Introduction to Vertical Band Sawing Machines

Band sawing machines have become essential tools in various industries for cutting a wide range of materials, from metals to wood. These machines utilize a continuous band saw blade, making them efficient for precise, clean cuts. Among the different types of band sawing machines, the vertical band sawing machine stands out due to its unique design and functionality.

Overview of Band Sawing Machines

Band sawing machines are widely used in manufacturing and fabrication industries for their ability to make accurate, straight, and curved cuts on a variety of materials. These machines use a long, continuous saw blade that runs on two or more wheels. The band saw blade's flexibility allows it to cut through materials with great precision. The two main types of band saws are horizontal and vertical band saws, each offering different advantages depending on the application and material being cut.

In a typical band saw machine, the material is fed into the rotating blade, which is driven by an electric motor. The blade moves continuously around the wheels, maintaining consistent cutting performance. While horizontal band saws are more commonly used for cutting large, bulky materials like metal stock, vertical band saws are more versatile and are often used in applications requiring precise cuts in both metals and woods.

Vertical Band Sawing Machine: Features and Characteristics

The vertical band saw differs from its horizontal counterpart primarily in its orientation. The blade in a vertical band saw runs vertically, and the material is usually fed horizontally through the blade. This orientation allows for greater flexibility in cutting different shapes and sizes of materials, especially when precision and versatility are required. Vertical band saws are equipped with a stationary worktable, which can be adjusted for different angles, enabling the user to perform more intricate cuts with ease.

One of the key advantages of the vertical band saw is its ability to make cuts in irregularly shaped materials, such as curves or contours. The machine’s design allows for a clear view of the cutting area, improving accuracy and control. The blade’s tension can be adjusted, ensuring the saw blade remains firm and straight throughout the cutting process, reducing the risk of bending or warping during operation.

Another important feature of the vertical band saw is its use of specialized band saw blades, which come in various materials, thicknesses, and tooth configurations. Depending on the material being cut, different blade types can be chosen to optimize cutting efficiency. For example, metal cutting band saw blades are typically made from high-speed steel (HSS) or bi-metal for durability, while wood cutting band saw blades are generally made from carbon steel or stainless steel.

Applications of Vertical Band Saws

Vertical band sawing machines are widely used in different industries due to their versatility and ability to handle a wide range of materials. From metalworking to woodworking, these machines are essential for performing various cutting tasks that require precision and consistency. Below are some of the main applications of vertical band saws:

Metalworking

In metalworking, vertical band saws are commonly used for cutting sheet metal, pipes, rods, and other metal components. Metal cutting band saws are equipped with specialized blades designed to handle the hardness and density of metals, ensuring clean and accurate cuts. Vertical band saws are often preferred for smaller-scale, detailed work such as cutting intricate shapes and profiles in metal. They are also used for cutting thinner metal sheets or bars, where horizontal band saws might not be as efficient.

Woodworking

Wood cutting band saws are widely used in woodworking shops for tasks such as cutting logs, lumber, plywood, and making curved cuts in furniture components. Vertical band saws are particularly useful in cutting complex shapes and contours, such as those required for custom woodworking or cabinetry. The ability to adjust the height and angle of the worktable adds flexibility to the cutting process, allowing woodworkers to make precise bevels and angled cuts. The vertical orientation is ideal for cutting thin or irregularly shaped pieces of wood.

Other Industries

Beyond metalworking and woodworking, vertical band saws also find applications in other industries such as plastics fabrication, food processing, and even textile manufacturing. For example, in the food industry, vertical band saws are used to cut meat and other food products into precise portions. In plastics manufacturing, they are employed to cut plastic sheets and other materials used in packaging or product manufacturing.

Components and Technology in Vertical Band Saws

Modern vertical band saws are equipped with a variety of components and advanced technologies to enhance their performance and precision. These components include band saw guides, which help maintain the alignment of the blade during operation, ensuring straight cuts. The band saw guide system is crucial for reducing blade wear and ensuring consistent cutting quality.

