Understanding the Scissors Sawing Machine

Defining the Machine

The Scissors Sawing Machine, often categorized as an advanced industrial cutting system, represents a significant evolution in material processing technology. Unlike conventional rotary saws or guillotine shears, this machine operates on a distinct kinematic principle that maximizes precision while minimizing material deformation and waste.

At its core, a scissors sawing machine is a specialized piece of equipment designed to cut various workpieces—ranging from large metal billets and profiles to delicate textile rolls and engineered plastics—using a mechanism that physically mimics the smooth, progressive action of a pair of scissors. This unique cutting motion involves two moving blades or a combination of a stationary base blade and a moving upper blade that converge to slice the material, rather than simply ripping or punching through it.

This method delivers a clean, controlled separation, making the scissors sawing machine indispensable across sectors where cut quality and material integrity are paramount. It serves as a cornerstone piece of equipment in high-volume production facilities, ensuring that initial material preparation meets the stringent standards required for subsequent manufacturing stages.

Core Functionality and Mechanism

The fundamental functionality of the scissors sawing machine is the controlled, angled convergence of its cutting edges. This mechanism is key to its performance and distinguishes it from other industrial cutters.

The Scissor-Like Cutting Action

The machine's namesake derives from this defining motion. Instead of the straight-down vertical force used in standard shearing or the abrasive action of a traditional saw, the scissors sawing machine utilizes a progressive angular cut:

- Angled Blades: The cutting blades are typically mounted at a slight, pre-determined angle relative to the material being cut and to each other.

- Point of Contact: The cutting process begins at one point along the blade's edge, creating a localized, highly concentrated force.

- Progressive Slice: As the powered drive system (motor and hydraulics/pneumatics) engages, the blades move past each other, extending the cutting action progressively across the entire width of the material. This acts like a continuous slicing motion rather than a simultaneous crush.

- Reduced Load: This progressive action significantly reduces the total instantaneous force required compared to a straight shear. By cutting a small cross-section at a time, the machine demands less power for the same volume of material, leading to reduced wear on the motor and drive system and quieter operation.

Primary Uses and Benefits

The design and mechanics of the scissors sawing machine translate directly into several key operational advantages:

| Feature | Primary Use | Direct Benefit |

| Progressive Shear Action | Processing high-strength materials (e.g., thick steel, composite bars). | Reduced Distortion: Minimized stress on the material, resulting in less bowing or warping of the finished piece. |

| Controlled Blade Speed | Cutting delicate or thin materials (e.g., films, textiles, thin gauge metal). | High Cut Quality: Provides burr-free, clean edges that often require little to no secondary finishing (deburring or sanding). |

| Robust Drive System | Continuous, high-volume production runs. | Efficiency and Longevity: Higher throughput rates and lower long-term maintenance costs due to reduced peak load on components. |

| Precision Clamping Mechanism | Ensuring dimensional accuracy in every cut. | Consistency: Highly accurate, repeatable cuts, crucial for automated downstream processing. |

Materials Effectively Cut

The versatility of the scissors sawing machine is one of its most compelling attributes, allowing it to handle a surprising spectrum of material types and profiles. The key to this adaptability lies in the ability to easily change the cutting blades and adjust the machine's parameters (like blade gap and speed) to suit the material's physical properties.

The scissors sawing machine can effectively cut:

- Ferrous Metals: Mild steel, stainless steel, tool steel in the form of sheets, plates, bars (round, square, hexagonal), and various structural profiles (angles, channels).

- Non-Ferrous Metals: Aluminum, brass, copper, and their alloys. The clean cutting action is particularly beneficial for soft metals to prevent smearing or excessive heat build-up.

- Plastics and Composites: Acrylic sheets, PVC pipes, fiberglass, carbon fiber sheets, and other engineered plastics where a clean edge is required to maintain structural integrity.

- Textiles and Leather: Large rolls of technical textiles, industrial fabrics, leather hides, and specific composite materials used in automotive or furniture manufacturing.

- Elastomers and Rubber: Various forms of industrial rubber products and thick elastomer sheets.

This wide operational range solidifies the scissors sawing machine as a multi-purpose workhorse, capable of transitioning between different manufacturing needs with minimal setup time.

