What are the fundamental mechanical and kinematic advantages of Metal Circular Sawing Machines over band saws in achieving extreme precision and surface finish?

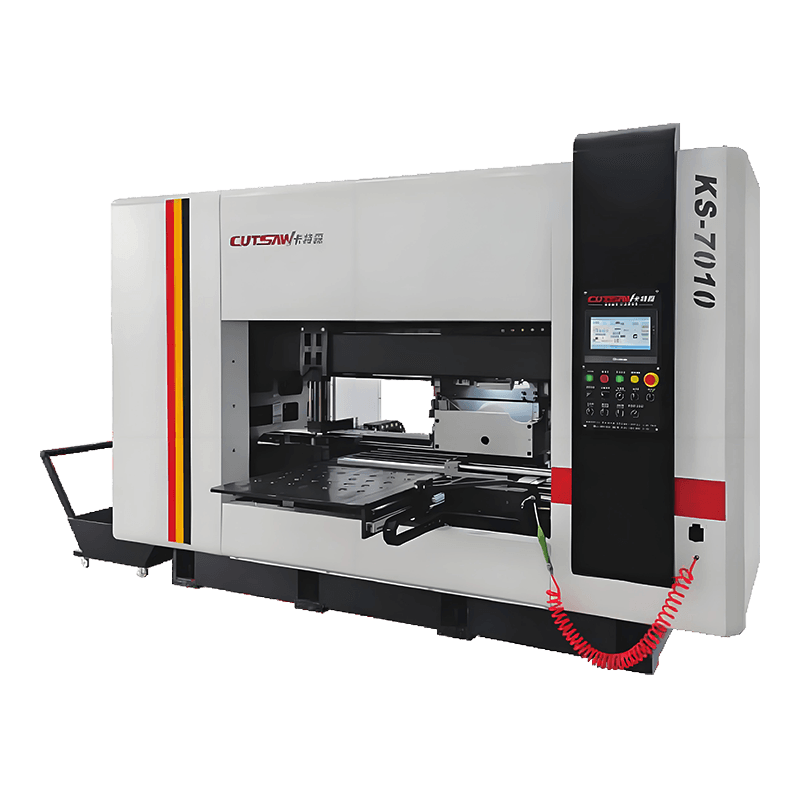

The Metal Circular Sawing Machine is recognized across the global manufacturing landscape as the preeminent tool for achieving cuts of superior accuracy, minimal burr, and exceptional surface finish, particularly when processing solid bars, tubes, and complex profiles. Unlike band saws, which rely on a flexible, linear blade in continuous motion, the circular saw employs a highly rigid, rotary disc blade, often fitted with high-speed steel or carbide tips. This fundamental difference in tooling geometry and cutting kinematics provides inherent mechanical advantages that make it indispensable in sectors demanding zero-tolerance processing.

The Mechanical Superiority of the Rigid Blade:

The principal advantage of the Metal Circular Sawing Machine stems from its rigidity. The saw blade is a solid disc, securely mounted on a robust spindle and driven by a powerful motor. This eliminates the flexibility and tracking deviations inherent in a band saw blade.

Superior Cut Squareness: A rigid circular blade maintains its path integrity through the entire workpiece cross-section. This results in cut faces that are perpendicular to the material axis, often achieving squareness tolerances far tighter than those possible with flexible band blades. This precision minimizes the need for subsequent machining operations like milling or facing, contributing significantly to efficient metal processing.

Reduced Vibration and Flutter: The heavy, damped construction of the circular saw head, combined with the rigidity of the blade itself, drastically reduces vibration and chatter during the cut. Vibration is the primary enemy of surface finish and tool life; by minimizing it, the Metal Circular Sawing Machine delivers a mirror-like finish, often eliminating the need for grinding.

Controlled Chip Formation: Modern Metal Circular Sawing Machines are often referred to as 'Cold Saws' because they manage thermal energy so effectively. They operate with a relatively low peripheral blade speed and a high feed rate, producing distinct, coiled chips that carry heat away from the workpiece and the blade teeth. This mechanism prevents thermal distortion in the material, ensuring the dimensional integrity of the finished part—a crucial requirement when cutting ferrous and non-ferrous metals used in critical applications.

