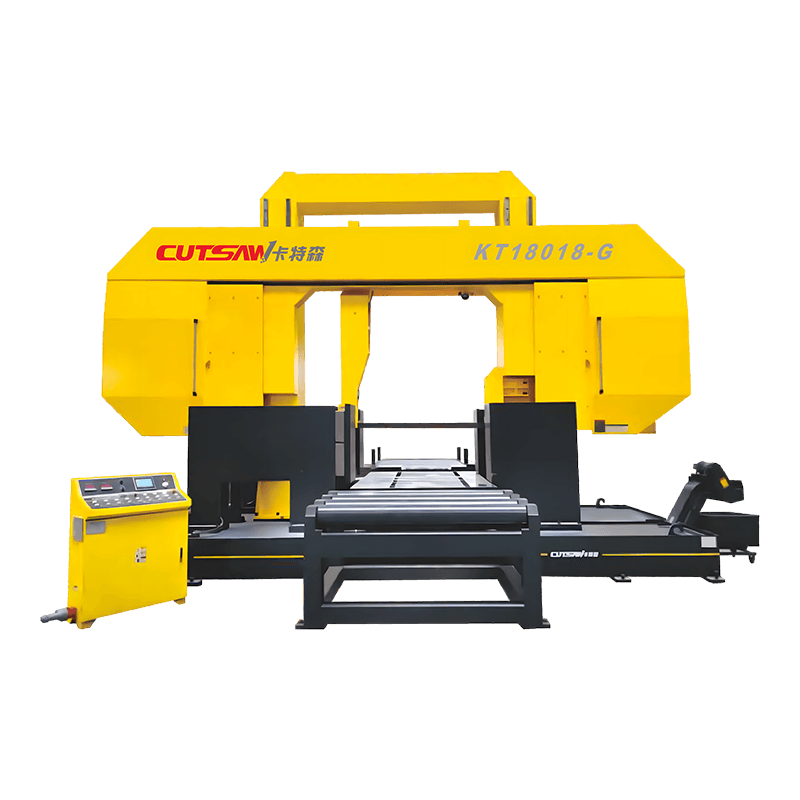

Introduction to Double Column Band Sawing Machines

The landscape of modern manufacturing is perpetually driven by the need for speed, precision, and the ability to process increasingly tough and complex materials. At the heart of this industrial capability lies a critical piece of equipment: the double column band saw machine. These formidable machines are not merely tools for slicing metal; they are engineering marvels designed to tackle the most demanding cutting operations with unwavering stability and accuracy. They represent the pinnacle of large-scale material separation technology, distinguishing themselves from simpler band sawing machine variants through a fundamentally superior architectural design. The demand for greater component size and the use of exotic materials, particularly in high-stakes sectors, has cemented the double column configuration as the gold standard for heavy-duty stock preparation.

Briefly define double column band sawing machines.

A double column band saw is defined primarily by its structural configuration. Unlike conventional or single-column saws where the saw frame is supported on only one side, the double column design features two robust, often vertical, columns or guides that rigidly support and guide the saw frame as it moves vertically or horizontally through the workpiece. This configuration, often featuring a heavy-duty, reinforced steel frame band saw construction, ensures that the cutting mechanism is held parallel and perpendicular to the material being cut throughout the entire stroke. This parallel guidance system is the key differentiator, providing maximal support, minimizing vibration, and ensuring linear accuracy, especially when dealing with massive blocks or bundles of material.

The foundational principle of any band sawing machine is the use of a continuous, toothed metal band—the blade—which runs over two large wheels, powered by a high-torque motor. This blade is tensioned to an extremely high degree, enabling it to slice through metal efficiently. However, in a standard or single-column setup, the cantilevered saw head can be susceptible to deflection or twisting forces when encountering the resistance of large, hard materials. The dual column band saw eliminates this vulnerability. By supporting the cutting head on two synchronized, precisely machined columns, the entire cutting force is distributed and perfectly controlled. This structural integrity allows the machine to apply necessary pressure without deviation, truly earning its place in the category of heavy-duty band saw equipment. The precision offered by this dual-support mechanism is non-negotiable for industries where material integrity and tight tolerances are paramount, often reducing the necessary machining allowance on the cut pieces.

The evolution from a basic single-post structure to the imposing double column band saw was driven by the metallurgical revolution of the 20th century. As stronger, tougher materials like high-carbon steels, heat-resistant alloys, and aerospace-grade composites emerged, the need for a stable and powerful means of preliminary cutting became critical. Early band sawing machine designs simply couldn't handle the scale and hardness of these new billets. The steel frame band saw with its double column structure provided the necessary resistance to torsion and bending, allowing for larger work envelopes and consistent straightness of cut. This rigidity is so crucial that the dimensional accuracy of the cut piece is often directly correlated with the machine’s structural stability, making the dual column design a fundamental requirement for modern, quality-focused manufacturing.

Highlight their importance in heavy-duty metal cutting.

The significance of double column band saw machines in the realm of heavy-duty metal cutting cannot be overstated. In demanding industries such as aerospace, automotive, shipbuilding, energy generation, and large-scale tool and die production, components are frequently forged or cast from high-strength alloys, specialized tool steels, and exotic materials like titanium, Inconel, and various nickel-based superalloys. These materials present significant operational challenges: they possess high yield strength, generate extreme thermal loads during cutting, and demand exceptional, unwavering feed force and structural stability to avoid premature blade wear, tooth chipping, or, most critically, inaccurate or non-perpendicular cuts.

