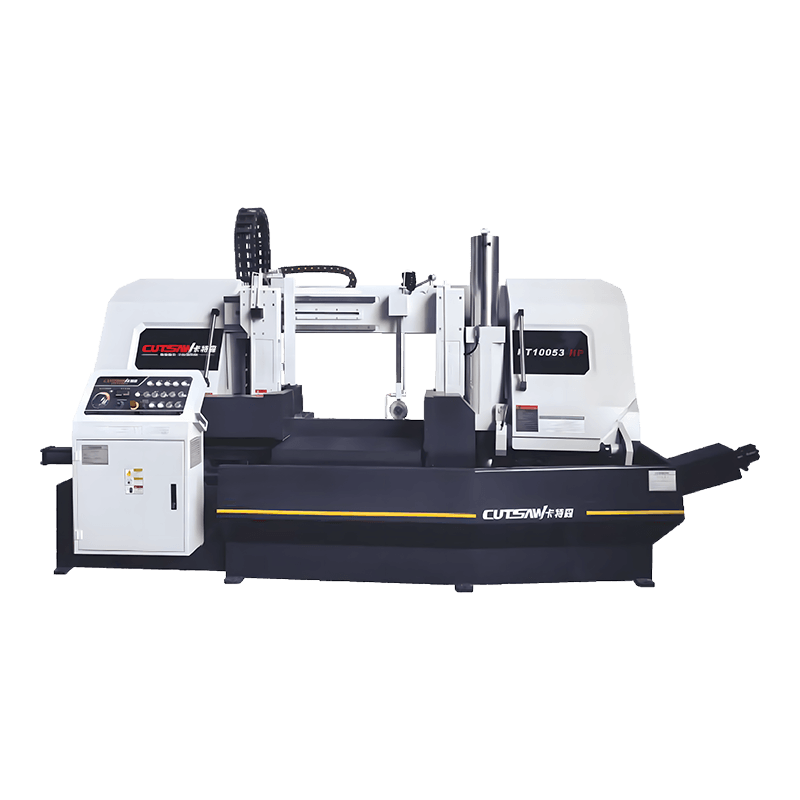

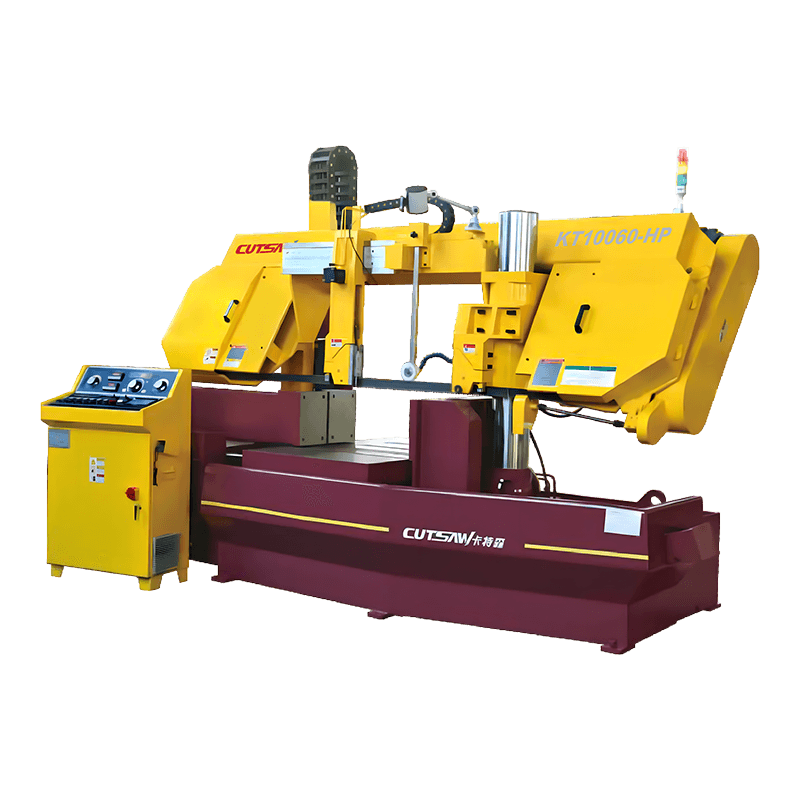

Our Company is China KT10053-HP Semi Automatic Metal Cutting Band Saw Machine Manufacturers and KT10053-HP Semi Automatic Metal Cutting Band Saw Machine Factory. SINAIDA CNC sawing machines support China’s aerospace industry and are recognized as a qualified supplier by the China Academy of Launch Vehicle Technology.