Manufacturers, including Zhejiang Sinaida Machine Tools Co., Ltd. and professional CNC band saw machine manufacturer, utilizing strong technical capabilities and a history of employing advanced production technology, have successfully leveraged their expertise in building highly rigid sawing platforms to optimize circular saw performance. Their focus on the structural integrity of the machine base and the precision of the spindle assembly ensures that the rotary cutting action remains stable even under the highest loads associated with cutting tough, high-tensile alloys. The robust design guarantees the machine’s ability to deliver consistent results over its operational lifespan, meeting the needs of both domestic and international markets.

Kinematic Efficiency and Material Feed:

The cutting action of a Metal Circular Sawing Machine is characterized by a precisely controlled, linear feed. The blade is typically fed horizontally or vertically through the material in a continuous, measured stroke.

Uniform Cutting Force Distribution: Unlike the arcing motion of a pivot-arm saw, the linear feed ensures that the cutting force is distributed predictably. This allows the operator or CNC system to accurately model the forces and set the ideal chip load, maximizing the material removal rate without compromising the tool life.

High Feed Rate Potential: Because the force is concentrated and the blade is rigid, the machine can sustain significantly higher linear feed rates compared to band saws, especially when using high-performance carbide-tipped blades. This results in cycle times that are often dramatically shorter, making it the choice for operations demanding rapid throughput and high-volume production.

Capacity for Miter and Compound Cutting: Many Metal Circular Sawing Machines are equipped with swivel heads or rotating vises, enabling precise angular cuts (miters) without moving the workpiece. The ability to execute these cuts quickly and accurately, often with CNC control, makes them essential for frame, structure, and tube manufacturing. The rigidity ensures that the angle is maintained precisely across the entire cut, a critical factor for subsequent welding fit-up.

This combination of mechanical robustness and optimized kinematics ensures that the Metal Circular Sawing Machine excels where cut quality and speed are paramount. The reliability is further validated by the manufacturer's commitment to quality assurance, having achieved certifications such as ISO9001 quality management system certification, China Machinery Safety Certification, and EU CE certification.

How do integrated CNC controls and specialized tooling systems in modern Circular Saws meet the rigorous demands of aerospace and high-speed production?

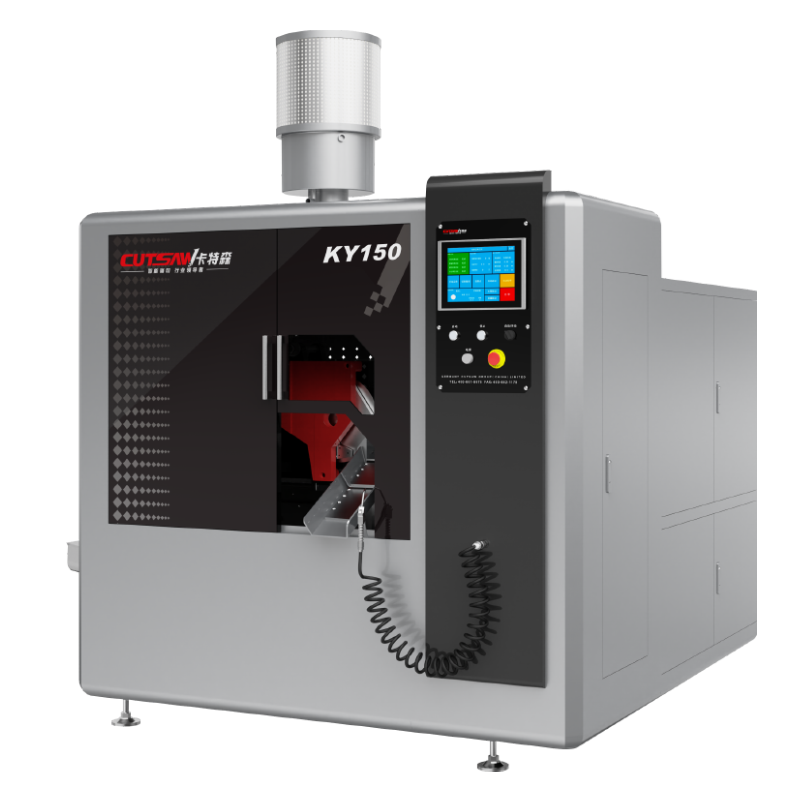

The modern Metal Circular Sawing Machine has transcended its purely mechanical roots through the integration of sophisticated CNC technology, transforming it into a smart, automated cutting cell. This evolution is critical for meeting the stringent quality and efficiency requirements of high-demand industries, particularly aerospace and automotive component manufacturing.