This is precisely where the dual column band saw excels. Its superior rigidity allows for consistent, high-pressure feeding of the blade into the workpiece without the slightest hint of deflection or chatter. This vibration dampening capability is a massive advantage over less stable designs. When a blade chatters, the impact forces cause rapid micro-fracturing of the cutting edge, leading to quick dulling, increased heat generation, and a rougher cut surface. By ensuring a smooth, stable cut path, the heavy-duty band saw not only cuts faster but also drastically extends the functional life of the expensive bimetal or carbide-tipped blades.

The result is a transformative effect on production efficiency and cost-effectiveness. The stability allows for optimized parameters, such as higher feed rates and faster blade speeds, leading to faster throughput and significantly reduced processing time. For large metal service centers and high-volume component manufacturers, the ability to rapidly and accurately section large ingots or billets is directly tied to their profitability and delivery timelines. The investment in a robust industrial band saw with a steel frame band saw construction and a double column configuration translates directly into reduced material waste, superior component quality, and streamlined logistics. They are the workhorses responsible for breaking down huge raw material ingots and billets, which can weigh several tons, into manageable sections for subsequent CNC machining, forging, or heat treatment, making them a foundational element of the global manufacturing supply chain. Without the intrinsic stability of these machines, the cost and time associated with processing modern, high-performance materials would be prohibitive, potentially stalling innovation in sectors that rely on these advanced metallic compositions.

Mention the different types and applications.

The successful performance and widespread adoption of the double column band saw have led to several distinct categories and technological integrations, tailoring the core band sawing machine principle to a multitude of specialized industrial needs and workflow requirements. These distinctions primarily revolve around the orientation of the cut and the degree of automation incorporated into the machine's control system.

Categorization by Orientation:

Horizontal Double Column Band Saw: This is the most common and classic configuration for a dual column band saw. The saw frame is generally positioned horizontally, and the blade travels downwards into a horizontally clamped workpiece. This setup is perfectly suited for bulk cutting operations involving long bar stock, tubing, structural shapes, or massive rectangular and cylindrical billets. The horizontal arrangement allows gravity to assist the cutting process while the dual columns manage the substantial downward feed pressure required for effective metal cutting band saw operations on large diameters. They are the standard for metal service centers and primary material processing in almost every heavy industry.

Vertical Double Column Band Saw: While less common for high-volume, straight-line cutting of bar stock, the vertical configuration is indispensable for cutting large, thick plates, structural steel profiles, or for executing specialized contour or "slotting" cuts on workpieces. In this design, the workpiece often rests stationary on a table, and the blade assembly moves vertically along the columns, providing precision slicing for components where the material size prohibits movement. They are often used as a preliminary process to separate large plate material before it goes to plasma or laser cutting.

Categorization by Automation and Technology:

CNC Automatic Double Column Band Saw: The integration of Computer Numerical Control (CNC) has fundamentally transformed the capabilities of the double column band saw. A CNC band saw allows for fully automatic metal cutting. The operator programs the desired dimensions, cut sequence, and material type, and the machine manages the entire process: material indexing, clamping, cutting parameters, and material discharge. This level of automation is essential for high-volume, repetitive, and precision batch production. It ensures exceptional repeatability and drastically reduces the risk of operator error, allowing for complex nested cuts and optimized stock usage. The digital integration of the CNC band saw allows it to communicate with factory management systems (MES/ERP), enabling seamless integration into Industry 4.0 manufacturing ecosystems.

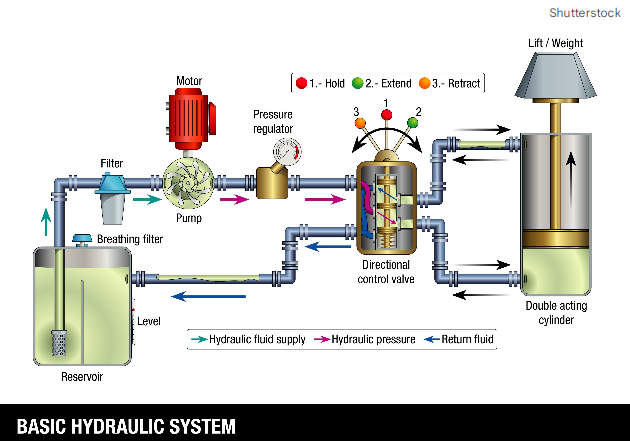

Hydraulic Double Column Band Saw: Although nearly all Heavy-Duty Dual Column Band Saw Machines utilize hydraulics for clamping and feeding, a specific emphasis on the hydraulic band saw highlights the crucial role this technology plays. Hydraulic systems are not just for brute force; they are critical for delivering smooth, finely controlled, and adjustable power delivery. This controlled power is essential for managing the varying resistance encountered when cutting different material cross-sections or transitioning between hard and softer material phases. Superior hydraulic dampening systems ensure a consistent, non-jerky feed rate, which is paramount for achieving a long blade life and a high-quality cut surface finish. A high-quality dual column band saw will always feature a sophisticated hydraulic system for precise, managed force application.

