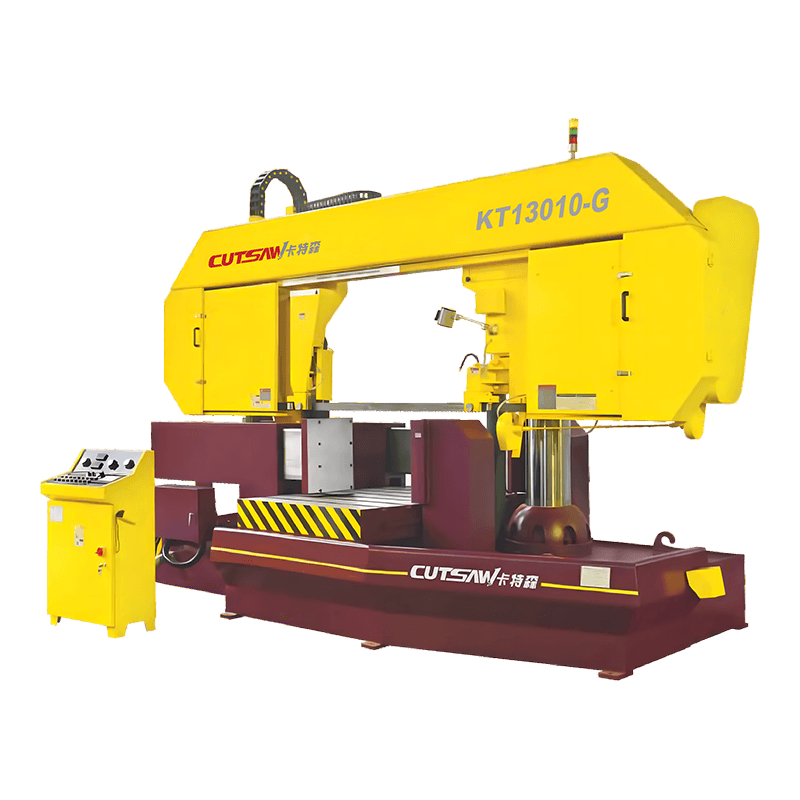

Sturdy Gantry Design for Stability

The gantry-style frame of the Band Sawing Machine is fundamental to ensuring uniform cutting quality. This design provides a robust, stable support system that minimizes vibration and movement during the cutting process. When cutting thicker or irregularly shaped materials, the stability of the gantry structure is crucial for maintaining precision. The frame is designed to absorb the substantial forces generated during cutting, preventing any flexing or shifting that could lead to misalignment. This structural integrity allows the cutting head or the saw blade to remain steady, ensuring that the blade does not veer off course as it cuts through dense or uneven materials. The rigidity of the gantry also ensures that the material being cut does not experience any unwanted movement, allowing for precise and clean cuts with minimal distortion.