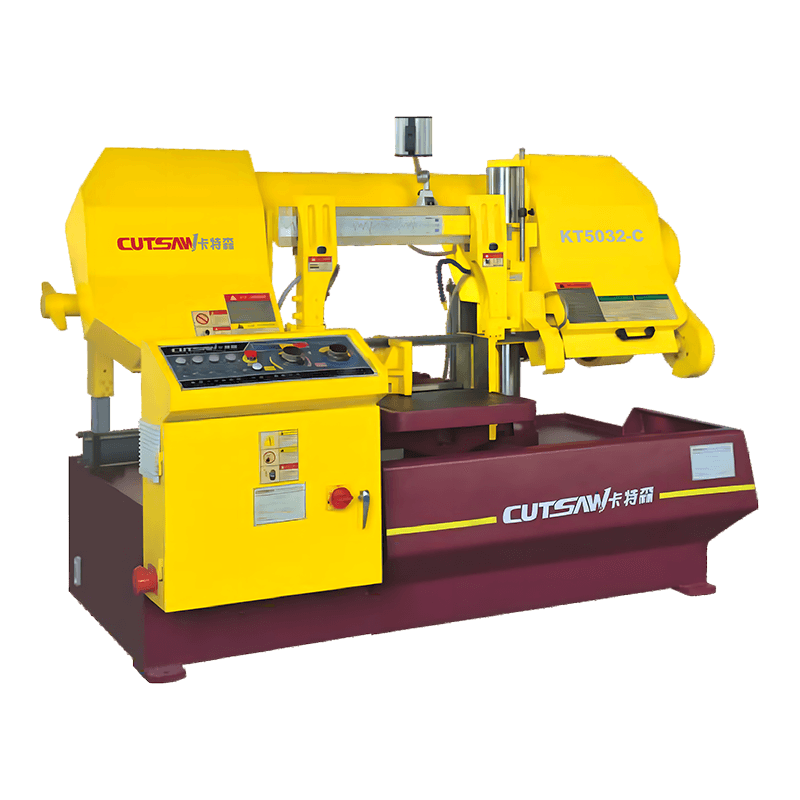

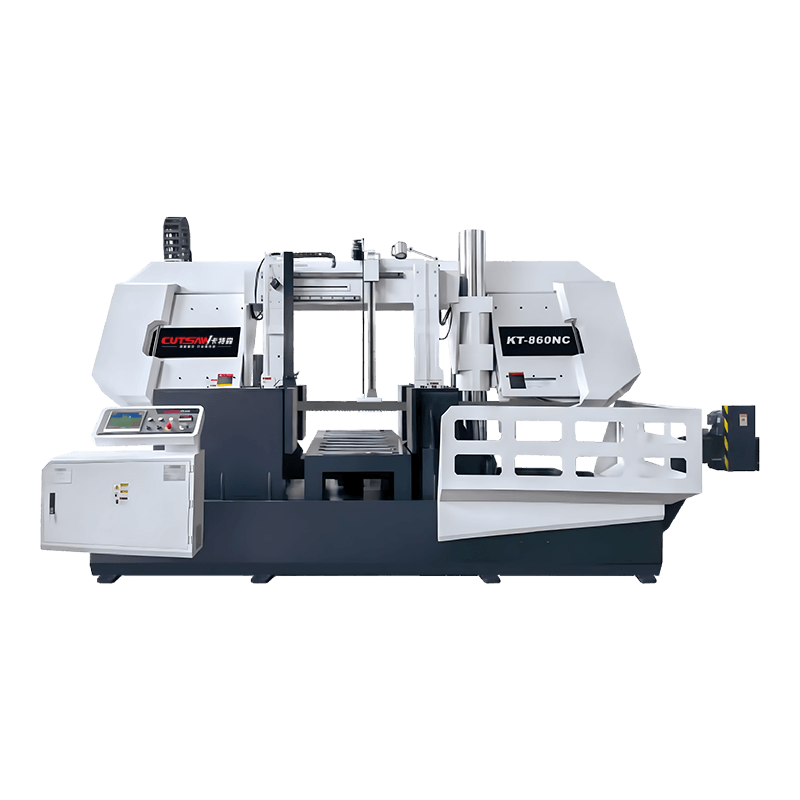

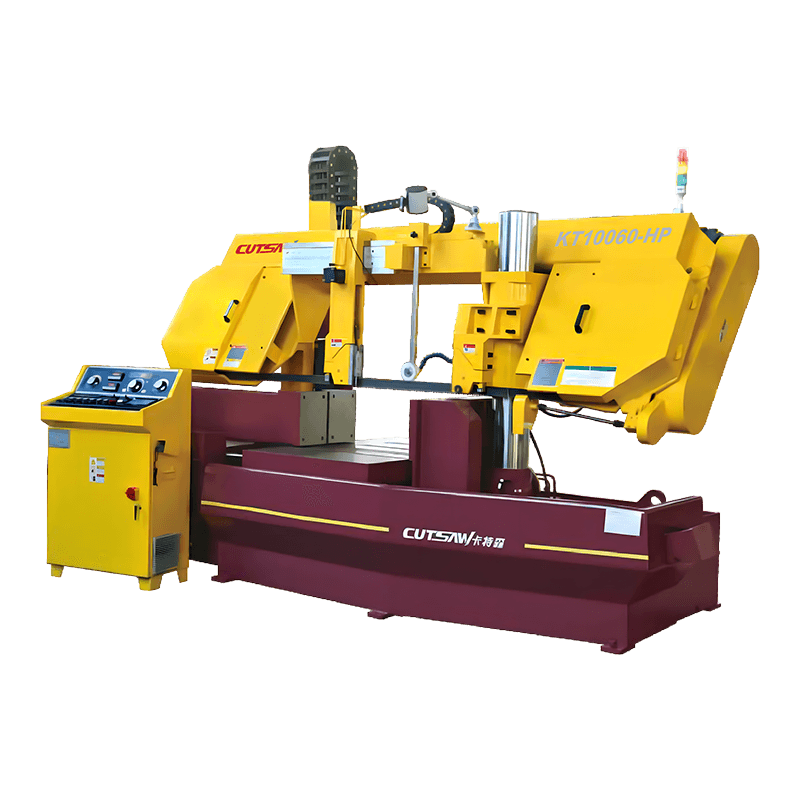

Exploring Types of Scissors Sawing Machines

The industrial landscape necessitates cutting tools with varying degrees of power, speed, and precision. Consequently, the scissors sawing machine has evolved into several distinct types, primarily classified by their power source and method of operation. Understanding these differences is crucial for selecting the equipment that aligns perfectly with specific production demands.

The primary types available in the market are the Hydraulic, Pneumatic, and Manual Scissors Sawing Machines.

Hydraulic Scissors Sawing Machines

Hydraulic Scissors Sawing Machines represent the pinnacle of power and control in this cutting technology. They utilize a hydraulic system—involving a motor, pump, fluid reservoir, and cylinders—to generate massive forces for actuating the cutting blades.

Features and Applications

- Features:

- High Force Output: Hydraulic fluid is non-compressible, allowing the system to transmit immense and stable force. This makes them ideal for cutting materials with high tensile strength or substantial thickness.

- Precise Speed Control: The flow rate of the hydraulic fluid can be finely modulated via valves, giving the operator exceptional control over the cutting speed. This variable speed is critical for preventing heat buildup in certain alloys or composites.