The expansive application landscape of the double column band saw speaks to its reliability and versatility. It spans critical processes such as preparing massive turbine shafts in the power generation industry, sectioning thick steel frames and armor plates for construction and defense projects, and slicing large aluminum and specialized steel sections for the rigorous demands of the aerospace industry. Furthermore, in the recycling and scrap processing sectors, the inherent stability and power of the industrial band saw configuration enable the rapid and efficient sectioning of large, difficult-to-handle components, contributing significantly to resource management. Their fundamental design ensures that they are not only used for rough cutting but also often employed in applications where the quality and squareness of the cut face are critical for subsequent high-precision machining steps, thereby minimizing the need for extensive post-cut finishing and maximizing downstream process efficiency. The combination of the rigid steel frame band saw structure and intelligent automation makes the modern double column band saw an indispensable asset.

What is a Double Column Band Sawing Machine?

The double column band saw is a specialized category of metal cutting band saw machines, designed explicitly to handle the rigorous demands of processing large-scale, high-density materials in modern manufacturing environments. To truly appreciate the advanced engineering of the double column design, one must first understand the foundational mechanics of the entire band sawing category. This machine represents a critical technological leap from conventional cutting methods, offering unparalleled stability and precision essential for today’s material challenges.

Explain the core functionality of band sawing machines

At its most fundamental level, a band sawing machine is a cutting device that employs a continuous, flexible loop of metal with teeth—the saw blade—stretched tightly between two or more wheels. This blade, moving in one continuous, linear direction, performs the cutting action. The core functionality is distinct from reciprocating saws or circular saws, offering several inherent advantages. The linear, continuous movement of the blade ensures that cutting is always performed by a fresh set of teeth, leading to highly efficient chip evacuation and significantly reduced heat generation per tooth. This smooth, uniform cutting action is essential for achieving a high-quality cut surface finish and maximizing blade life, particularly when dealing with tough alloys. The cutting speed and the feed rate are the two primary variables controlled by the operator or the machine’s CNC band saw system.

The fundamental process for all band saws involves securing the workpiece in a robust vise assembly and then feeding the continuous blade through the material until separation is achieved. In an industrial band saw, the massive power required to drive the blade at high speeds and maintain immense tension is delivered by a high-torque main motor. The overall efficiency of the cutting process is heavily reliant on the precision of the blade guides, which keep the narrow blade from twisting or deflecting under the heavy cutting load. This core functionality, when applied to heavy-duty band saw applications, demands a mechanism capable of managing enormous dynamic forces without compromising the geometric accuracy of the cut. This is where the structural rigidity of the double column configuration becomes not just beneficial, but absolutely indispensable. A standard single-column saw, designed for lighter duties, simply lacks the structural mass and guided support to maintain squareness when encountering a large, solid block of high-strength steel, often resulting in inaccurate, tapered, or non-perpendicular cuts that require expensive post-processing.

Detailed Explanation of Double column structure and its advantages

The double column structure is the defining characteristic and the paramount advantage of the modern metal cutting band saw designed for large stock. This architectural feature consists of two massive, vertically or horizontally oriented guide columns that form a stable, immovable frame. The saw head, which carries the drive and idler wheels, the blade, and the blade guides, is mounted and precisely guided along these two columns. This design principle achieves what single-column systems cannot: absolute, unwavering support for the cutting mechanism throughout the entire cutting stroke, regardless of the size or density of the material being processed.

The core advantage of this dual column band saw design is the elimination of deflection, twist, and vibration. In conventional single-column designs, the cutting head is cantilevered, meaning it extends out from a single point of support. When a heavy cutting load is applied, this cantilevered structure naturally wants to flex or twist away from the straight path. The double column band saw completely neutralizes this bending moment by distributing the reaction forces symmetrically across two widely spaced, highly rigid columns. This allows the machine to utilize much higher feed pressures and heavier blades necessary for heavy-duty band saw operations, especially on materials that are difficult to cut, such as nickel alloys or large titanium billets.

|

Feature |

Double Column Advantage |

Operational Benefit |

|---|---|---|

|

Structural Rigidity |

Symmetrical force distribution across dual guides. |

Eliminates saw head deflection and twisting under extreme load. |

|

Vibration Damping |

Massive, heavy-duty frame and dual-rail stability. |

Extends blade life by minimizing chatter, improves cut surface finish. |

|

Precision |

Constant, parallel guidance throughout the cutting stroke. |

Ensures superior cut squareness and perpendicularity (high tolerance). |

|

Feed Management |

Handles higher, consistent feed pressures without accuracy loss. |

Enables faster processing and increased throughput on tough, large materials. |

The rigidity provided by the steel frame band saw construction and the dual columns results in several measurable operational benefits. Firstly, it ensures superior cut perpendicularity, meaning the cut face is square to the stock within extremely tight tolerances, often better than 0.002 inches per inch of cut. Secondly, the damping of vibration extends the life of the blade dramatically, reducing costs and downtime associated with blade changes. Thirdly, the enhanced structural integrity allows for the integration of sophisticated automation and control systems. The feed rate, managed by a precision hydraulic band saw system, can be aggressively optimized because the machine structure can reliably handle the resultant forces. This synergy between the rigid structure and precise control enables truly efficient automatic metal cutting, making the CNC band saw variant of the double column machine the ultimate choice for high-volume, precision stock preparation. The reliability of this structure under continuous, heavy load is why the double column band saw remains the essential workhorse in sectors requiring continuous, high-precision material processing.

Explore its components and working principle.

The operational excellence of the double column band saw is a function of its specialized, integrated components working in synchronized harmony, all anchored by the rigid steel frame band saw structure. Understanding these components is key to appreciating the machine’s efficiency.

