After use, the circular saw may cause uneven cuts, and some machines may even have slight deformation and rough edges. How should we solve the above problems? Next, we will analyze the reasons one by one for you.

Generally speaking, uneven cutters are process problems. From the source, the metal circular saw may have a failure. We can check whether the fixtures of the equipment are too close or too loose. If the fixtures are excluded, then look at the saw blade. If there is a problem with the saw blade, there will be a gap that will also lead to uneven wide cuts of the workpiece. When both of the above situations are fine, then it is very likely that the circular saw itself is insufficient power, resulting in insufficient cutting speed, and the problems of uneven cutters, burrs and slight deformation.

A brief list of some reasons, you can check it in order. In fact, it is a bit troublesome to completely solve this problem. In the industry, it is generally necessary to replace equipment or process it again. No matter how it is done, it will increase the company's cost and slow down production efficiency. We should carry out better maintenance and maintenance during normal use, so as to greatly avoid the problem of uneven cutting of metal circular saws.

Mechanical equipment is like humans. As long as it is produced, problems will occur over time. Whether it is a production company or a processing factory, what we need to do is start from the details, treat the circular saw machine well, maximize its value, and contribute to the enterprise.

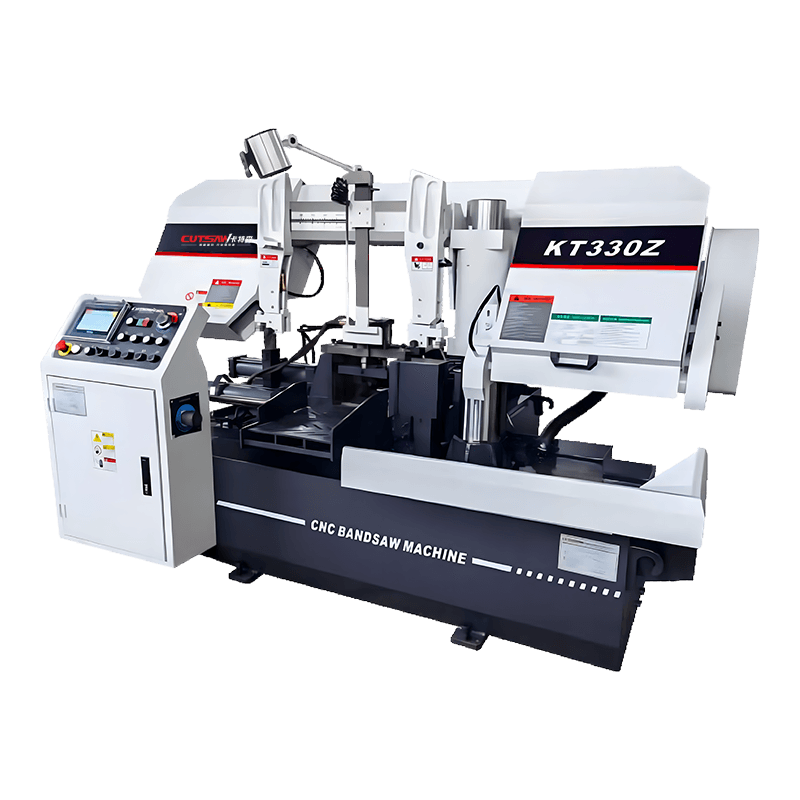

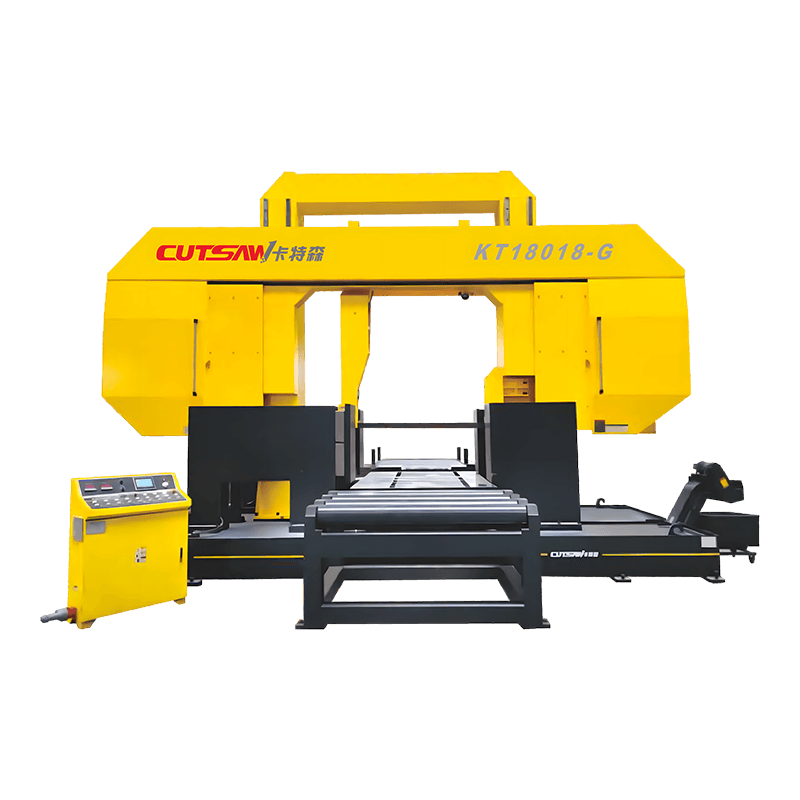

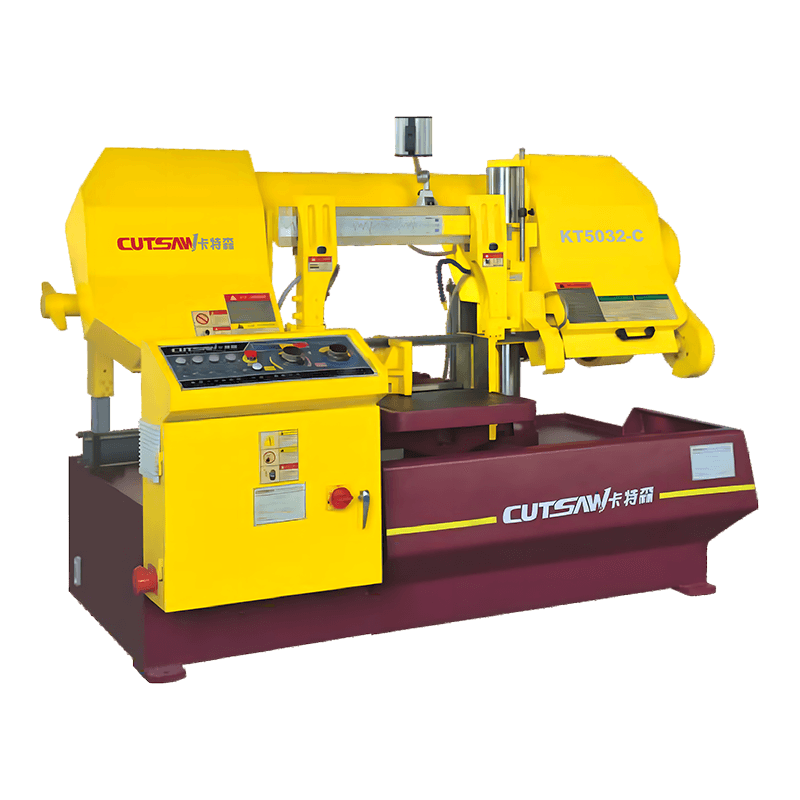

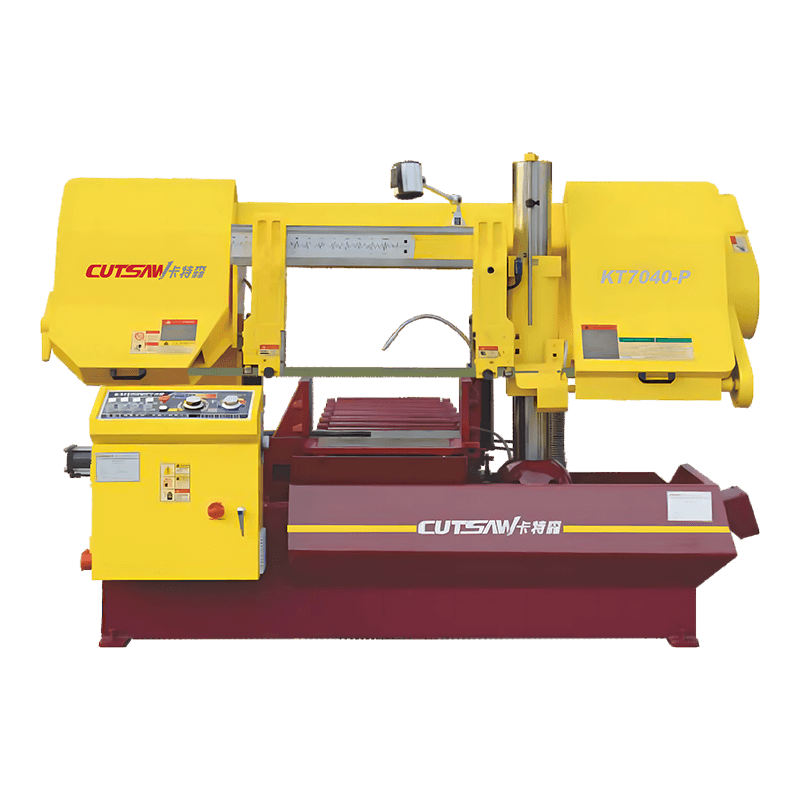

Characteristic description ● Bed mechanism: one cast bed, secondary aging stress relief, high stability, high precision, good seismic performance; ● Wide sawing range, compact design, 35-735 width saw...

See Details