- Smooth Operation: Despite their power, hydraulic systems are known for a very smooth and deliberate cutting stroke, minimizing mechanical shock and vibration, which contributes to machine longevity.

- Heavy-Duty Construction: These machines are built with robust, heavy frames to withstand the reaction forces generated by the hydraulic system, ensuring stability during the cutting of demanding materials.

- Applications:

- Heavy-Duty Metal Cutting: Primary use includes cutting thick steel plates, large metal billets, and high-strength structural profiles (I-beams, H-beams).

- Automotive and Aerospace: Processing specialized alloys and composite materials used in these high-precision industries.

- Construction Fabrication: High-volume cutting of reinforcing bar (rebar) and various steel components for infrastructure projects.

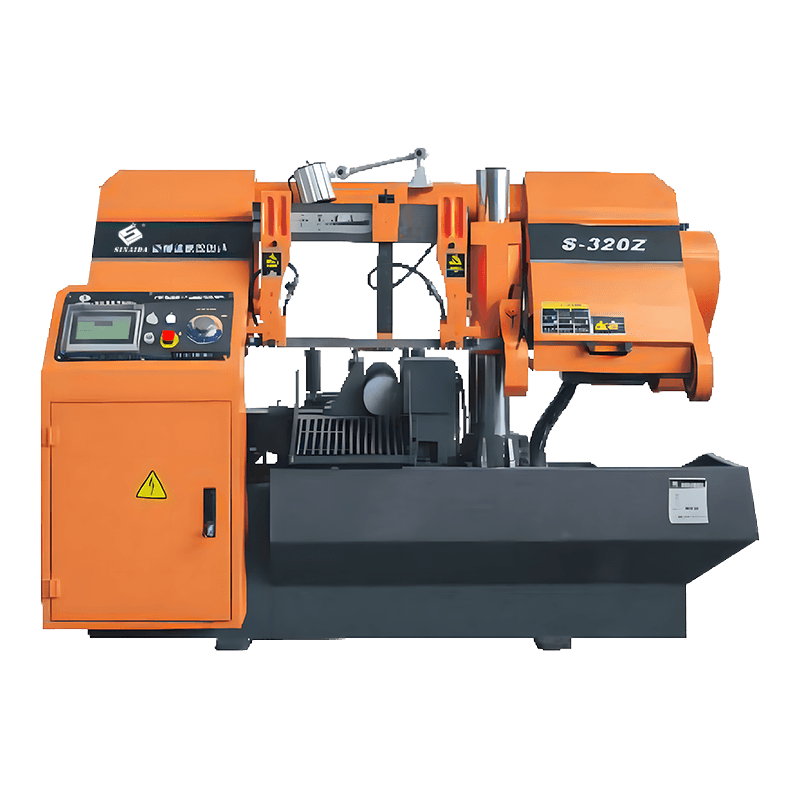

Pneumatic Scissors Sawing Machines

Pneumatic Scissors Sawing Machines are powered by compressed air, which drives cylinders to move the cutting blades. While they typically offer less peak cutting force than hydraulic models, they excel in speed, cleanliness, and rapid cycling.

Features and Applications

- Features:

- High-Speed Operation: Compressed air can actuate cylinders much faster than hydraulic fluid, resulting in rapid cycle times and high operational speed.

- Clean Environment: Pneumatic systems do not involve oil, making them inherently cleaner than hydraulic systems. This is a significant advantage in environments where contamination must be avoided.

- Ease of Maintenance: Pneumatic components are often simpler and easier to maintain, requiring less specialized knowledge compared to complex hydraulic circuits.

- Lower Initial Cost: The machinery and supporting infrastructure (air compressors) often have a lower initial capital outlay than heavy-duty hydraulic setups.

- Applications:

- Textile Manufacturing: High-speed, precise cutting of large rolls of fabric, technical textiles, and non-woven materials.

- Plastics and Films: Rapid trimming and sizing of thin gauge plastics, packaging films, and delicate polymer sheets.

- Light Metal Fabrication: Cutting thin sheets, wires, and small-diameter non-ferrous bars (e.g., aluminum or copper).

- Clean Room Environments: Their oil-free operation makes them suitable for use in facilities with strict cleanliness requirements.

Manual Scissors Sawing Machines

Manual Scissors Sawing Machines are generally smaller, portable units where the cutting force is applied directly by the operator, often through a lever mechanism or geared hand wheel to multiply the human input force.

Features and Applications

- Features:

- Portability and Compactness: These machines are highly mobile and require no external power source (besides the operator), making them ideal for field work or small workshops.

- Cost-Effectiveness: They represent the most affordable entry point into scissors sawing machine technology due to the absence of complex power units.

- Pinpoint Control: The operator has direct tactile feedback and control over the cutting process, allowing for very fine adjustments, especially useful for one-off or specialized cuts.

- Energy Independence: Operable without electricity or compressed air, offering versatility in remote locations.

- Applications:

- Small Workshop Operations: Ideal for hobbyists, craftspeople, or workshops with low-volume cutting needs.

- Specific Material Cuts: Often used for cutting specific components like plastic tubing, small rubber profiles, or light gauge metal strips.

- On-Site Installation Work: Perfect for cutting materials to size at an installation site where large industrial equipment is impractical.