Key Components:

Saw Frame/Head: The main moving assembly, supported by the dual columns. It houses the entire blade drive system. Its stability on the columns is crucial for maintaining cutting accuracy.

Blade Drive System: Includes the main motor and reduction gearbox, which transmits high power to the drive wheel. The power output here determines the machine’s capacity for heavy-duty band saw operations.

Band Wheels: The drive wheel and the idler wheel around which the blade loops. These wheels must be perfectly balanced and aligned to minimize vibration and ensure smooth blade travel.

Blade Guides: Critical components located immediately adjacent to the cut area. They use carbide inserts or roller bearings to precisely stabilize the blade laterally and vertically just before it enters the material, ensuring the cut remains perfectly straight and perpendicular. Proper maintenance of the blade guides is vital for cut quality.

Vise and Clamping System: A robust, often hydraulically powered system that secures the workpiece. In a hydraulic band saw, the clamping pressure can be adjusted to prevent material movement without deforming softer materials. The precision of this system is integral to achieving repeatable results in automatic metal cutting.

Material Feed System: Typically an integral part of the CNC band saw. This system uses a hydraulic or servo-driven shuttle vise to accurately index the material forward after each cut, ensuring high repeatability for batch processing. This makes the horizontal band saw configuration highly productive.

Coolant System: Essential for heat management. It pumps high volumes of coolant/lubricant directly into the cutting zone to reduce friction, flush chips, and prevent thermal damage to both the blade and the workpiece.

Working Principle:

The process is initiated by the CNC band saw control system, which manages the entire cutting cycle. First, the material is positioned by the shuttle vise and rigidly clamped by the hydraulic band saw vise system. Once clamped, the main motor accelerates the blade to the programmed speed (SFM), which is determined by the material type and blade characteristics. The core of the operation lies in the controlled, synchronized downward feed of the saw frame along the two columns.

The double column band saw uses a finely controlled hydraulic cylinder to regulate the feed rate. Unlike a constant weight feed, the hydraulic system allows for instantaneous adjustments to the feed pressure based on the resistance encountered by the blade. This ability to "listen" to the blade and regulate feed force is crucial for optimizing the cut on inconsistent or variable materials. The rigidity of the dual column band saw structure ensures that all the hydraulic force translates directly into cutting effort, maintaining the blade's precise angle of entry and exit. As the blade penetrates the material, the coolant system bathes the cut, ensuring rapid chip evacuation and optimal cutting temperature. Upon completion of the cut, the hydraulic system raises the saw frame quickly, the vise unclamps, the material feed system indexes the stock forward to the next programmed length, and the cycle repeats. This fully integrated and precise operation distinguishes the double column band saw as the premier industrial band saw solution for heavy-duty metal cutting.

Types of Double Column Band Sawing Machines

The foundational design of the double column band saw serves as a robust platform for numerous specialized machine configurations. These variations are engineered to meet specific manufacturing demands, primarily concerning the orientation of the workpiece and the level of automation required for the production workflow. While the core principle of dual column band saw support remains constant, the mechanical and electronic integrations define the machine’s optimal application, ranging from high-volume, straight-cut processing to complex, automated operations. Understanding these types is crucial for any operator or procurement specialist seeking the most efficient industrial band saw solution for their particular metal cutting band saw needs.

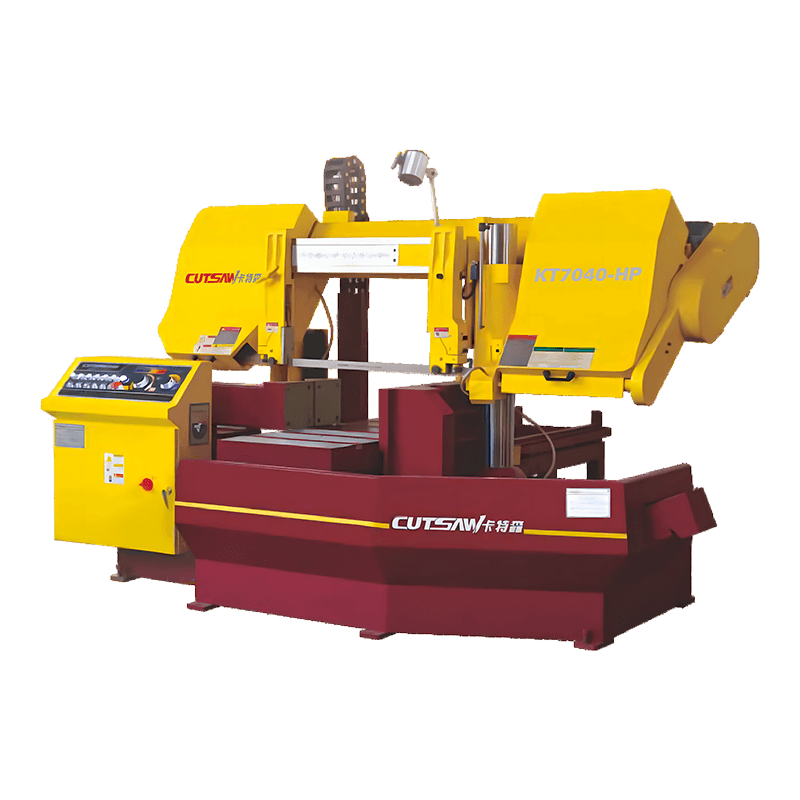

Horizontal Double Column Band Saw Machines

The horizontal band saw configuration is arguably the most prevalent and recognizable form of the double column band saw in material processing centers worldwide. Its architecture is explicitly designed for the continuous, high-volume sectioning of long, straight raw materials, such as bar stock, tubing, structural beams, and large diameter round or rectangular billets. In this configuration, the workpiece is clamped horizontally, and the saw head, guided by the twin columns, feeds vertically through the material. This orientation is highly effective because it allows the massive weight of the saw head and the cutting forces to be symmetrically applied and precisely controlled, ensuring a perfectly perpendicular cut face.