In addition to traditional mechanical components, many vertical band saws are now available with CNC (Computer Numerical Control) capabilities. CNC band saws allow for automated control of the cutting process, making them ideal for high-volume production environments. These machines can be programmed to perform specific cuts with a high degree of accuracy, reducing the need for manual intervention and improving overall efficiency.

Choosing the Right Vertical Band Saw

When selecting a vertical band saw, it’s important to consider several factors to ensure that the machine meets the requirements of your specific application. The key factors include the type of material being cut, the desired cutting precision, and the volume of work. For instance, if you primarily work with metal, a metal cutting band saw with robust, high-performance blades and a powerful motor may be required. Similarly, for woodworking, a machine designed for precise, clean cuts in wood, with appropriate blade options, is essential.

Another important consideration is the size of the machine. Vertical band saws come in various sizes, from compact models suitable for small workshops to large, industrial machines capable of cutting through heavy-duty materials. It’s also important to check the machine’s maximum cutting capacity, including the height and width of the materials it can accommodate, as well as its cutting speed and blade tension adjustments.

Maintenance and Care

To keep a vertical band saw in optimal working condition, regular maintenance is necessary. This includes inspecting the band saw blades for wear and tear, as well as ensuring that the band saw guides are properly aligned and lubricated. Additionally, the machine’s motor and electrical components should be checked regularly to avoid overheating and ensure consistent performance. Blade tension must also be checked frequently to prevent unnecessary strain on the saw blade and to ensure precise cutting.

Vertical Band Saw vs Horizontal Band Saw

| Feature | Vertical Band Saw | Horizontal Band Saw |

|---|---|---|

| Orientation | Vertical blade orientation | Horizontal blade orientation |

| Cutting Range | Ideal for precise, intricate cuts | Better for cutting large, bulky materials |

| Material Types | Used for metal, wood, plastics, and more | Primarily used for cutting metal, pipes, and bars |

| Applications | Woodworking, metalworking, plastics, food processing | Heavy-duty metal cutting, large stock materials |

| Blade Types | Custom blades for wood and metal cutting | Heavy-duty blades designed for tougher materials |

