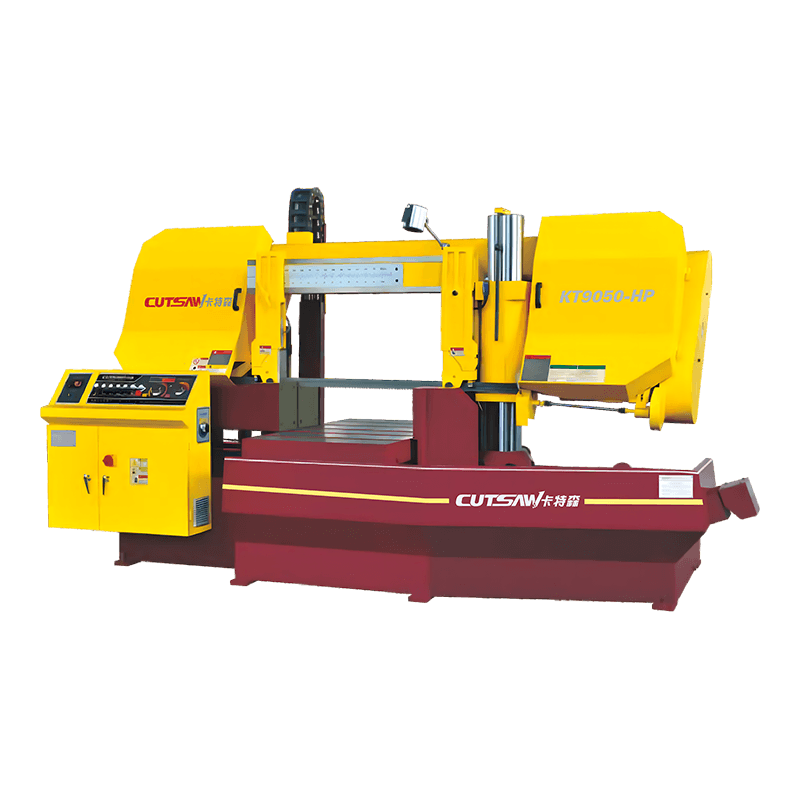

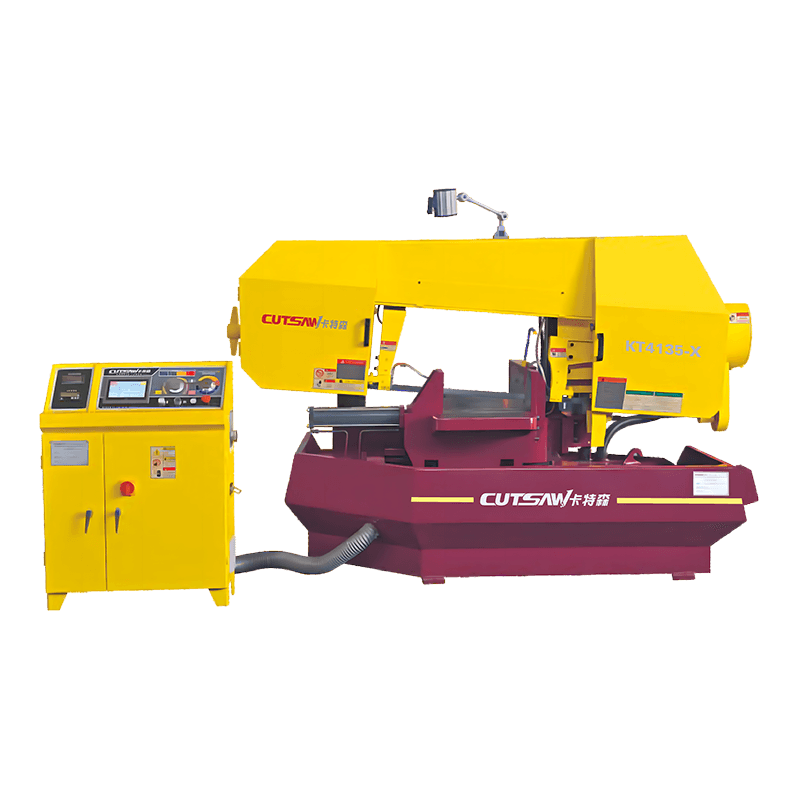

Automated Operation and Precision Control

The CNC Band Sawing Machine distinguishes itself from manual or conventional band saws primarily through its computer-controlled operation. This automation allows for precise, consistent cutting without the variability inherent in manual operation. Advanced CNC systems control the blade speed, feed rate, and cutting angle, ensuring that even complex or angled cuts are executed with high accuracy and minimal deviation. Unlike traditional band saws that rely heavily on operator skill and constant manual adjustments, CNC band saws maintain uniform quality across multiple cuts, which is essential for precision-driven applications such as metal fabrication, aerospace components, and custom engineering parts. The ability to control every aspect of the cutting process through programming ensures superior results and reduces the likelihood of errors.

Programmable Cutting and Repeatability

A core advantage of the CNC Band Sawing Machine is its programmable functionality, which allows operators to input exact dimensions, cutting sequences, and angles into the machine’s control system. Once programmed, the machine can perform repetitive cuts with identical accuracy, eliminating the variability and inconsistency associated with manual sawing. This repeatability is particularly valuable in batch production environments, where hundreds or thousands of identical components are required. By automating repetitive tasks, CNC band saws not only improve product consistency but also reduce material waste and labor costs, ensuring a more efficient and predictable production workflow.

Material Versatility and Optimized Cutting

CNC Band Sawing Machines are engineered to handle a wide range of materials, including carbon steel, stainless steel, aluminum, non-ferrous metals, plastics, and composites. Features such as variable blade speed, adjustable feed rates, and automated blade tensioning allow the operator to optimize the cutting parameters for each material type, ensuring smooth cuts and prolonging the lifespan of blades. Unlike conventional band saws, which may require repeated adjustments and careful manual handling to avoid uneven cuts or blade damage, CNC systems automatically adapt to material differences, resulting in efficient, high-quality cuts regardless of material hardness or thickness.