The stability inherent in the steel frame band saw construction of the horizontal band saw is critical when performing automatic metal cutting on large, tough pieces. As the blade penetrates a thick cross-section of high-alloy steel, the cutting resistance can be immense. The twin column guides prevent the twisting or deflection that would otherwise compromise the squareness of the cut, which is essential for minimizing downstream machining time. Furthermore, the horizontal design easily integrates with complex material handling systems. In many modern facilities, the machine is coupled with powered roller conveyors, automatic loading decks, and automated scrap removal systems, creating a fully continuous workflow ideal for high-throughput batch cutting. This arrangement is the backbone of metal service centers, forging plants, and major automotive component suppliers where efficiency and cut accuracy are measured across thousands of repetitions. The robust nature of these Heavy-Duty Dual Column Band Saw Machine means they can accommodate extremely wide blades capable of applying high feed pressure, maximizing material removal rates. They represent the optimal balance between brute force cutting power and micron-level guided precision, a necessary combination for serious industrial production.

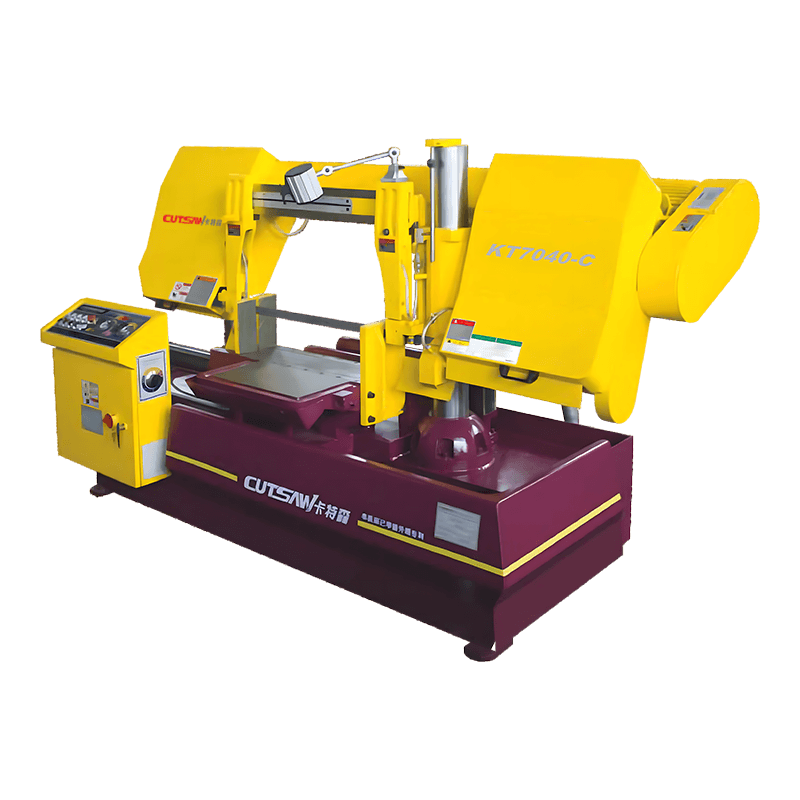

Vertical Double Column Band Saw Machines

In contrast to its horizontal counterpart, the Vertical Double Column Band Saw is optimized for applications where the material cannot be easily indexed or is best cut while resting flat. This type of double column band saw features a stationary work table where the material is secured. The saw head, mounted vertically between the dual columns, then travels downward or across the plane of the material. This configuration is often employed for cutting extremely large or unwieldy materials, such as thick metal plates, massive structural shapes, or for performing specific slotting or notching operations. The key advantage here is the material’s stable position. Since the workpiece remains immobile and supported over a large surface area, vibration is minimized, and the cutting forces are absorbed into the foundation.

While the majority of high-volume automatic metal cutting is done horizontally, the vertical setup is indispensable in specialized fields. For instance, in tool and die manufacturing, where large, expensive blocks of tool steel must be cut to create blank forms, the vertical orientation ensures the highest degree of structural stability during the separation of vast material cross-sections. In the aerospace industry, cutting large, complex forgings from challenging superalloys often requires the unique handling capabilities of a heavy-duty band saw in a vertical configuration. Although these machines may not offer the same raw throughput speed as a horizontal band saw on bar stock, their structural integrity and ability to handle material width and height make them invaluable. The vertical dual column band saw provides the essential rigidity for precise cuts on material sizes that would simply overwhelm lesser machines, securing its position as a specialized, essential industrial band saw tool.

