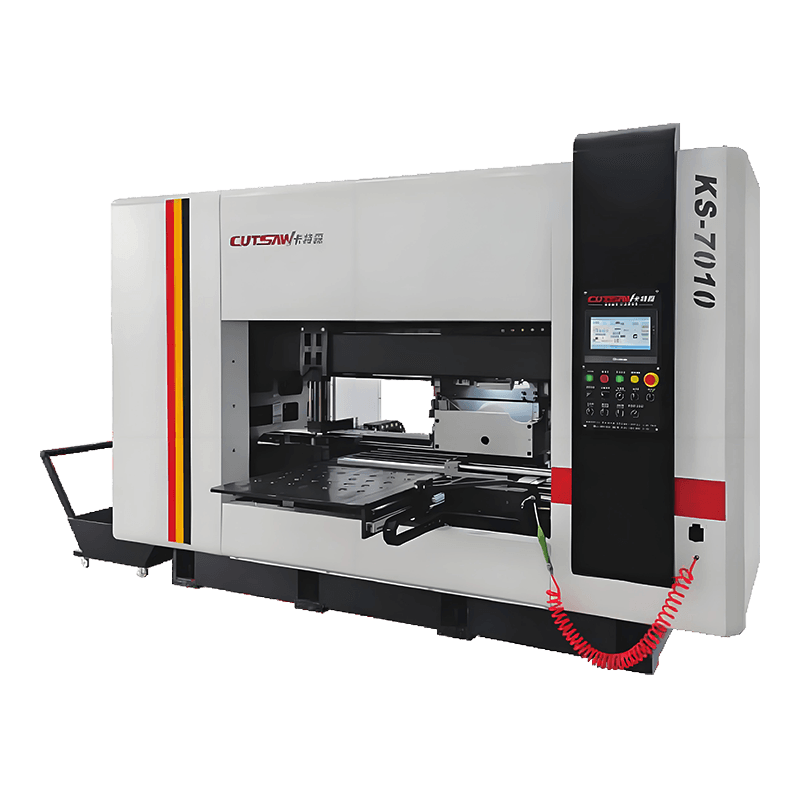

CNC sawing machines are powered by cutting-edge CNC control systems designed to deliver high precision and efficiency. Our machines are equipped with user-friendly interfaces that make it easy for operators to set up complex cutting operations. The control systems can be programmed with a wide range of cutting parameters such as speed, feed rate, and depth of cut, enabling us to achieve optimal cutting results across a wide variety of materials. We have designed our CNC control systems to be highly flexible, allowing manufacturers to switch between different cutting programs with minimal setup time, reducing downtime and increasing production efficiency. The control systems in our machines offer advanced features like real-time cutting parameter monitoring and automatic adjustments. This ensures that the cutting process remains stable even when there are fluctuations in material properties or environmental conditions. The machines can make real-time adjustments to cutting speed and feed rates, reducing the risk of material damage or tool wear. By incorporating feedback loops from sensors, the CNC system can also adjust to any unexpected variances in the material, such as thickness variations, to ensure consistency in each cut. SINAIDA’s CNC systems also provide remote diagnostics and real-time performance monitoring. With this feature, operators and managers can check the status of the machine remotely and make adjustments as necessary without being physically present on the shop floor. This capability is particularly useful in large-scale production environments where multiple machines are in operation. With the ability to store multiple cutting programs, we enable our users to switch between production runs without the need to reprogram the machine, improving overall efficiency and consistency.