CNC Integration for Unparalleled Accuracy and Automation:

Advanced Computer Numerical Control systems are the core intelligence driving high-performance circular saws. These systems manage not only the blade speed and feed rate but also material handling, clamping, and error compensation.

Servo-Driven Indexing: High-speed production demands repeatable accuracy in part length. Modern CNC Circular Saws use powerful servo motors coupled with ball screws to advance the material precisely. This Automated Material Indexing guarantees length repeatability often better than ≤0.02 mm, minimizing scrap and ensuring conformity for post-cutting processes. This is a core feature of high-precision CNC sawing.

Adaptive Cutting Control: This feature is crucial for protecting expensive carbide blades and ensuring consistent performance across heterogeneous materials. The CNC system continuously monitors the power draw of the main blade motor, which serves as a proxy for the cutting load. If the load deviates outside the pre-set optimal window signaling either premature wear or resistance from an unknown material inclusion the system instantly adjusts the feed rate to maintain the correct chip load per tooth. This capability, enabled by advanced production technology, dramatically extends tool life and maintains cut quality automatically.

Tool Life Management: The CNC system tracks the usage of each blade, calculating its remaining life based on the material cut, cutting time, and accumulated load data. It alerts the operator when a blade change is recommended, preventing catastrophic failures and unscheduled downtime. This type of proactive maintenance is essential for maximizing the operational efficiency of the Metal Circular Sawing Machine.

The ability to maintain this extreme level of precision and consistency is why the machinery produced by qualified manufacturers is trusted in the most sensitive sectors. For example, the CNC sawing machines from this national high-tech enterprise support China’s aerospace industry and the company is recognized as a qualified supplier by the China Academy of Launch Vehicle Technology. This designation confirms that their Metal Circular Sawing Machines are built and tested to meet the rigorous specifications required for processing materials used in high-integrity aerospace components.

Specialized Tooling and Material Versatility:

The performance of a Metal Circular Sawing Machine is highly dependent on its tooling, which is specialized for the material being processed.

Carbide-Tipped Circular Saw : For the fastest and most demanding cuts in ferrous materials, Carbide-Tipped Circular Saw blades are used. These blades allow for extremely high surface feet per minute and aggressive feed rates, delivering unparalleled throughput in automotive shafting, gear blanks, and hydraulic cylinder components. The machine structure must be robust enough to handle the immense forces generated by carbide cutting, a testament to the robust construction for production environments provided by experienced manufacturers.

HSS Blades for Tough Alloys: High-Speed Steel blades remain the preferred choice for cutting materials that require slower speeds, such as stainless steels, tool steels, and exotic nickel alloys common in the aerospace industry. The ability of the Metal Circular Sawing Machine to precisely regulate the blade speed and maintain rigidity at low RPMs is crucial for successfully processing these work-hardening materials.

Non-Ferrous Processing: Specialized aluminum and non-ferrous cutting circular saws operate at extremely high RPMs to achieve a clean, burr-free finish. The versatility of leading manufacturers, which produce machinery used for cutting ferrous and non-ferrous metals, plastics, and other non-metallic materials, ensures that their machine platforms are adaptable to the thermal and kinematic demands of this diverse material portfolio.

With an annual production capacity of 3,600 units, this enterprise demonstrates the scalability of its manufacturing processes, allowing them to support the high-volume needs of global clients. Furthermore, its ability to undertake the design and production of extra-large customized models means they can provide purpose-built circular sawing solutions for unique or massive material processing applications.

The superior mechanical design, integrated high-precision CNC sawing systems, and the backing of strong technical expertise make the Metal Circular Sawing Machine an essential tool in achieving the accuracy, efficiency, and safety standards required by today's most demanding fabrication and manufacturing industries, ensuring consistent output for domestic and international markets.