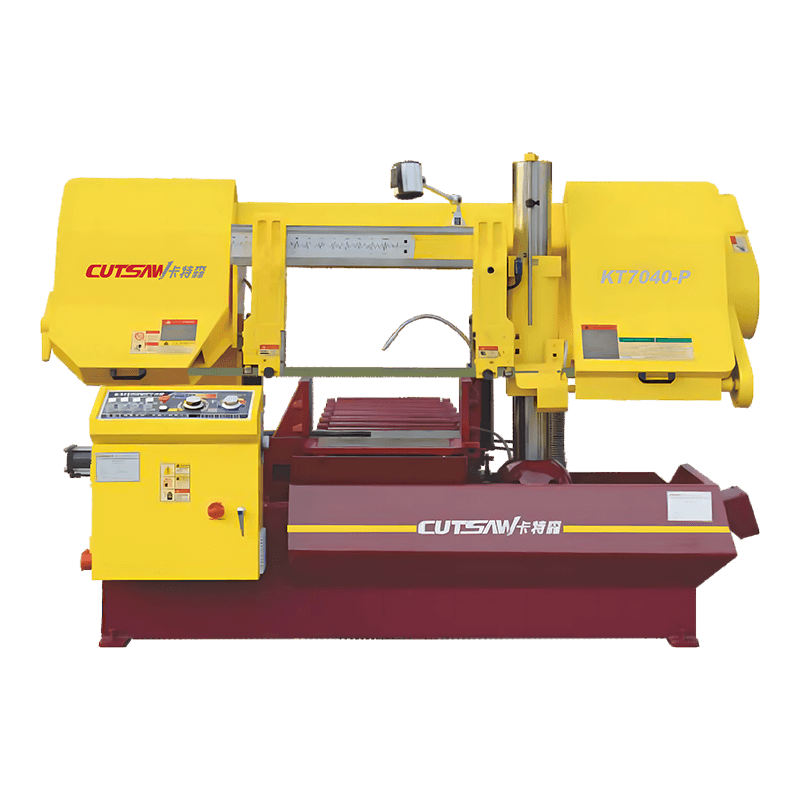

CNC Automatic Double Column Band Saw Machines

The integration of Computer Numerical Control (CNC) technology transforms the double column band saw from a powerful mechanical tool into a sophisticated, intelligent production unit. The CNC band saw is designed for maximum efficiency, minimizing manual intervention and maximizing repeatability. The "automatic" descriptor signifies that the entire sequence—from material feeding and clamping to cutting, blade retraction, and re-feeding—is executed autonomously under the precise command of a programmed controller. This control system allows the operator to input parameters such as cut length, batch quantity, material grade, and even preferred chip-load, enabling the machine to dynamically adjust its speed and feed rates throughout the cut.

The precision of the dual column band saw structure is the perfect complement to CNC automation. Because the machine’s physical structure is inherently rigid, the microscopic commands from the CNC controller are accurately translated into physical movement without deflection. This means the CNC band saw can achieve cutting accuracies and repeatability far beyond what is possible with manual or semi-automatic controls. Key features include servo-driven shuttle vises for extremely accurate material indexing, diagnostic systems that monitor blade tension and motor load, and advanced software for optimizing nested cuts or material yield. For facilities involved in high-volume production of identical parts, such as fasteners, hydraulic components, or bushings, the CNC band saw is mandatory. It facilitates true automatic metal cutting, ensuring every part in a batch of thousands is cut to the same tight tolerance, thereby significantly reducing waste and subsequent machining time. This level of automation is what distinguishes a modern industrial band saw and allows it to integrate seamlessly with automated material resource planning (MRP) and enterprise resource planning (ERP) systems, pushing manufacturing closer to the Industry 4.0 ideal.

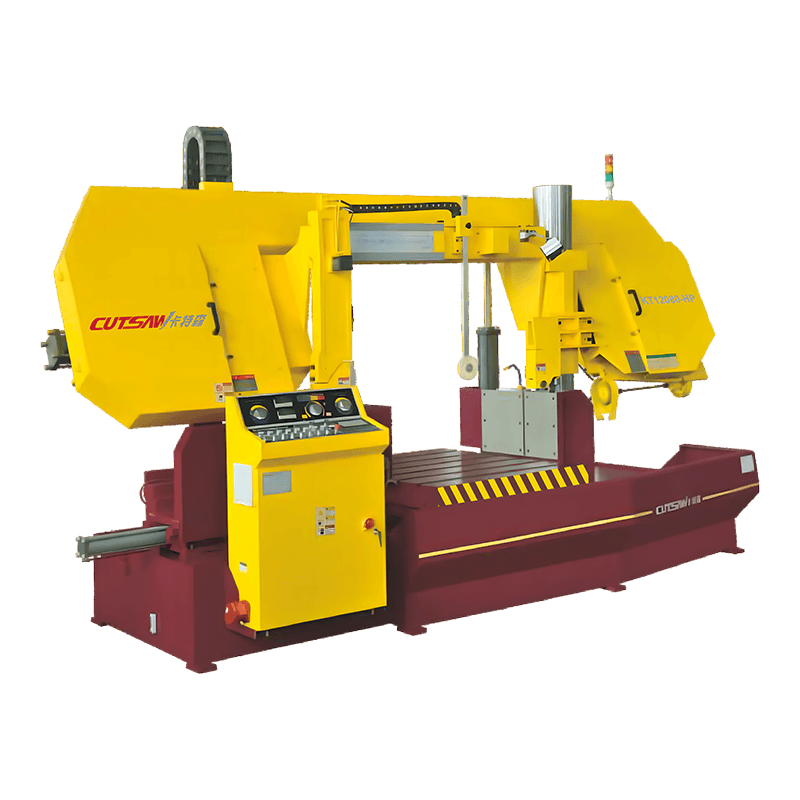

Hydraulic Double Column Band Saw Machines

While all Heavy-Duty Dual Column Band Saw Machine utilize hydraulic power for key functions like clamping and material indexing, the term hydraulic band saw often emphasizes the sophisticated role of the hydraulic system in controlling the feed rate of the saw head. This is the mechanism responsible for delivering the cutting force. In a premium double column band saw, the hydraulic system is far more than just a source of brute force; it is a highly refined system of proportional valves, pressure transducers, and dampeners that govern the downward movement of the saw head with extreme subtlety.