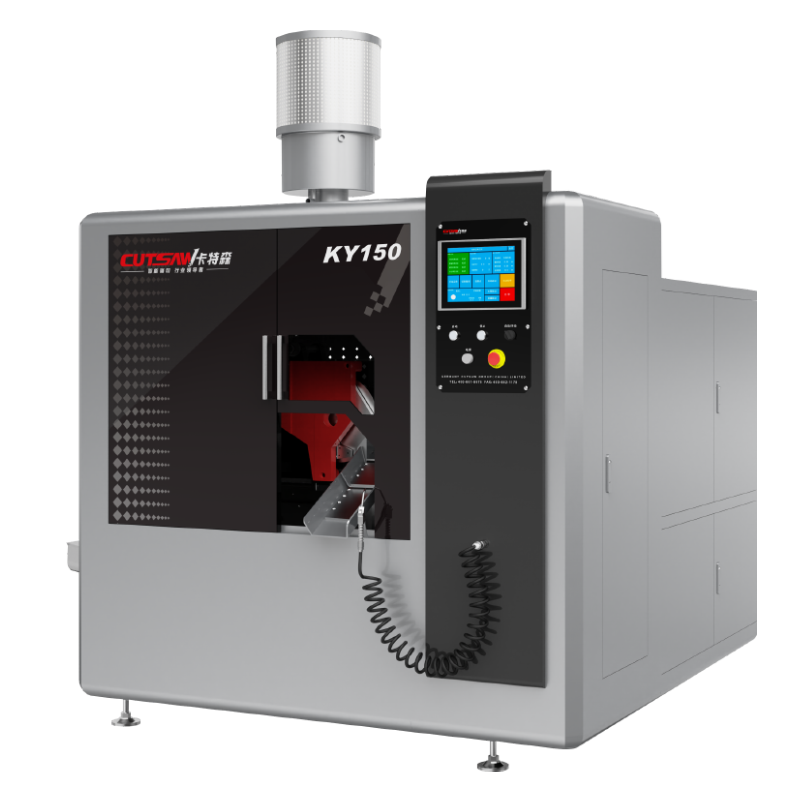

The precision of a CNC sawing machine largely depends on the blade guidance system and its ability to maintain stability during high-speed cutting operations. At SINAIDA, we have integrated high-precision blade guidance systems that ensure consistent alignment throughout the cutting process. These systems include advanced linear guides and reinforced blade holders that work together to minimize blade deflection and ensure that every cut is executed with extreme accuracy. Blade deflection, which can occur when cutting through hard materials, can result in deviations in cut quality, so we have engineered our machines to keep this factor to a minimum. Our CNC sawing machines are also equipped with advanced tensioning systems for band saw blades. Proper tensioning is essential for maintaining the straightness of the cut and minimizing vibrations during operation. SINAIDA's tensioning system allows for precise blade tension adjustments, which are crucial for cutting different material types at varying thicknesses. The integration of high-quality bearings and spindle assemblies ensures smooth, uninterrupted blade movement, contributing to the overall accuracy of each cut. For circular saw models, we have utilized high-rigidity spindles that maintain blade stability even at high rotational speeds. These spindles are supported by advanced bearing systems that minimize runout, which is the wobbling of the blade during rotation. The reduced runout helps ensure that the cuts are accurate and free from defects such as rough edges or uneven surfaces. By optimizing the blade guidance and tensioning systems, we can guarantee that our CNC sawing machines consistently deliver high-quality cuts across a wide range of materials, including ferrous and non-ferrous metals, plastics, and composites.

Servo motor technology plays a critical role in the performance of our CNC sawing machines. At SINAIDA, we utilize high-efficiency servo motors that offer precise control over both the cutting blade and the material feed systems. Servo motors are known for their ability to provide accurate speed and position control, allowing us to maintain a consistent cutting process even under varying load conditions. This technology enables our machines to achieve high-speed, high-precision cuts with minimal energy consumption. The servo motor-driven feed systems in our machines allow for rapid acceleration and deceleration of both the blade and the material. This ability to adjust quickly to changing material conditions is essential for applications that require both high precision and speed. For instance, when cutting through different materials like steel and aluminum, the servo motors adjust the feed rate accordingly to optimize cutting speed and material integrity. The precision of the servo motors also reduces mechanical stress, which in turn reduces wear and tear on the machine’s components. In addition to improving cutting precision, the use of servo motors increases operational efficiency. The motors offer superior responsiveness to changes in material thickness or density, ensuring that we maintain consistent cutting quality even with irregular or difficult materials. Servo-driven machines typically consume less power than traditional mechanical feed systems, making them more energy-efficient and cost-effective in the long run. This combination of precision, speed, and energy efficiency makes our CNC sawing machines ideal for industries that require both high performance and sustainability.