Types of Vertical Band Sawing Machines

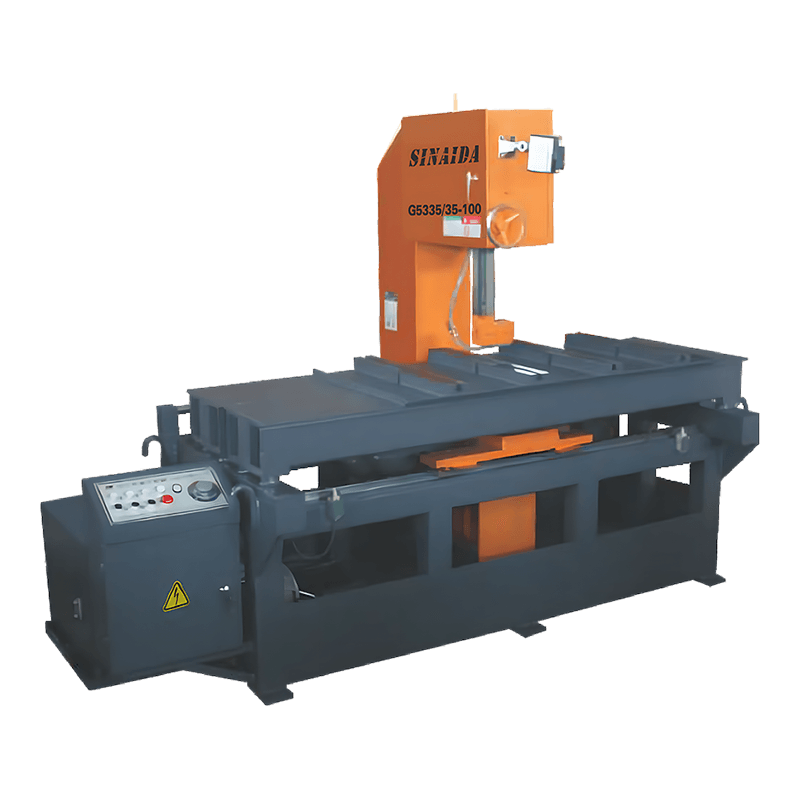

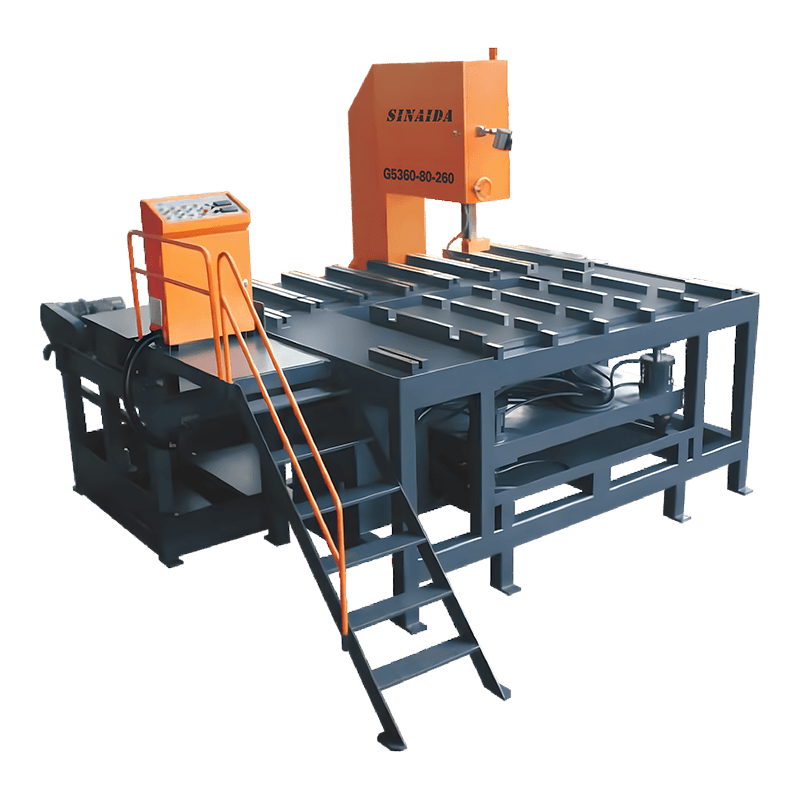

Standard Vertical Band Saws

Standard vertical band saws are the most commonly used machines in workshops, industries, and small-scale operations. These machines are designed for general-purpose cutting tasks, making them suitable for a wide variety of materials, including metal, wood, plastics, and more. The standard vertical band saw is ideal for users who need a reliable machine for everyday cutting tasks that do not require highly specialized features or automated processes.

One of the key features of standard vertical band saws is their ability to handle both straight and curved cuts, which makes them versatile for different types of work. These saws are equipped with adjustable worktables that allow operators to tilt the material and perform angled cuts. The band saw blades used in these machines can vary in material, thickness, and tooth configuration, depending on the material being cut. For instance, a wood cutting band saw typically uses a finer blade with teeth spaced for smoother cuts, while a metal cutting band saw may require a tougher blade made from high-speed steel (HSS) or bi-metal for durability.

Standard vertical band saws are commonly used in woodworking, metalworking, and small fabrication shops. They are suitable for cutting straight lines, circles, and even complex curves. The setup of these machines is relatively simple, making them accessible to users with varying levels of experience. While they are versatile, these saws may not be ideal for high-volume or highly complex cutting tasks, which require more automation or precision.

Contour Band Saws

Contour band saws, as the name suggests, are designed specifically for making intricate and detailed cuts. These machines are often used in industries where precise curves and shapes need to be cut into materials, particularly in woodworking and metalworking. Contour band saws feature a small, narrow blade that allows for greater maneuverability and flexibility, enabling operators to follow complex patterns and profiles with ease.