This nuanced control is vital because the cutting characteristics of metal change constantly. The resistance is high when the blade first enters the material, and it changes dramatically as the blade progresses through a variable cross-section. A precision hydraulic band saw system, often coupled with the feedback loop of a CNC band saw, can instantly adjust the feed pressure to maintain an optimal chip load on the blade teeth. This prevents both overloading and underloading. The fluid, damped movement provided by the hydraulic system ensures a smooth, consistent cut, which is essential for minimizing vibration and extending the life of high-cost carbide blades used in serious metal cutting band saw operations. Furthermore, the hydraulic system powers the robust clamping mechanism, ensuring the material is held immovably during the aggressive cutting process, which is necessary for the steel frame band saw to deliver its maximum potential. The reliability and smooth power transmission of the hydraulic band saw system are foundational to achieving the high-precision results expected from any modern dual column band saw dedicated to high-performance cutting. The synergy between the physical rigidity and the hydraulic control defines the ultimate capability of the modern industrial band saw.

|

Type of Double Column Band Saw |

Primary Purpose |

Key Mechanism |

Ideal Application |

|---|---|---|---|

|

Horizontal |

High-volume, straight cutting of long stock. |

Saw head moves vertically down through horizontally clamped material. |

Metal service centers, bar stock preparation, high-volume batch cutting. |

|

Vertical |

Cutting large plates, structural shapes, or complex geometries. |

Saw head moves vertically along the columns across stationary material. |

Tool and die blanks, large structural element slicing, aerospace forgings. |

|

CNC Automatic |

Unmanned, highly repeatable batch processing. |

Computer Numerical Control manages material indexing, cutting parameters, and cycling. |

Mass production of component blanks. |

|

Hydraulic |

Precision management of cutting force and feed rate. |

Proportional hydraulic valves control saw head feed based on real-time blade load feedback. |

Cutting difficult, large-diameter, or variable-hardness alloys |

Key Features to Consider for Heavy-Duty Double Column Band Saws

When investing in a double column band saw prospective buyers must look beyond mere size and horsepower. The true value and efficiency of a dual column band saw reside in the synergistic interaction of its integrated features. These characteristics determine the machine's true capacity for automatic metal cutting, its sustained precision, and its overall operational longevity in a demanding heavy-duty band saw environment. Selecting the right combination of features ensures the machine aligns perfectly with the manufacturing workflow, material characteristics, and desired production volumes.

Cutting Capacity

Cutting capacity is the primary specification that defines a double column band saw and must be rigorously evaluated. This metric is defined by the maximum dimensions that the machine can physically accommodate and cut. The capacity is directly related to the distance between the two supporting columns and the vertical travel limits of the saw head. Because of the inherent rigidity provided by the two columns and the massive steel frame band saw construction, these machines are explicitly designed to handle billets, forgings, and bundles that would be structurally impossible for single-column saws to process accurately.

In industrial band saw applications, capacity is not just about physical size; it’s about maintaining accuracy over that maximum dimension. A machine with a 30-inch capacity must deliver a cut face that is perpendicular and flat across the entire 30 inches. This requires the extreme resistance to deflection that only the dual column band saw architecture can offer. Furthermore, the maximum cutting capacity often dictates the required power of the blade drive motor and the corresponding size of the blade. A larger capacity machine requires a wider, thicker blade to maintain stability, demanding more robust motor power and a stronger drivetrain to handle the increased cutting load and frictional resistance. When evaluating models, it is essential to consider the actual working envelope not just the theoretical maximum clearance. Oversizing capacity slightly can also provide valuable flexibility for future material requirements or odd-shaped stock preparation.

Blade Speed

Blade speed, typically measured in Surface Feet per Minute (SFM) or meters per minute, is a crucial parameter that determines cutting efficiency and the longevity of the blade. This feature must be adjustable and precisely controlled because the optimal cutting speed varies dramatically based on the material's hardness, composition, and thermal properties. For instance, soft materials like aluminum and non-ferrous alloys require high SFM to achieve efficient chip formation, while tough, heat-resistant materials like tool steels, titanium, and nickel superalloys demand significantly slower, more controlled speeds to prevent excessive heat buildup, micro-welding, and premature blade wear.

Modern CNC band saw machines utilize advanced Variable Frequency Drives (VFDs) integrated into the main motor control. This allows for instantaneous, stepless adjustment of the blade speed, enabling the operator to fine-tune the SFM for the exact alloy being cut. Superior metal cutting band saw models also feature closed-loop feedback, where the control system can monitor the load on the motor and adjust the SFM to maintain optimal performance, especially when transitioning between the center and edge of a large billet where cutting conditions change. The ability to precisely match the blade speed to the cutting resistance is foundational to maximizing blade life and reducing overall cutting time, making this feature a key component of efficient and cost-effective automatic metal cutting.

