-

Adjustable Cutting Angles: The Vertical Band Sawing Machine is engineered to accommodate a wide variety of cutting angles, which is critical for producing complex parts and precision components in both industrial and workshop environments. Many models allow the blade or table assembly to tilt or pivot, giving operators the ability to set precise angles for bevel or compound cuts. This adjustability enables the machine to perform cuts that would otherwise require additional jigs or secondary operations, reducing setup time and potential for human error. For industrial users, the ability to quickly adjust cutting angles enhances versatility, allowing the same machine to handle multiple tasks—from structural metal fabrication to intricate woodworking—without the need for multiple specialized cutting tools.

-

Tilting Tables: Tilting tables significantly enhance the operational flexibility of a Vertical Band Sawing Machine. High-quality machines typically feature tables that can tilt from 0° up to 45° or more, enabling precise angled cuts directly on the workpiece. This capability eliminates the need to reposition the material repeatedly, minimizing handling errors and improving workflow efficiency. The tilting table also provides ergonomic advantages, allowing operators to maintain stable positioning of the workpiece during angled cuts, which increases precision and safety. In fabrication, prototyping, or custom component production, the tilting table allows operators to perform a wide range of angled cuts efficiently, making the machine a versatile tool for both one-off projects and batch production.

-

Miter Cutting Capabilities: Miter cutting is a critical requirement for applications that demand precise corner joints, frames, or angled components. The Vertical Band Sawing Machine often incorporates miter gauges, adjustable fences, or guide systems that facilitate accurate angled cuts at repeatable intervals. Most machines allow for miter angles ranging from 0° up to 60° or higher, depending on the model and table configuration. This functionality ensures that operators can produce consistent, high-quality cuts for both single items and batch operations. When combined with adjustable angles and tilting tables, miter cutting capabilities greatly expand the machine’s versatility, enabling complex cut patterns without sacrificing accuracy, even for high-volume production environments.

-

Enhanced Productivity and Versatility: The combination of adjustable cutting angles, tilting tables, and miter cutting capabilities makes the Vertical Band Sawing Machine exceptionally versatile for a wide array of applications. Operators can switch seamlessly between straight cuts, bevel cuts, and compound cuts without extensive reconfiguration or additional equipment. This flexibility not only streamlines workflow but also reduces downtime between operations. Industrial workshops, prototyping labs, and custom fabrication facilities benefit from the ability to process diverse materials—including metals, aluminum, plastics, and composites—on a single machine. The result is increased productivity, cost efficiency, and the capability to handle complex projects that would otherwise require multiple specialized cutting tools.

-

Precision and Stability: Despite its high degree of flexibility, the Vertical Band Sawing Machine maintains exceptional cutting precision through robust construction, accurate blade guides, and secure clamping mechanisms. Adjustable features such as tilting tables and miter guides are equipped with locking systems that prevent unintended movement during cutting, ensuring that both simple and complex angled cuts remain precise. This combination of flexibility and stability allows operators to achieve tight tolerances consistently, which is essential for industrial applications where precision is critical, such as metal fabrication, woodworking, aerospace components, or composite material cutting. The machine’s rigid frame, vibration-damping design, and precise mechanical adjustments guarantee reliable performance even under demanding, heavy-duty operations.

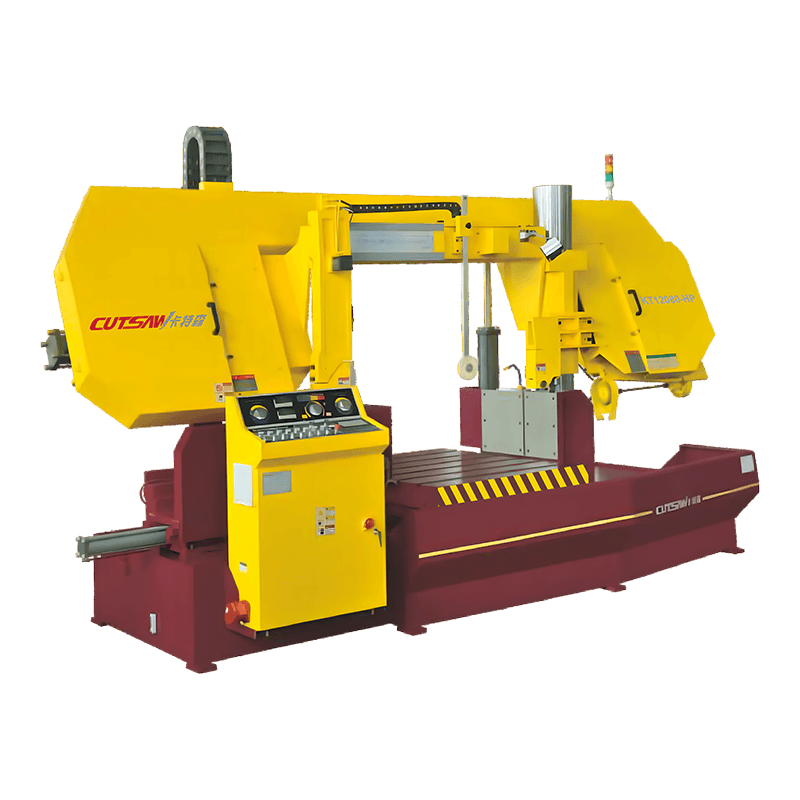

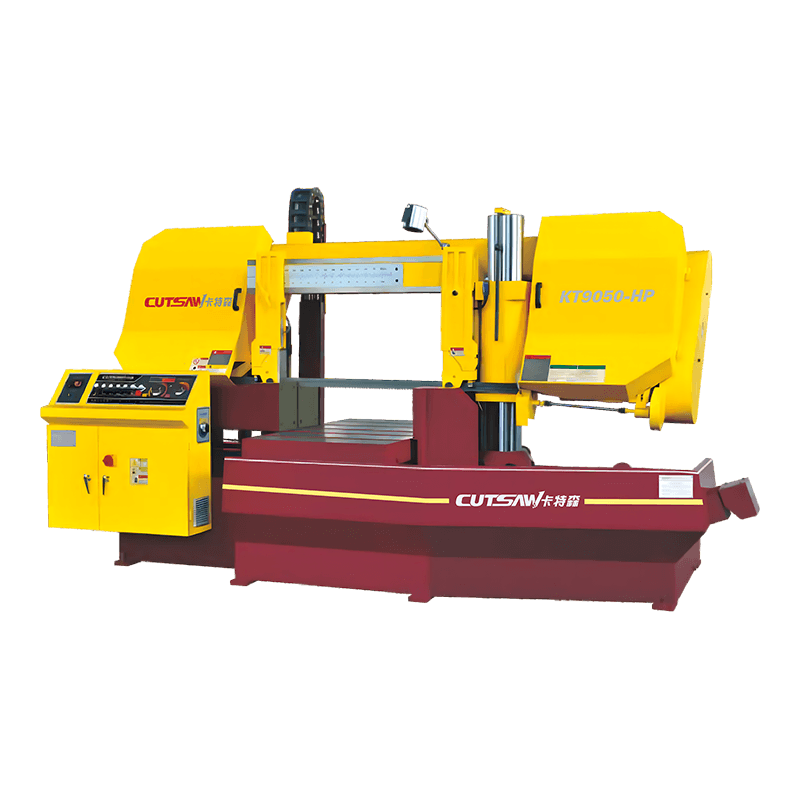

High performance, Good precision and Consumptive material saving CUTSAW design and manufacture high-performance KT series bandsaw in compliance with "high performance", "good precision"and "consumptiv...

See Details