The key feature of a contour band saw is its ability to cut tight curves and detailed shapes. This is achieved by using a thinner band saw blade that is capable of bending around sharp curves without losing cutting efficiency. The vertical orientation of the blade allows for better control over the material and makes it easier to track complex shapes. Contour band saws are especially useful in tasks like cutting out detailed wooden parts for furniture or carving shapes in metal for artistic or functional purposes.

In addition to their precise cutting ability, contour band saws also offer the advantage of a larger cutting area and more clearance between the blade and the table, which allows for cutting larger and thicker materials. The band saw guides in these machines are often more refined to help maintain the blade's stability, ensuring consistent, clean cuts. Whether you are working with metal or wood, the contour band saw is a valuable tool for applications that require high precision in shape cutting.

Types of Vertical Band Sawing Machines

| Type of Vertical Band Saw | Key Features | Applications |

|---|---|---|

| Standard Vertical Band Saw | General-purpose saw for various materials, adjustable worktable, simple setup | Woodworking, metalworking, small-scale fabrication |

| Contour Band Saw | Thin, flexible blade for intricate cuts, ideal for tight curves and detailed shapes | Wood carving, metal shaping, custom furniture production |

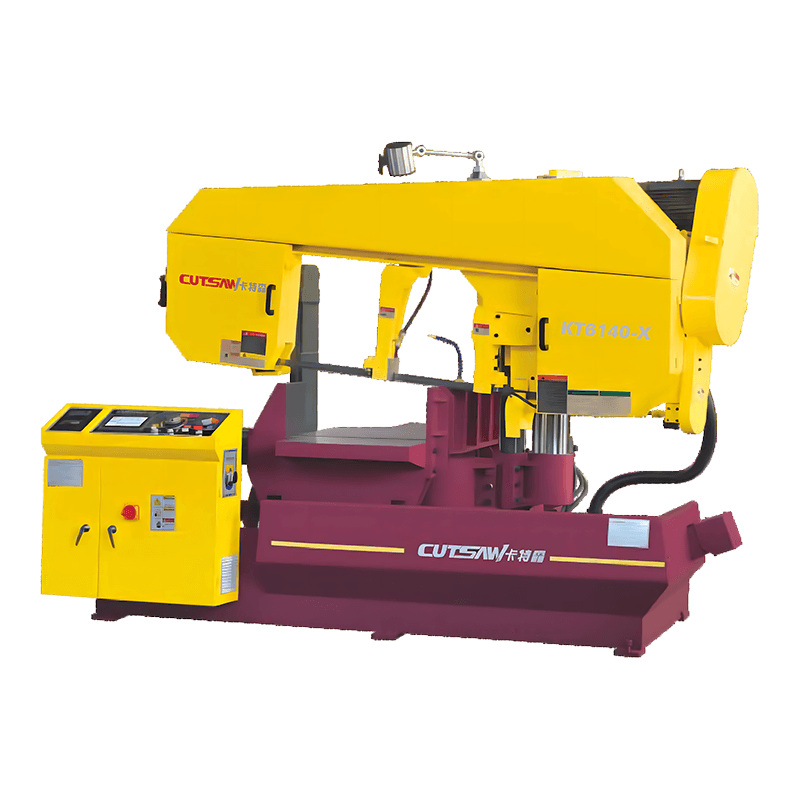

Automatic Vertical Band Saws

Automatic vertical band saws are designed to improve efficiency and precision in high-volume production settings. These machines integrate automated feeding and cutting processes, which significantly reduce the need for manual labor and increase throughput. Automatic band saws are commonly used in industries where large quantities of materials need to be processed quickly and accurately, such as in manufacturing, construction, and metal fabrication.

The main feature of automatic vertical band saws is the inclusion of an automated material feeding system. This system allows the material to be loaded into the machine and fed into the blade automatically, reducing the time and effort required to prepare and operate the saw. The saw blade is automatically adjusted and guided during the cutting process, ensuring consistent cuts without the need for manual adjustments. The result is faster production times, reduced human error, and more precise cuts, especially when working with metal cutting band saws or large pieces of wood.