Comparative Analysis: Power Source Comparison

To facilitate the decision-making process, the table below compares the key operational parameters of the three main types of Scissors Sawing Machines.

| Parameter | Hydraulic Scissors Sawing Machine | Pneumatic Scissors Sawing Machine | Manual Scissors Sawing Machine |

| Power Source | Electric Motor & Hydraulic Fluid | Compressed Air | Operator Force (Lever/Geared System) |

| Peak Force Output | Highest (Excellent for thick materials) | Medium (Suitable for thin to medium materials) | Lowest (Limited to light/small materials) |

| Cutting Speed/Cycle Time | Low to Medium (Slower, deliberate stroke) | High (Fast, rapid cycling) | Low (Dependent on operator speed) |

| Precision & Repeatability | Very High (Consistent hydraulic pressure) | High (Consistent air pressure) | Moderate (Dependent on operator skill) |

| Installation Complexity | High (Requires dedicated power unit, plumbing) | Medium (Requires dedicated air compressor/line) | Low (Requires only mounting) |

| Maintenance Profile | Complex (Fluid checks, seal replacement) | Simple (Air line checks, cylinder maintenance) | Very Simple (Blade and mechanical linkage) |

| Best Suited For | High-volume, heavy-duty metal fabrication. | High-speed, clean cutting of plastics and textiles. | Low-volume, portable, small-scale operations. |

Advantages and Disadvantages of Each Type

- Hydraulic Advantages: Unmatched power, exceptional control over the cut, superior edge quality on thick materials.

- Hydraulic Disadvantages: Higher initial cost, requires specialized maintenance, potential for fluid leaks, generally slower cycle speed than pneumatic.

- Pneumatic Advantages: Fast operation, clean (oil-free), quick setup, lower capital investment than hydraulic models.

- Pneumatic Disadvantages: Limited maximum cutting force, requires a constant, stable compressed air supply, potential for moisture in the air lines.

- Manual Advantages: Maximum portability, zero running costs (power), simplicity of use, very low initial cost.

- Manual Disadvantages: Minimal cutting capacity, operator fatigue is a factor, lower repeatability than powered machines.

Essential Components of a Scissors Sawing Machine

A Scissors Sawing Machine is a sophisticated system where the precision of the cut is derived from the coordinated function of several key, interrelated components. Understanding these parts is essential for both selecting the right machine and executing effective maintenance.

1. Cutting Blades: Material, Design, and Sharpening Techniques

The cutting blades are the contact point between the machine and the workpiece, and their characteristics are paramount to the quality and efficiency of the cut.

Material Selection

The material of the cutting blades must be significantly harder and more resilient than the material being cut. Common materials include:

| Blade Material | Key Characteristics | Typical Application |

| High-Speed Steel (HSS) | Good wear resistance; cost-effective; suitable for moderate speed cutting. | Mild steel, aluminum, thicker plastics. |

| High Carbon/High Chrome Steel (D2) | High resistance to abrasion and hardening capability; excellent for longevity. | Stainless steel, medium-gauge structural metals, heavy composites. |

| Tungsten Carbide-Tipped (TCT) | Extremely high hardness; exceptional heat resistance; the highest cost option. | Specialized alloys, highly abrasive materials, continuous high-volume cutting. |

| Tool Steel (Various Grades) | Balanced toughness and hardness; often used as a base material. | General-purpose metal and non-metal cutting. |

Design and Edge Geometry

Blade design is specific to the machine's model and the material's geometry (e.g., flat sheets versus angular profiles). Key design considerations include:

- Rake Angle: The angle of the blade face relative to the material flow. A positive rake is generally used for softer, less resistant materials (like aluminum or textiles) to facilitate easier slicing, while a more neutral or slightly negative angle is preferred for hard materials like steel to maximize edge strength.

- Clearance Angle (Relief): This angle ensures only the cutting edge, and not the entire blade flank, contacts the material, reducing friction and heat.

- Blade Gap (Clearance): This critical parameter is the space between the two cutting blades at the point of shear. It must be precisely set (often adjustable via shims or machine controls) based on the material thickness.

- *Too large a gap:* Causes poor cut quality, resulting in rolled edges, burrs, and potential material tearing.

- *Too small a gap:* Creates excessive friction and heat, leading to premature blade wear and potentially jamming.

Sharpening Techniques

Maintaining blade sharpness is vital for preserving the machine's precision cutting capability and reducing load on the motor and drive system. Sharpening typically involves:

- Grinding: Using precision grinding equipment to remove a minimal amount of material and restore the original edge geometry (rake and clearance angles).

- Honing/Lapping: A final finishing step, especially for blades used on delicate materials, to ensure a microscopically smooth and burr-free cutting edge.

- Frequency: Sharpening frequency is dependent on the type of material cut (abrasive materials require more frequent sharpening) and the volume of throughput. Regular monitoring of cut quality dictates the schedule.

2. Motor and Drive System: Power Transmission

The motor and drive system is the powerhouse that supplies the necessary kinetic energy for the cutting action. It determines the cutting speed, consistency, and the machine's overall capacity.

The Motor

Industrial scissors sawing machines typically utilize powerful, three-phase electric induction motors. The motor’s role is to convert electrical energy into mechanical energy.

- Key Parameters: Horsepower (HP) or Kilowatts (kW), rotational speed (RPM), and thermal rating (duty cycle). Larger hydraulic machines require more powerful motors to drive the hydraulic pump effectively.

The Drive System

The drive system is responsible for how power is transmitted to the blades and controlling the movement profile.

- Hydraulic Drive (in Hydraulic Machines): The motor drives a high-pressure hydraulic pump. This pump pressurizes the hydraulic fluid, which is then directed by control valves to the cylinders. The cylinder’s linear motion, amplified by mechanical linkages, creates the scissors-like cutting action. This system provides constant, high torque at low speeds.

- Pneumatic Drive (in Pneumatic Machines): The motor powers an air compressor (often external), and compressed air is routed to pneumatic cylinders. This system is faster for lighter loads but provides less sustained force than hydraulics.

- Mechanical Drive (for smaller/older models): Involves gears, flywheels, and clutches to translate the motor's rotational energy into the linear or oscillating motion of the blades.