Zhejiang SINAIDA Machine Tools Co., Ltd. was established on December 8, 2000, and is located at No. 152 Xinggong Road, Huzhen Town Industrial Park, Jinyun County, Lishui City, Zhejiang Province. It is a national high-tech enterprise and a provincially recognized innovative enterprise. The company has an excellent management and R&D team, strong technical capabilities, well-equipped facilities, and advanced production technology.

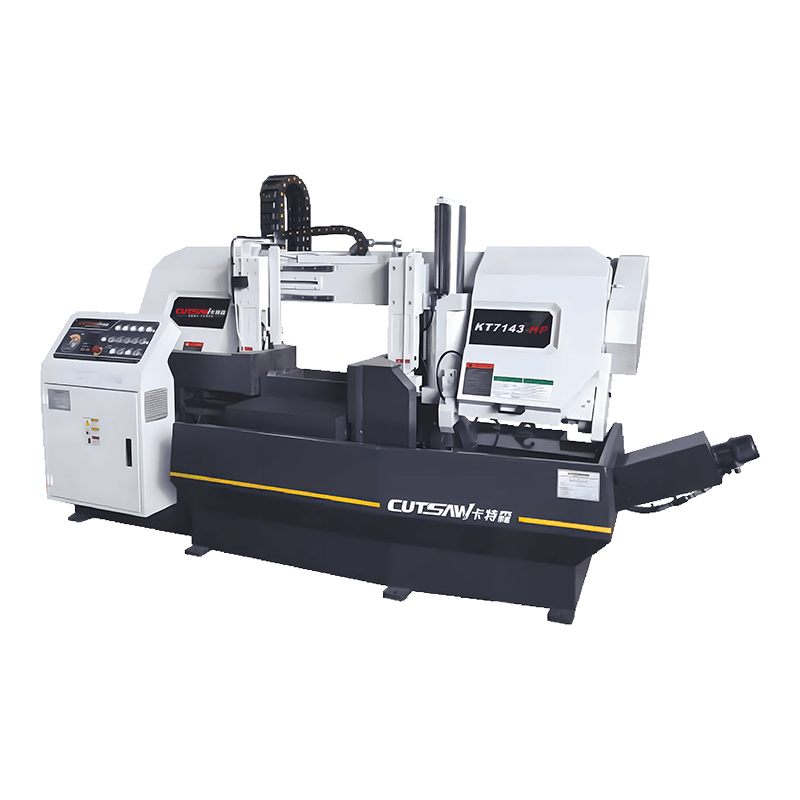

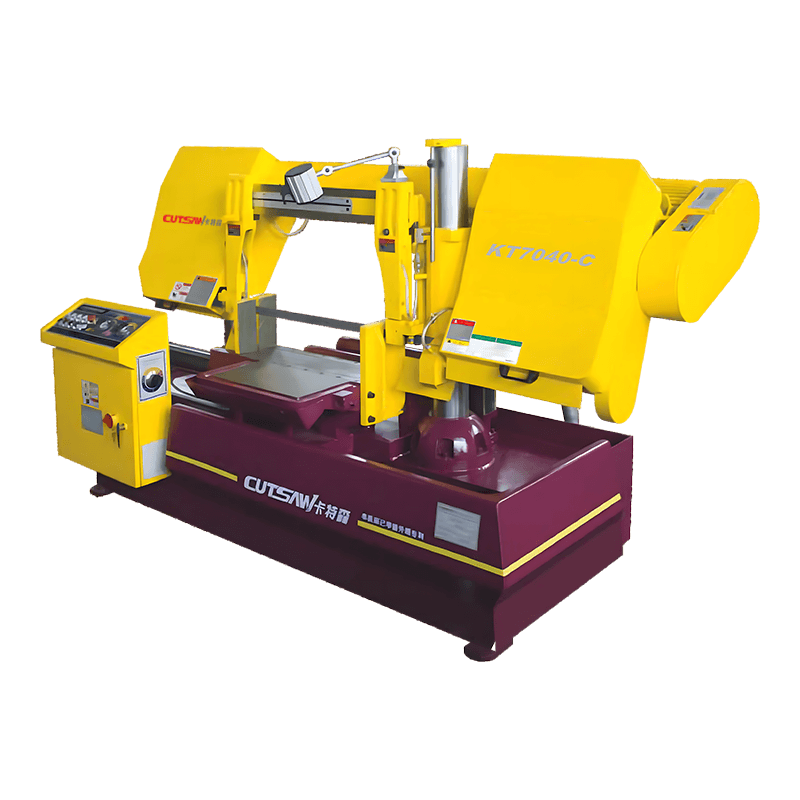

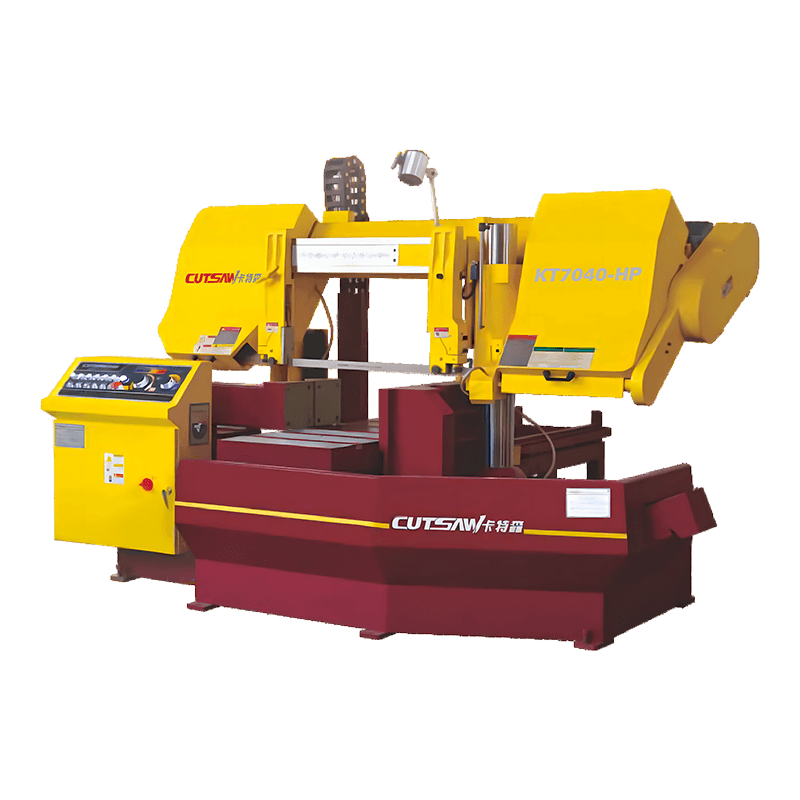

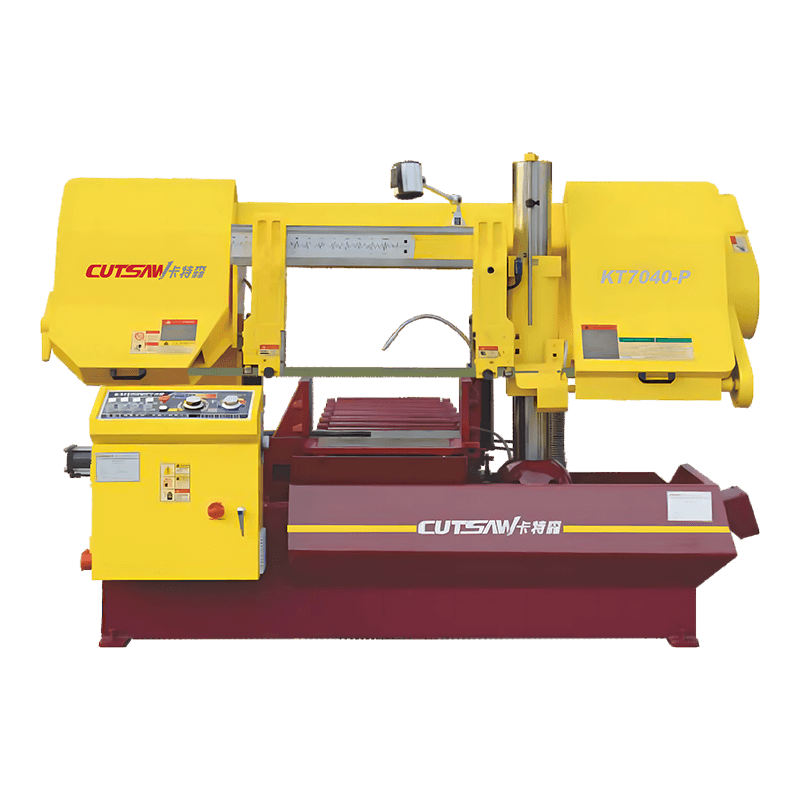

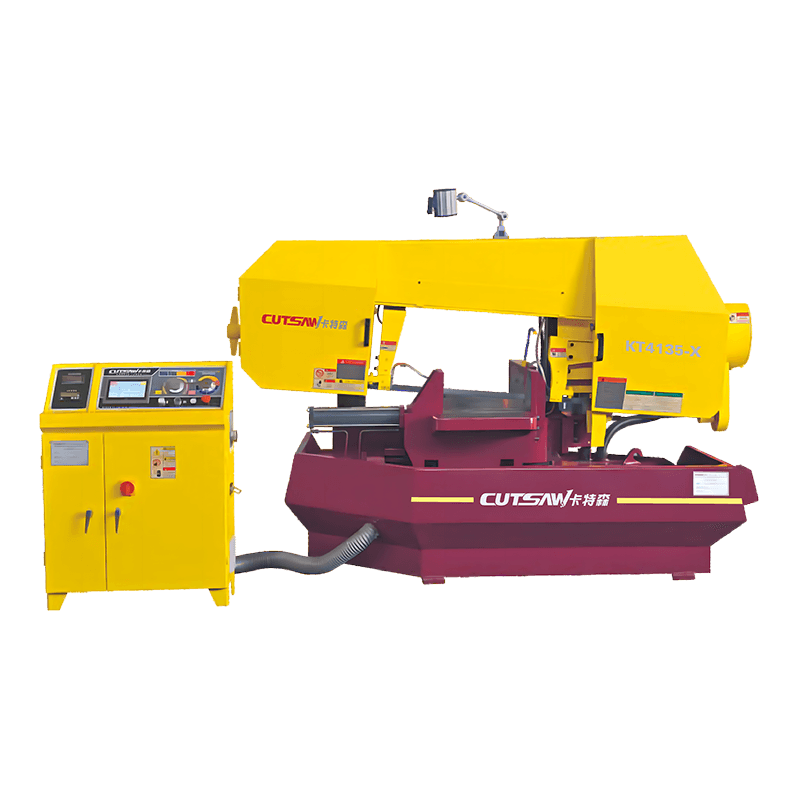

We are a professional CNC band saw machine manufacturer with an annual production capacity of 3,600 units, and we can undertake the design and production of extra-large customized models. Our products are widely used for cutting ferrous and non-ferrous metals, plastics, and other non-metallic materials, and are well received in both domestic and international markets.

The company has passed ISO9001 quality management system certification, China Machinery Safety Certification, and EU CE certification.

Precision CNC Control System — At the core of repeatable performance in a CNC Band Sawing Machine is its computer numerical control (CNC) system. This system ...

READ MORE