In addition to automatic feeding, these band saws often include advanced cutting controls and monitoring systems. These systems can track the cutting progress, adjust the cutting speed, and even stop the machine if a problem is detected, ensuring safety and reducing the risk of accidents. Automatic vertical band saws are ideal for applications that require continuous operation, such as cutting large quantities of metal, plastic, or wood for construction projects or mass production lines.

CNC Vertical Band Saws

CNC (Computer Numerical Control) vertical band saws represent the most advanced type of vertical band saw, offering high precision and automation. These machines are equipped with a computer-controlled system that allows for intricate, automated cutting paths and precise adjustments throughout the cutting process. CNC band saws are commonly used in industries that require complex cuts and tight tolerances, such as aerospace, automotive, and high-end furniture manufacturing.

The primary advantage of CNC vertical band saws is their ability to provide highly precise, repeatable cuts with minimal operator intervention. Using computer programming, these machines can be set to follow complex cutting patterns and automatically adjust blade speed, tension, and cutting pressure to achieve optimal results. CNC band saws are particularly useful when cutting irregularly shaped materials, such as metal profiles or custom wood components, which require a high degree of accuracy.

Another benefit of CNC band saws is their ability to integrate with other automated systems in a production line. This can include linking the band saw to an inventory management system or a robotic arm that moves materials into position. CNC machines are equipped with advanced band saw guides that help maintain precise alignment of the saw blade, even during high-speed cutting. As a result, CNC band saws are capable of achieving complex cuts with remarkable consistency, making them ideal for industries where high-quality precision is essential.

Key Features and Components of Vertical Band Sawing Machine

Blade Guides

Blade guides are an integral part of a vertical band sawing machine, playing a significant role in ensuring the blade remains stable and tracks accurately throughout the cutting process. These guides are positioned at key points above and below the workpiece to provide support, preventing the blade from wandering off course. Inaccurate tracking can result in uneven cuts, blade damage, and excessive wear, which can be costly and time-consuming. Therefore, maintaining proper blade alignment is crucial, especially when dealing with more challenging materials such as metals, where precision is paramount.

Vertical band saws are equipped with different types of blade guides, including roller guides, ball-bearing guides, and carbide guides. Each type serves a specific purpose, with carbide guides being preferred for metal cutting band saws due to their higher durability and resistance to wear. The guides are adjustable, allowing operators to modify their positioning based on the material being cut and the thickness of the saw blade. This flexibility ensures that the saw is optimized for different cutting tasks, whether it's cutting wood or more abrasive materials like metal.

Blade Tensioning System

The blade tensioning system is crucial for maintaining optimal performance and precision during the cutting process. Proper blade tension ensures the saw blade remains taut and stable, preventing issues such as blade deflection or snapping. If the tension is too low, the blade may not cut effectively, resulting in poor quality cuts. On the other hand, if the tension is too high, it can lead to premature wear of both the blade and the saw's components. Maintaining the right blade tension is essential for achieving smooth, accurate cuts.

In most vertical band sawing machines, blade tension can be manually adjusted using a tensioning wheel or lever. This manual adjustment allows operators to set the appropriate tension based on the blade size and the material being cut. Advanced models, such as CNC band saws, often feature automatic blade tensioning systems that make real-time adjustments based on feedback from the saw's operation. These systems ensure that the blade maintains consistent tension throughout the cutting process, which is especially useful for high-volume production or more precise cutting tasks.

Work Table

The work table in a vertical band saw is designed to provide a stable surface to support materials during the cutting process. Made from durable materials like cast iron or steel, work tables are built to withstand the pressures of sawing while maintaining flatness and stability. Many work tables are adjustable, allowing the operator to modify the angle of the table for beveled or angled cuts. This feature is especially valuable when making cuts that require precision, such as those used in woodworking or metalworking applications.

To further enhance functionality, many band saws come with integrated clamping systems or hold-down devices on the work table. These features help secure the material in place, reducing the risk of movement during the cutting process and ensuring more accurate cuts. For wood cutting band saws, these features are especially important, as wood can shift or splinter during cutting. Some work tables also include measurement grids to assist operators in positioning materials accurately and performing repetitive cuts. Ensuring the work table is kept clean and free from debris is key to maintaining consistent cutting performance.