3. Clamping Mechanism: Ensuring Material Stability

The integrity of the cut is highly dependent on the stability of the workpiece. The clamping mechanism is critical for ensuring material stability during the cutting process.

- Function: It holds the material rigidly against the machine's table or back gauge, preventing lateral, vertical, or rotational movement during the high-force shearing process.

- Types:

- Hydraulic Hold-Downs: Most common in high-capacity machines. Multiple hydraulic cylinders apply immense, uniform pressure across the material's surface just ahead of the cutting line.

- Pneumatic Hold-Downs: Used in lighter machines, offering faster actuation for materials like textiles or thin sheets.

- Mechanical Clamps: Used in manual or very simple machines, employing screws or levers.

- Key Requirement: The clamping force must be sufficient to counteract the lifting and twisting forces exerted by the cutting blades as they shear the material. If the clamping is inadequate, the material can slip, leading to inaccurate cuts, edge deformation, and potential damage to the blades.

4. Control Panel: Operation and Settings

The control panel is the interface through which the operator manages the operation and settings of the machine, ensuring safety, accuracy, and efficiency.

- Modern Control Panels (CNC/PLC): Advanced scissors sawing machines use Computer Numerical Control (CNC) or Programmable Logic Controllers (PLC) to manage complex operations.

- Digital Readouts (DROs): Provide real-time data on parameters like blade position, back gauge distance, and stroke speed.

- Batch Programming: Allows operators to input a sequence of cuts (e.g., cutting different lengths from a single bar) for automated processing, maximizing efficiency.

- Parameter Adjustment: Enables precise digital setting of critical parameters like blade gap, cutting pressure (in hydraulic models), and speed profile.

- Safety Interlocks: The panel integrates crucial safety functions, ensuring the machine cannot operate if protective guards are open or if the operator’s hands are near the cutting zone.

- Diagnostics: Modern panels often provide self-diagnostic feedback, alerting the operator to issues like low hydraulic fluid levels, motor overheating, or drive system errors, facilitating timely troubleshooting.

Maximizing Results: Benefits and Applications

The adoption of the Scissors Sawing Machine across various industries is driven by its exceptional ability to deliver high-quality, high-volume production. This section details the specific benefits that translate into operational improvements and explores its widespread application in modern manufacturing.

Key Benefits of Using a Scissors Sawing Machine

The unique mechanical action of the scissors sawing machine provides several distinct advantages over traditional cutting methods like abrasive sawing, plasma cutting, or non-powered shearing.

Precision Cutting

Precision Cutting is perhaps the most significant benefit, directly impacting material utilization and downstream processing costs.

- Accuracy and Clean Cuts Achieved: The progressive, low-impact slicing motion, coupled with the rigid clamping mechanism, minimizes vibration and material movement. This results in cut pieces with highly accurate dimensions and squareness.

- Reduced Burr Formation: Unlike abrasive saws, which generate thick, fused burrs, the clean shear action often results in a nearly burr-free edge. This drastically reduces the need for secondary finishing operations (deburring, grinding), saving both time and labor.

- Minimal Material Distortion: Because the cutting force is localized and spread progressively along the blade, the material experiences less stress and heat-affected zone (HAZ) damage compared to high-heat or high-impact cutting methods. This is crucial for maintaining the structural integrity of specialized metals and composites.

Efficiency

The speed and operational reliability of the machine lead to significant Efficiency and productivity gains.

- Speed and Productivity Gains:

- Rapid Cycle Time: Particularly in Pneumatic Scissors Sawing Machines, the speed of the blade actuation translates into higher pieces per minute (PPM) rates for continuous operations.

- Automation Integration: Modern machines integrate seamlessly with material handling systems (conveyors, feeders, automated back gauges), allowing for lights-out or minimal-operator production runs.

- Reduced Waste: Precise cuts and minimal HAZ mean less material is scrapped or wasted due to faulty cuts or thermal damage.

- Energy Consumption: Compared to some high-power cutting technologies (like lasers or heavy-duty presses), the hydraulic or pneumatic power unit often provides a favorable balance of force vs. energy draw for a given material thickness.

Safety

The design inherently integrates advanced Safety features compared to open blade systems.

- Safety Features and Precautions:

- Enclosed Cutting Zone: The cutting mechanism is usually fully enclosed, protecting operators from moving cutting blades and flying debris.

- Two-Hand Operation: Many machines require the operator to engage two simultaneous controls to initiate the cut, ensuring hands are clear of the dangerous zone.

- Overload Protection: Integrated into the Control Panel, electronic or hydraulic overload protection prevents the machine from operating outside safe parameters, protecting both the equipment and the operator.

Versatility

The adaptability of the machine allows it to handle a wide Range of materials and applications.

- Adaptable Blade Settings: By simply adjusting the blade material and the critical blade gap, the same basic machine frame can be optimized to cut materials ranging from soft textiles to hardened steel, providing excellent return on investment (ROI).

- Profile Handling: The machine is proficient not just with flat stock (sheets/plates) but also with complex profiles (angles, channels, tubes), provided the correct tooling or dies are employed.

Applications of Scissors Sawing Machines Across Industries

The benefits translate directly into critical roles within several major manufacturing sectors.

Metalworking

The scissors sawing machine is a foundational tool in metal fabrication and processing.

- Cutting Metal Sheets, Bars, and Profiles: Used for dimensionally accurate preparation of feedstock. This includes slicing large metal plates into smaller blanks (often replacing less precise shearing methods) and cutting long metal bars or tubing to specific component lengths.

- Structural Components: Essential for cutting angle iron, channels, and beams used in construction and heavy equipment manufacturing, where accuracy is necessary for proper welding and assembly.

Plastics Industry

In the plastics sector, the clean, low-heat cut is a non-negotiable requirement.