In modern manufacturing, the integration of automated material handling systems with CNC sawing machines is crucial for improving productivity and reducing labor costs. At SINAIDA, we offer CNC sawing machines that can be seamlessly integrated with automated material handling systems, such as motorized infeed and outfeed rollers, hydraulic clamps, and robotic arms. These systems ensure that the material is loaded, positioned, and unloaded with minimal manual intervention, reducing the risk of human error and speeding up the production process. The automation systems in our machines are designed to handle a wide range of materials, from small components to large and heavy workpieces. For instance, in the aerospace industry, where precision and safety are critical, automated material handling ensures that each part is positioned accurately before cutting, reducing the chances of misalignment or material damage. By automating the material feeding process, we also eliminate the variability that can arise from human operators, ensuring that every cut is consistent and precise. Our machines also come equipped with programmable clamps and hold-downs that secure the material during the cutting process. This is especially important for irregularly shaped or flexible materials that may shift or move during cutting. The automated system ensures that the material is securely held in place without causing damage or distortion. Furthermore, we offer fully automated cutting systems that can process multiple pieces of material simultaneously, allowing manufacturers to significantly increase throughput without sacrificing cutting quality.

The ability to select the right blade for each application is critical for achieving optimal cutting performance. At SINAIDA, our CNC sawing machines offer a wide range of blade options to accommodate different materials, thicknesses, and cutting requirements. We provide detailed recommendations for choosing the ideal blade type, tooth geometry, and cutting parameters for specific materials, ensuring that each operation achieves the desired balance of speed, precision, and surface finish. For cutting ferrous metals like steel and iron, we offer high-performance carbide-tipped blades that are durable and resistant to wear. For non-ferrous metals such as aluminum, copper, and brass, we provide high-speed steel blades that maintain sharpness for longer periods. For cutting softer materials like plastics or rubber, we offer blades with specialized teeth and coatings designed to minimize heat buildup and prevent material deformation. Our CNC sawing machines also allow for adjustments to blade speed and feed rates, enabling users to tailor the cutting process based on the material being cut. For example, when cutting thicker or harder materials, we can adjust the speed of the blade to prevent overheating and ensure clean cuts. This versatility allows our machines to handle a wide range of applications, from rough cuts in large metal beams to fine, intricate cuts in delicate materials.

Cutting hard materials generates significant heat, which can lead to tool wear, material deformation, and a decrease in cutting performance. To mitigate these issues, SINAIDA CNC sawing machines are equipped with advanced cooling and lubrication systems that ensure the cutting process remains smooth and efficient. Our machines feature intelligent coolant delivery systems that provide precise amounts of coolant directly to the cutting area, reducing friction and heat buildup. The cooling system is fully programmable, allowing us to adjust the flow rate based on the material being cut and the cutting speed. For instance, when cutting through high-density metals like titanium, the coolant flow can be increased to prevent the material from overheating, ensuring that the cut remains clean and precise. Our intelligent lubrication systems also help extend the life of the blade by reducing friction between the material and the cutting tool, which minimizes wear and tear. SINAIDA’s CNC sawing machines are designed with environmentally friendly features in mind. The cooling and lubrication systems are designed to minimize waste, using closed-loop systems that recycle coolant and reduce the amount of fluid required. This not only reduces environmental impact but also lowers operating costs by minimizing the need for frequent coolant replacements. Our machines are also equipped with filtration systems that ensure coolant remains clean and free from contaminants, further enhancing the efficiency and lifespan of the cutting tools.