Key Features Comparison Table

| Component | Function | Importance |

|---|---|---|

| Blade Guides | Maintain blade alignment, reduce vibration | Ensure precise cuts, extend blade life |

| Blade Tensioning System | Maintains correct blade tension | Improves cutting accuracy, prolongs blade lifespan |

| Work Table | Provides stable support for material, adjustable for different angles | Enhances cutting precision and versatility |

| Coolant System | Cools the blade and reduces heat buildup | Prevents overheating, improves cutting performance |

| Motor and Drive System | Provides power and controls blade speed | Ensures smooth operation and cutting efficiency |

Coolant System

The coolant system is an essential component of vertical band sawing machines, especially when working with materials that generate high levels of heat during cutting, such as metal. Friction between the blade and the material can cause significant heat buildup, which can lead to blade warping, premature wear, and reduced cutting efficiency. The coolant system circulates a cooling fluid—typically a mixture of oil and water—over the blade and the workpiece to dissipate this heat and reduce friction. This results in smoother cuts and extends the lifespan of the blade.

For metal cutting band saws, oil-based coolants are often preferred due to their superior cooling and lubrication properties. These coolants help prevent metal chips from adhering to the blade, which can lead to wear or clogging. For wood cutting band saws, water-based coolants are typically used, as they are easier to clean and pose fewer environmental concerns. In addition to cooling the blade, the coolant system helps wash away metal chips, sawdust, or other debris from the cutting area, which keeps the saw running smoothly. Regular maintenance and replacement of coolant fluids are essential to ensure the system remains effective over time.

Motor and Drive System

The motor and drive system of a vertical band saw is responsible for providing the necessary power to operate the machine and control the cutting speed. The motor's power output is essential for determining the saw’s ability to cut through different materials. Metal cutting band saws generally require more power to cut through tougher materials, whereas wood cutting band saws may operate efficiently with less power, as wood is a softer material. The motor drives the saw blade via a drive system that consists of pulleys, belts, and gears.

Variable-speed drives are a key feature of modern band sawing machines, particularly CNC band saws. These drives allow the operator to adjust the cutting speed based on the material and the type of cut being made. Variable-speed controls ensure that the saw can operate efficiently across a wide range of materials, from softwoods to hard metals. This flexibility increases the saw’s versatility and ensures that it is always operating within optimal conditions for the material being processed. Regular maintenance of the motor and drive system is essential for prolonging the lifespan of the machine and ensuring smooth operation.

Applications of Vertical Band Sawing Machine

Metalworking

Vertical band saws play a crucial role in the metalworking industry, where precision and versatility are essential for cutting a variety of metal materials. These saws are widely used for cutting metal sheets, pipes, and profiles, making them an indispensable tool in factories and workshops that work with metal components. Whether it is for cutting thin sheets of metal or thick structural profiles, a vertical band saw is capable of handling different thicknesses and types of metal, including steel, aluminum, and alloys.

In metal cutting band saws, the blade design and cutting speed are critical factors in achieving high-quality cuts. These saws are equipped with specialized blades that can handle the specific demands of metal cutting, such as resistance to wear and heat buildup. The ability to cut through metals without causing excessive deformation or burrs is one of the reasons why metal cutting band saws are preferred in industrial settings. Additionally, CNC band saws are often used for more intricate metal cutting tasks, where precision and automation are required to meet the demanding specifications of the industry.

Woodworking

Woodworking is another key area where vertical band saws are frequently used, especially when creating curved shapes or resawing lumber. Wood cutting band saws are designed to handle a range of woodworking tasks, from cutting simple straight lines to intricate curves and patterns. The vertical design of the saw makes it particularly useful for cutting large pieces of wood, as it allows for greater flexibility and precision when performing detailed cuts.