- Trimming and Cutting Plastic Components: Ideal for sizing thick acrylic or polycarbonate sheets without causing the heat buildup that leads to melting, gumming, or stress cracking along the cut edge.

- Pipe and Extrusion Cutting: Used for achieving smooth, square ends on PVC, polyethylene, and complex plastic profiles, eliminating rough edges that could compromise downstream assembly.

Textile Manufacturing

Pneumatic Scissors Sawing Machines are particularly valuable here due to their speed and cleanliness.

- Cutting Fabrics and Textiles Accurately: Employed for high-speed, continuous cutting of industrial fabrics (e.g., carbon fiber prepregs, Kevlar) or large garment pattern pieces, ensuring stacked layers are cut identically without shifting.

- Minimizing Fraying: The sharp, progressive shear action minimizes fraying on woven materials, a common problem with rotary cutters.

Woodworking

While traditional saws dominate this sector, specialized scissors sawing machines offer a clean, non-chipping cut for specific wood-based materials.

- Precision Cuts in Wood Materials: Used primarily for cutting high-density fiberboard (HDF), particleboard, and wood-plastic composites (WPC) where a smooth, splinter-free edge is required for immediate lamination or finishing without sanding.

Comparative Summary of Cutting Methods

To underscore the role of the Scissors Sawing Machine, a comparison with common industrial cutting methods highlights its niche.

| Cutting Method | Principle of Operation | Key Advantages | Primary Disadvantage |

| Scissors Sawing | Progressive, low-impact shear | High precision, low material distortion, minimal burr. | Limited to straight cuts; material thickness capacity is capped. |

| Abrasive Sawing | High-speed friction and heat | Can cut very hard metals; simple setup. | High heat generation (HAZ), significant burr, high material loss (kerf). |

| Guillotine Shearing | Single-stroke vertical impact | Extremely fast for thin sheets. | High impact stress, significant material deformation (bowing) on thick pieces. |

| Plasma/Laser Cutting | High-heat thermal erosion | Complex shapes/profiles possible; no mechanical contact. | High energy cost, wide HAZ, material discoloration, high fume extraction requirements. |

The Scissors Sawing Machine thus fills a vital role, providing a mechanical cutting solution that balances the speed of shearing with the precision and low deformation associated with specialized cutting.

How to Choose the Right Scissors Sawing Machine

Selecting the appropriate Scissors Sawing Machine is a critical investment decision that directly impacts operational efficiency, cut quality, and long-term operating costs. A thorough evaluation requires matching the machine’s technical specifications with the specific demands of the intended application.

Consider the Materials You Will Be Cutting

The composition and physical properties of the materials being processed are the primary determinants for machine selection.

- Material Hardness and Tensile Strength:

- Hard Metals (e.g., Tool Steel, High-Tensile Alloys): Requires a machine with maximum force output and rigidity, typically a high-capacity Hydraulic Scissors Sawing Machine. The cutting blades must be made of highly durable materials like Tungsten Carbide-Tipped (TCT).

- Soft Metals (e.g., Aluminum, Copper): Requires a machine with precise speed control to avoid smearing and excessive heat, which hydraulic or high-end pneumatic models can provide.

- Non-Metal Composites (e.g., Carbon Fiber, Thick Plastics): Focus should be on achieving a clean, low-impact cut to prevent material delamination or cracking. A smooth-stroke hydraulic or fast, controlled pneumatic system is preferred.

- Material Form and Profile: Will you be cutting flat sheets, round bars, or complex structural profiles? Ensure the machine's table and clamping mechanism can securely accommodate the largest dimensions and most complex shapes you intend to cut.

Evaluate the Required Cutting Capacity and Speed

Matching the machine's performance specifications to your production volume is crucial for maximizing efficiency and minimizing bottlenecks.

- Cutting Capacity (Thickness and Width):

- Thickness: This is the most important parameter. If you primarily cut 10 mm steel, ensure the machine’s rated capacity is at least 12 mm to allow a safety margin and maintain cut quality throughout the blade lifecycle.

- Width/Length: The machine's throat depth and bed length must accommodate the full width of the material you process.

- Production Speed (Cycle Rate):

- High-Volume Production: If you require hundreds or thousands of cuts per shift, a high-cycle rate Pneumatic Scissors Sawing Machine or a fast-acting hydraulic model with automated feeding is necessary.

- Low-Volume/Heavy-Duty: If cuts are sporadic but involve very thick material, the focus shifts to force and quality (Hydraulic) rather than pure speed.

- Automation Level: Does your process require simple single cuts, or complex, programmed batch cutting? Machines with integrated CNC/PLC Control Panels and automated back gauges offer the highest degree of repeatable precision cutting and efficiency.

Assess the Space Available in Your Workshop or Factory

The physical footprint and infrastructural needs of the machine must be compatible with your operating environment.

- Physical Footprint: Hydraulic Scissors Sawing Machines are large and heavy due to the robust frame and integrated power unit. Pneumatic and Manual options are significantly more compact.

- Power and Utility Requirements:

- Hydraulic: Requires significant electrical input for the Motor and Drive System (pump) and sufficient floor stability to handle the immense weight and forces.

- Pneumatic: Requires a dedicated supply of clean, dry compressed air at the specified pressure and volume (CFM/LPS).

- Material Handling Space: Consider not just the machine itself, but the necessary space for safely loading the raw material and unloading the cut pieces (often requiring overhead cranes or forklifts for heavy pieces).

Determine Your Budget and Consider Long-Term Operating Costs

The total cost of ownership (TCO) extends far beyond the initial purchase price.

- Initial Capital Investment:

- Highest: New, high-capacity Hydraulic machines with advanced CNC controls.

- Medium: Mid-range Pneumatic models.

- Lowest: Manual or small-scale Pneumatic units.