Integrated Safety Features

Safety is a critical differentiator of CNC Band Sawing Machines. These machines often include automated material clamping, blade guards, emergency stop systems, and sensors that detect abnormal blade movement or excessive vibration. By reducing the need for manual handling of materials near moving blades, the CNC system significantly minimizes the risk of operator injury. In contrast, conventional and manual band saws require constant manual involvement, increasing exposure to sharp blades and operational hazards. CNC machines may incorporate interlocked safety doors and protective shields, ensuring compliance with industrial safety standards and providing operators with a secure working environment.

Efficiency and Time-Saving Capabilities

CNC Band Sawing Machines greatly enhance production efficiency compared to manual or conventional saws. Automated feeding and cutting cycles allow the machine to operate continuously with minimal supervision, drastically reducing the time required for repetitive cuts. Features such as automatic blade tensioning, lubrication systems, and optimized cutting sequences reduce downtime and blade wear, enabling the machine to maintain high-speed operation without compromising quality. The result is a significant increase in throughput, particularly in industrial settings where large volumes of material need to be processed quickly and accurately, giving manufacturers a competitive advantage in productivity.

Advanced Monitoring and Diagnostics

Modern CNC Band Sawing Machines often include real-time monitoring and diagnostic tools, allowing operators to track blade condition, machine performance, and operational parameters. This capability enables predictive maintenance, alerting users to potential issues before they result in costly downtime or compromised cuts. Conventional band saws lack this level of oversight, relying entirely on operator experience to detect wear or mechanical issues. By providing data on performance trends, blade wear, and system efficiency, CNC machines help ensure consistent quality, extended blade life, and reduced maintenance costs, contributing to smoother production processes and more reliable operations.