In woodworking, the vertical band saw’s ability to create smooth, clean edges is essential for producing high-quality finished products. Whether it’s for furniture making, cabinetry, or decorative wood items, the vertical band saw provides the versatility needed for various cuts. Resawing lumber, a common woodworking task, involves cutting thick boards into thinner slices. The vertical band saw is well-suited for this purpose due to its ability to handle thick material and create uniform cuts. Furthermore, the narrow kerf of the saw blade reduces material wastage, making it an efficient choice for woodworking applications.

Aerospace

The aerospace industry requires highly specialized equipment to handle the unique materials and tolerances involved in the production of aircraft components. Vertical band sawing machines, particularly those equipped with metal cutting capabilities, are used to cut through materials such as aluminum, titanium, and composite materials used in aircraft construction. These materials often have specific properties, such as lightweight yet high strength, which require precise cutting to maintain their integrity.

In aerospace applications, precision is paramount, and CNC band saws are often used for tasks that require tight tolerances and intricate cuts. The ability of vertical band saws to handle complex geometries while maintaining accuracy makes them a critical tool in the manufacturing process. Furthermore, the saw's ability to cut a variety of materials—ranging from metals to advanced composites—makes it a versatile option for aerospace manufacturers. Whether cutting aluminum sheets or composite components, vertical band saws ensure the clean, accurate cuts required for the production of aircraft parts.

Automotive

In the automotive industry, vertical band saws are utilized for both prototyping and the manufacturing of various components. Whether cutting metal parts for engine blocks, frames, or interior components, these saws provide the precision necessary to meet the stringent quality standards of the automotive sector. Vertical band sawing machines are capable of handling a wide range of materials, including steel, aluminum, and plastic, all of which are common in automotive manufacturing.

The automotive industry often requires high-volume cutting, and vertical band saws are well-suited to this task due to their efficiency and speed. CNC band saws, in particular, are valuable for automating the cutting process, ensuring consistency and reducing the possibility of human error. Whether it's for prototyping new components or cutting parts for mass production, vertical band sawing machines offer the flexibility and precision needed to meet the demands of the automotive industry.

Applications Comparison Table

| Industry | Materials Cut | Key Applications | Type of Saw Used |

|---|---|---|---|

| Metalworking | Steel, Aluminum, Alloys | Cutting metal sheets, pipes, profiles | Metal Cutting Band Saw, CNC Band Saw |

| Woodworking | Hardwood, Softwood | Creating curved shapes, resawing lumber | Wood Cutting Band Saw |

| Aerospace | Aluminum, Titanium, Composites | Cutting aircraft components | Metal Cutting Band Saw, CNC Band Saw |

| Automotive | Steel, Aluminum, Plastics | Prototyping, manufacturing components | Metal Cutting Band Saw, CNC Band Saw |

Other Industries

Beyond the industries mentioned, vertical band saws have applications in various other fields, including manufacturing, construction, and even DIY workshops. Their versatility allows them to handle a wide range of materials, from plastics to textiles, making them a useful tool in industries where precise cutting and intricate shapes are required. For example, in construction, band saws are often used for cutting pipes, beams, and other structural materials, while in DIY or small-scale workshops, they can be used for crafting and creating customized items.

In addition, vertical band saws are sometimes used in the food industry, where they are employed to slice through meats, cheeses, or other materials that require precise, uniform cuts. These saws are designed to meet the strict hygiene standards required in the food industry, with easy-to-clean surfaces and blades that prevent contamination. The versatility of the vertical band saw, combined with its ability to cut a variety of materials, makes it a staple tool across many different sectors.

Advantages and Disadvantages of Vertical Band Sawing Machine

Advantages of Vertical Band Sawing Machine

Vertical band sawing machines are widely recognized for their versatility and ability to cut a variety of materials, making them an indispensable tool in many industries. One of the key advantages of a vertical band saw is its ability to handle materials such as metals, wood, plastics, and composites with ease. Whether it's cutting thick metal sheets or creating intricate shapes in wood, a vertical band saw can deliver precise and clean cuts. The wide range of materials it can cut, from softwoods to hard metals, makes it a highly adaptable tool that can meet the demands of different industries.