Blade Size

The specifications of the saw blade are intrinsically linked to the machine's structural capability and cutting performance. In a double column band saw, the structural rigidity allows for the use of wider and thicker blades, often exceeding 2 inches in width. Blade width is directly proportional to its beam strength; a wider blade is more resistant to the lateral forces that cause twisting and deflection during a deep cut. This is vital for maintaining the perpendicularity of the cut across large cross-sections.

The width and thickness of the blade are determined by the machine manufacturer and must be adhered to. Running a blade that is too narrow for a given machine and application will result in poor cut geometry and rapid failure, even on a dual column band saw. Furthermore, the choice between bimetal and solid carbide blades is dictated by the materials being cut. Carbide-tipped blades, necessary for extreme heavy-duty band saw applications on superalloys, require the ultimate stability provided by the steel frame band saw structure and precise blade guides. A quality industrial band saw will feature highly adjustable, robust blade guides located close to the material, ensuring that the wide, high-tension blade is stabilized just meters before entry, maximizing cutting accuracy and minimizing the micro-vibrations that degrade cut quality.

Coolant System

The coolant system is far more than a simple pump; it is a critical thermal management and chip evacuation system essential for efficient metal cutting band saw operations. Its primary functions are:

Cooling: Removing frictional heat from the cutting zone, which prevents metallurgical damage to the workpiece and preserves the hardness of the blade teeth.

Lubrication: Reducing friction between the blade and the material, thereby reducing power consumption and heat.

Chip Flushing: Aggressively washing chips away from the kerf (the cut slot), preventing re-cutting of chips which drastically reduces blade life and cutting efficiency.

A high-performance double column band saw will incorporate a high-volume, often dual-nozzle, flood coolant system that ensures the fluid reaches the deepest part of the cut. More advanced systems, especially those supporting automatic metal cutting, include chip conveyor systems that automatically remove the swarf from the machine basin and deposit them into an external collection bin. This continuous chip removal is mandatory for unmanned operation and prevents chips from clogging the cutting zone or damaging the hydraulic components. The integration of a CNC band saw can also automate the mixing and monitoring of the coolant/lubricant concentration, ensuring optimal performance for different materials being processed.

Hydraulic System

The hydraulic system is the very heart of the hydraulic band saw's operational control and power delivery. Its significance in a dual column band saw cannot be overstated, as it governs three critical areas: clamping, material feeding, and saw head feed control. For the cutting process itself, the hydraulic system manages the downward movement of the saw head and thus the feed pressure applied to the blade.

In premium models, the system features proportional hydraulic valves and pressure sensors that operate in a closed-loop with the CNC controller. This allows the system to instantaneously adjust the feed rate based on the real-time resistance the blade encounters. This intelligent control ensures a constant, optimal chip load, a principle known as constant downfeed pressure regulation. This finesse in power delivery is crucial for preventing the blade from "biting" too hard when starting a cut or stalling when encountering a particularly hard section. The smooth, damped action provided by a well-designed hydraulic band saw system minimizes structural shock and vibration, directly contributing to superior cut finish and extended tool life. Furthermore, the powerful hydraulic vises ensure the material remains absolutely fixed, essential for maintaining accuracy during aggressive heavy-duty band saw cutting cycles.

CNC Control

The Computer Numerical Control (CNC) system elevates the modern double column band saw to a true automated manufacturing platform. The CNC band saw is defined by its ability to execute complex cutting programs automatically, reducing reliance on constant operator oversight. A robust CNC controller offers a user-friendly interface for programming batch jobs, including multiple cut lengths from a single piece of stock, and managing material remnants efficiently.

Key capabilities of the CNC system include:

Parameter Optimization: Storing and retrieving cutting parameters for hundreds of different materials and blade combinations.

Diagnostic Feedback: Monitoring critical operational parameters such as blade tension, motor load, and coolant levels, and automatically stopping the machine if unsafe conditions are detected.

Material Indexing: Controlling the servo or hydraulic shuttle vise to index the material forward with micron-level accuracy, ensuring tight tolerances in automatic metal cutting.

Networking: Integrating the industrial band saw into the factory network, allowing for remote monitoring, performance data collection, and integration with inventory and production scheduling systems.

The intelligence of the CNC band saw ensures high repeatability and minimal scrap generation, making the machine a highly efficient component of any modern steel frame band saw based metal processing facility.

Material Clamping System

The material clamping system is the foundation of cutting accuracy. No matter how rigid the double column band saw frame is, if the material moves during the cut, the finished piece will be inaccurate. Therefore, the clamping system must be exceptionally robust, stable, and precisely controlled. In a heavy-duty band saw, this system is almost universally hydraulic, providing massive clamping force.

Key components include the fixed vise and the shuttle vise. The shuttle vise is crucial for automatic metal cutting and acts as the material feeder, accurately moving the stock forward after each cut. The vise jaws should be designed to clamp the material on all sides, ensuring stability, especially when cutting bundled material or odd shapes. Modern systems often include split-vise capabilities, allowing the vise to open only partially to manage the final material remnant more efficiently, thereby minimizing material waste. The integrity of the clamping system is what ultimately translates the mechanical power into a precise and repeatable cut, cementing the machine’s role as a high-precision metal cutting band saw. The clamping force and positioning accuracy must be proportional to the overall cutting capacity of the dual column band saw.