- Running Costs:

- Energy Consumption: Hydraulic motors can have high power draws during operation, impacting electricity bills.

- Consumables: The cost and frequency of replacing or sharpening cutting blades must be factored in, particularly if cutting abrasive materials.

- Maintenance: Hydraulic machines have higher maintenance costs (fluid replacement, seal checks) than the simpler pneumatic or manual systems.

Selection Criteria Comparison Table

The following table summarizes the decision matrix for selecting the most appropriate Scissors Sawing Machine type.

| Criteria | High-Capacity Hydraulic | Mid-Range Pneumatic | Small-Scale Manual |

| Material Priority | Thick/Hard Metals, High-Strength Composites | Thin Metals, Plastics, Textiles, Foils | Very Thin/Soft Materials, Small Volumes |

| Cutting Capacity | ≥ 10 mm thickness; ≥ 3 m length | ≤ 6 mm thickness; ≤ 2 m length | ≤ 2 mm thickness; short lengths |

| Production Speed | Medium (Focus on Force/Quality) | High (Focus on Cycle Rate) | Low (Focus on Control/Portability) |

| Cut Quality | Excellent (Minimal HAZ, clean edge on heavy stock) | Very Good (Clean edge, rapid cycle) | Good (Dependent on operator skill) |

| Space Required | Large Footprint, High Ceiling | Moderate Footprint | Minimal, Tabletop or Portable |

| Infrastructure Need | Heavy Power (3-Phase), Stable Foundation | Compressed Air Supply | None (Self-Contained) |

| TCO | High (Initial cost + High maintenance) | Moderate (Lower initial cost, medium running cost) | Low (Minimal running cost) |

By meticulously reviewing these factors, a buyer can ensure the Scissors Sawing Machine purchased is optimally matched to their operational workflow, delivering the highest levels of precision cutting and production efficiency.

Maintenance and Safety Tips

The longevity, reliability, and sustained high performance of a Scissors Sawing Machine are heavily reliant on adherence to a rigorous schedule of maintenance and strict compliance with safety protocols. Proper upkeep ensures the machine maintains its capability for precision cutting and minimizes unexpected downtime, thereby maximizing production efficiency.

Regular Cleaning and Lubrication

Dirt, metal shavings, plastic dust, or textile fibers (depending on the application) are the enemies of precision machinery. Establishing a daily and weekly cleaning routine is essential.

- Daily Cleaning:

- Debris Removal: Utilize industrial vacuums and brushes to remove all material scraps and dust from the cutting table, the area around the cutting blades, and the clamping mechanism. Allowing debris to accumulate can interfere with blade movement and clamping pressure.

- Wipe-Down: Wipe down the machine frame and control surfaces to prevent dust from entering electrical components or hydraulic/pneumatic lines.

- Lubrication Schedule:

- Moving Parts: Regularly check and lubricate all articulated joints, pivots, and slides according to the manufacturer's specified lubricant type (e.g., specialized machine oil, grease). This minimizes friction and wear on the Motor and Drive System components.

- Hydraulic System Check (for Hydraulic Models): Check the hydraulic fluid level daily. Contaminated or low fluid is a common cause of pump failure and inconsistent cutting pressure. Fluid and filter replacement schedules must be strictly followed (typically every 2,000 to 4,000 operating hours).

- Pneumatic System Check (for Pneumatic Models): Drain moisture from the air receiver tank daily. Check in-line filters and lubricators to ensure the air supply is clean and appropriately lubricated (if the machine requires lubricated air).

Blade Maintenance and Sharpening

The performance of the cutting blades is the most critical factor influencing cut quality and machine load.

- Visual Inspection: Inspect the blades at the beginning of every shift for signs of chipping, cracking, or dulling. Even minor damage can cause material tearing, excessive burrs, and high strain on the Motor and Drive System.

- Blade Gap Adjustment: Regularly check and, if necessary, adjust the blade gap (clearance) using precision gauges, especially after changing material thickness or blade sets. Improper blade gap accelerates wear and compromises precision cutting.

- Sharpening Protocol:

- Timely Removal: Do not wait until the blade is severely dull. A slightly dull blade causes significantly more wear on the machine than a sharp one. Implement a system for tracking cuts or observing cut quality deterioration to determine sharpening frequency.

- Professional Sharpening: Cutting blades must be sharpened by specialized services using precision grinding equipment to maintain the correct original rake and clearance angles. Improper sharpening voids the blade's performance characteristics and can be dangerous.

- Blade Replacement: When the blade reaches its minimum usable width (after multiple sharpenings), it must be replaced to maintain structural integrity and correct geometry.

Safety Precautions and Guidelines

Safety must be the primary consideration during all phases of operation—from setup to cutting to maintenance.

- Personnel Safety:

- Personal Protective Equipment (PPE): Operators must wear appropriate PPE, which typically includes safety glasses (to guard against flying debris), steel-toed boots, and, depending on the noise level, hearing protection.

- Loose Clothing/Jewelry: Never operate the machine while wearing loose clothing, ties, or jewelry that could become snagged in the moving drive system or blades.

- Machine Operational Safety:

- Never Override Interlocks: The safety interlocks on access panels or guards are non-negotiable. Bypassing them exposes the operator to extreme danger and is strictly prohibited.

- Secure Clamping: Always ensure the clamping mechanism is fully engaged and the material is secured before initiating a cut.

- Authorized Use: Only trained and authorized personnel should operate the Scissors Sawing Machine. Training must cover all operational features, safety protocols, and emergency stop procedures (E-Stop).

- Lockout/Tagout (LOTO): Before performing any maintenance, adjustment, cleaning, or blade change, the machine's power source must be completely disconnected and locked out according to LOTO procedures to prevent accidental start-up.