Another advantage of vertical band saws is their capacity for making intricate cuts. Unlike some other cutting machines, vertical band saws allow for the creation of detailed curves and complex shapes with relative ease. This is particularly useful in woodworking and metalworking applications where intricate designs are required. For example, in woodworking, a wood cutting band saw can be used to create smooth, curved cuts that would be difficult to achieve with a circular saw. The precision and control offered by vertical band saws make them a preferred choice for detailed work, particularly when combined with high-quality band saw blades and proper blade guides.

Efficiency in material usage is another significant advantage of vertical band saws. These saws generally produce a narrow kerf (the width of the cut), which means that less material is wasted compared to other cutting methods. This is especially important in industries like woodworking, where maximizing material yield is crucial. The precise cutting ability of vertical band saws ensures that the maximum amount of material is used, reducing scrap and making the cutting process more cost-effective. In addition, the vertical band saw's ability to cut a variety of materials with minimal waste enhances its overall efficiency, making it a valuable tool in both small and large-scale manufacturing settings.

Disadvantages of Vertical Band Sawing Machine

While vertical band saws offer numerous advantages, they also come with a few limitations. One of the primary drawbacks of a vertical band saw is its limited cutting depth compared to horizontal saws. Vertical band saws are typically designed for cutting thinner materials, and their cutting depth is often restricted by the height of the saw frame. This can be a disadvantage when working with larger or thicker materials that require deeper cuts. Horizontal saws, by contrast, offer greater cutting depths and are often preferred for cutting large pieces of material, such as heavy-duty metal beams or large logs. Therefore, if an application requires cutting through thick materials with a greater depth, a horizontal saw may be a more suitable option.

Another disadvantage is the higher initial cost associated with advanced models, particularly CNC band saws. While traditional vertical band saws are relatively affordable, the cost of a CNC band saw, which offers automated cutting and precision, can be significantly higher. CNC band saws are equipped with computerized controls that enable more precise and complex cutting operations, but the added technology and automation come at a higher price point. This initial investment may be a barrier for smaller businesses or workshops that cannot afford the upfront costs of these more advanced models. Additionally, the complexity of CNC band saws may require specialized training for operators, further increasing the overall cost of ownership.

Key Advantages and Disadvantages Comparison Table

| Advantages | Disadvantages |

|---|---|

| Versatility in cutting a variety of materials (metal, wood, plastic, etc.) | Limited cutting depth compared to horizontal saws |

| Ability to make intricate cuts and curves | Higher initial cost for CNC models |

| Efficient material usage with minimal waste | Requires regular maintenance to ensure optimal performance |

| Provides precision and control, especially with proper blade guides | Requires skilled operators, particularly for advanced models |

Additional Considerations

When considering the purchase of a vertical band sawing machine, there are a few additional factors that should be taken into account. For example, while the versatility and precision of these saws make them suitable for many applications, their effectiveness depends heavily on the quality of the band saw blades used. High-quality band saw blades, such as those designed specifically for metal cutting or wood cutting, can significantly improve the performance of the saw and extend its lifespan. Additionally, the choice of band saw guide plays a critical role in maintaining blade stability and accuracy during cutting, which is essential for achieving high-quality results.

Maintenance is another important consideration. While vertical band saws are relatively low-maintenance machines, regular care is required to ensure optimal performance. This includes checking and adjusting the blade tension, cleaning the work table, and ensuring that the coolant system is functioning correctly (if applicable). Regular inspections and maintenance help prevent issues such as blade misalignment or overheating, which can lead to reduced efficiency and increased wear on the machine. Operators should also be trained on how to properly operate the saw to minimize wear and ensure that the machine operates smoothly.

Another consideration is the type of vertical band saw to purchase. For basic tasks, a manual vertical band saw may be sufficient, but for more complex and high-volume operations, an electric or CNC vertical band saw may be more appropriate. CNC band saws, in particular, are ideal for precision cutting, as they provide automated control over the cutting process. These saws are capable of making highly detailed cuts without the need for constant operator input, making them ideal for industries that require mass production or intricate workpieces.