Common Troubleshooting Tips

Addressing minor operational issues quickly can prevent them from escalating into major machine failures.

| Symptom | Probable Cause | Corrective Action |

| Material Tearing/Excessive Burr | Blade gap is too large or cutting blades are dull. | Adjust blade gap (reduce clearance) or replace/sharpen blades. |

| Machine Slows/Stalls During Cut | Low hydraulic pressure; Motor overload; Material hardness exceeds capacity. | Check hydraulic fluid level/filter; Consult capacity chart; Adjust blade speed (if variable). |

| Inaccurate Cut Length/Squareness | Material slippage; Clamping mechanism failure; Back gauge misalignment. | Increase clamping force; Inspect clamp pads; Verify back gauge reading via the Control Panel. |

| Loud, Abnormal Noises | Lack of lubrication in pivot points; Hydraulic pump cavitating; Loose components. | Check lubrication points; Check hydraulic fluid for air/low level; Tighten mounting bolts. |

By committing to proactive maintenance and strict adherence to safety guidelines, industrial operations can harness the full power and reliability of their Scissors Sawing Machine assets.

FAQs About the Scissors Sawing Machine

This section addresses common inquiries regarding the operation, longevity, capacity, and management of Scissors Sawing Machines, serving as a quick reference for operators and decision-makers.

Q1: What is the lifespan of a typical scissors sawing machine?

The lifespan of a high-quality Scissors Sawing Machine is substantial, typically ranging from 15 to 30 years in industrial environments, provided rigorous maintenance is performed.

- Hydraulic and Heavy-Duty Models: These generally have the longest lifespans (closer to 25–30 years). Their heavy, reinforced steel frames are built to withstand high forces, and major components like the hydraulic pump, motor, and cylinders are often designed for high-hour operation and are replaceable or rebuildable.

- Pneumatic Models: These often have slightly shorter structural lifespans (15–20 years) under continuous heavy use, primarily due to the simpler construction and faster cycling, which can induce more fatigue. However, their components are also readily maintained.

- Key Longevity Factors: The actual lifespan is most dependent on consistent regular cleaning and lubrication, adhering to material capacity limits, and timely replacement/maintenance of the cutting blades and seals.

Q2: How often should the cutting blades be replaced or sharpened?

The frequency for blade maintenance is not fixed; it is entirely dependent on the material being cut, its thickness, and the production volume.

| Factor | Effect on Blade Lifespan | Typical Sharpening Interval |

| Material Hardness | Cutting high-tensile steel wears blades much faster than soft aluminum. | Hard Steel: 5,000 to 10,000 cuts |

| Material Thickness | Cutting at maximum machine capacity induces the highest wear. | Mid-Range Materials: 10,000 to 20,000 cuts |

| Material Abrasiveness | Highly abrasive materials (e.g., ceramics, certain composites) dull the edge quickly. | Soft Materials (Plastics/Textiles): 20,000 to 50,000 cuts |

| Required Cut Quality | Processes requiring ultra-high precision cutting demand more frequent sharpening. | Ultra-Precision: Sharpening at the first sign of edge dullness. |

General Guideline: Blades should be sharpened immediately upon noticing a discernible drop in cut quality (increased burr, material pulling, or excessive machine noise/strain on the Motor and Drive System). Waiting too long can result in permanent damage to the blade geometry, making proper sharpening impossible.

Q3: Can a single machine handle a wide variety of materials effectively?

Yes, the Scissors Sawing Machine is highly versatile, but there are practical limits:

- Versatility in Form: A single machine can effectively cut sheets, bars, and certain profiles, provided the appropriate tooling and secure clamping mechanism are in place.

- Versatility in Material: A machine designed for heavy-duty metal fabrication (Hydraulic) can typically cut lighter materials like plastics or textiles, but it may be less efficient (slower cycle time) than a specialized Pneumatic machine.

- Critical Adjustments: To switch between materials, the operator must change the cutting blades (e.g., from TCT for steel to HSS for aluminum) and precisely adjust the blade gap. Failing to adjust the blade gap when switching from thick to thin material will result in poor quality cuts and premature wear.

- Conclusion: While versatile, optimal efficiency and cut quality are achieved when the machine type (Hydraulic vs. Pneumatic) is matched to the primary range of materials and production rate required.

Q4: What kind of training is required to operate this machine safely?

Comprehensive training is mandatory to ensure both operator safety and machine longevity, aligning with the principles outlined in the Safety Precautions and Guidelines.

- Operational Training: Must cover machine start-up, setting parameters via the Control Panel, initiating and stopping cuts, and managing the material flow.

- Safety Training: In-depth training on all safety features, including the proper use of clamping mechanism safeguards, safety interlocks, and the mandatory application of Lockout/Tagout (LOTO) procedures during maintenance or cleaning.

- Technical Training: This includes diagnosing common troubleshooting issues, performing regular cleaning and lubrication, and the correct procedure for blade removal and installation. Only specialized personnel should be trained in internal system maintenance (e.g., hydraulic pump adjustments).

Q5: Is the noise level significantly different between hydraulic and pneumatic models?

Yes, there is often a notable difference, which impacts the working environment:

- Hydraulic Scissors Sawing Machines: The primary noise source is the continuous running of the electric motor and the hydraulic pump when building or maintaining pressure. This noise is typically a low-frequency hum, which can be loud but steady. The actual cut is relatively quiet due to the smooth, low-speed slicing action.

- Pneumatic Scissors Sawing Machines: The primary noise sources are the constant running of the external air compressor and the sharp, high-decibel *hiss* of air exhaust as the pneumatic cylinders complete their stroke. The noise is often more frequent and potentially more disruptive than the steady hum of a hydraulic unit.

- Mitigation: For both types, adherence to Safety guidelines regarding hearing protection is often necessary, and noise reduction measures (e.g., sound-dampening enclosures or remote pump placement) may be implemented.