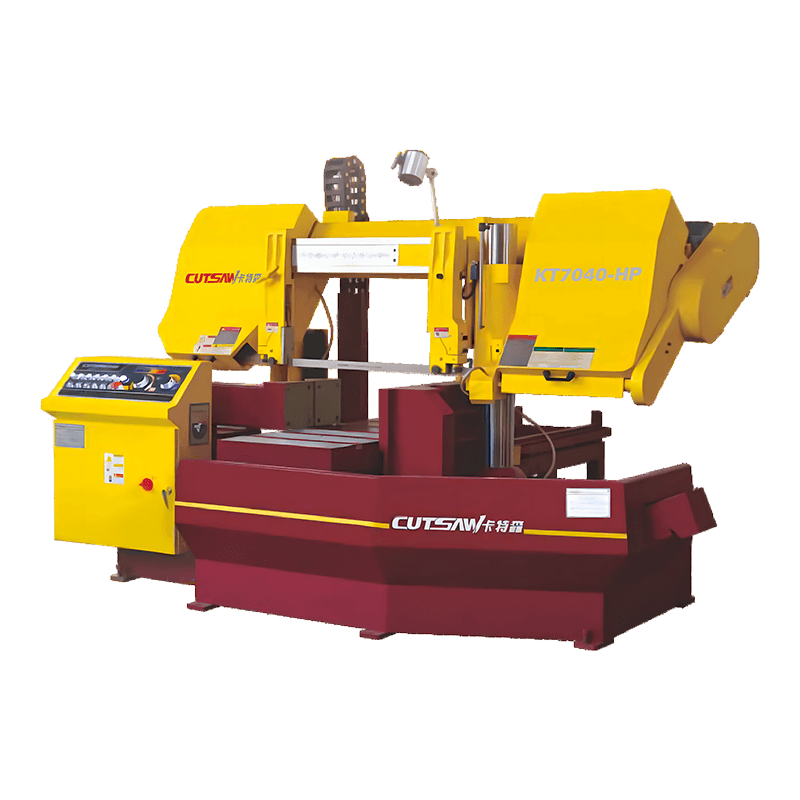

Precision Blade Guidance System

The blade guidance system in the Gantry Band Sawing Machine is specifically engineered to maintain the blade’s stability and precision during operation. These guide systems are typically designed to support the blade at both the top and bottom, preventing lateral movement and ensuring that the blade follows a straight path. High-quality ball bearing guides or tungsten carbide guides are often used in these systems to minimize friction and maintain alignment. This precision is especially critical when cutting thicker materials or when dealing with irregular shapes that might cause the blade to deviate. By keeping the blade aligned throughout the entire cutting process, the guidance system ensures that each cut is uniform, with the blade maintaining its trajectory, regardless of the material's complexity.

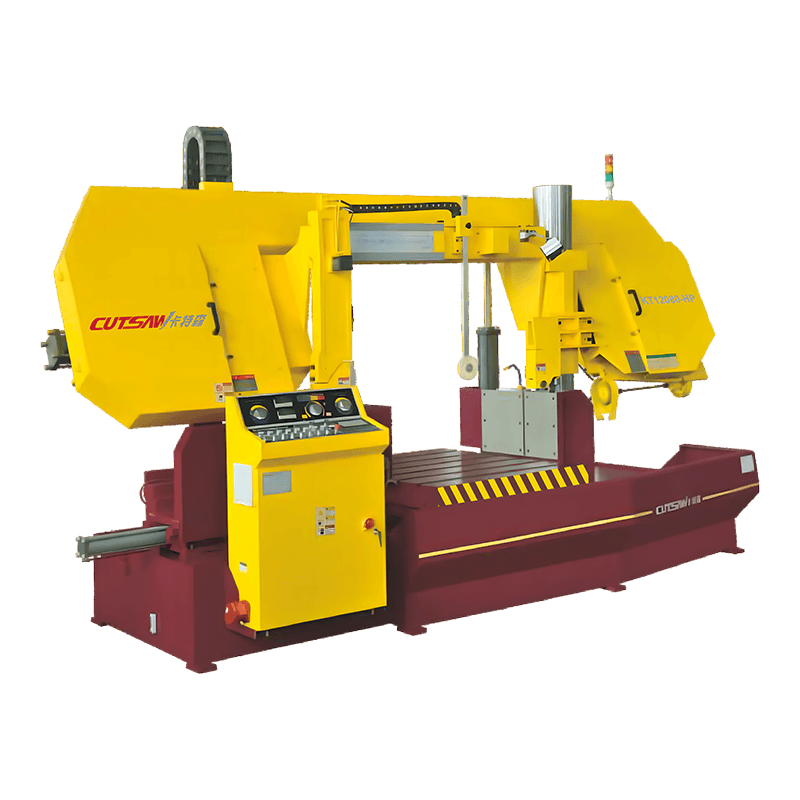

Variable Speed Control

The Gantry Band Sawing Machine's variable speed control feature is an essential component for optimizing cutting performance. This feature allows operators to adjust the speed of the blade depending on the type of material being cut. For instance, when cutting thicker or harder materials, such as steel or metal, a slower cutting speed may be necessary to prevent excessive heat buildup and excessive wear on the blade. Conversely, softer materials can be cut at higher speeds, increasing efficiency. By fine-tuning the cutting speed, operators can optimize the balance between cutting speed and blade longevity, ensuring that cuts are both precise and smooth. The ability to control cutting speed helps prevent issues like material shifting or overheating, which can degrade the cutting quality, especially in irregular or non-uniform materials.

Adjustable Tension on Saw Blade

Blade tension is a critical factor in the performance of any band saw, and it is particularly important when working with large or dense materials. The Gantry Band Sawing Machine features an adjustable blade tension system, which allows operators to set the optimal tension for the blade based on the thickness and hardness of the material being cut. A properly tensioned blade is crucial for achieving consistent, high-quality cuts. Too much tension can lead to blade breakage, while insufficient tension can cause the blade to deflect or wander, resulting in uneven cuts. By maintaining the correct blade tension, the machine ensures that the saw performs consistently throughout the cutting process, maintaining a uniform cutting line, even when cutting challenging or irregularly shaped materials.

Cooling and Lubrication Systems

Cutting materials, especially metals and other dense materials, generates a significant amount of heat, which can cause blade wear, material deformation, and poor cut quality. To combat this, Gantry Band Sawing Machines are typically equipped with sophisticated coolant and lubrication systems that supply a continuous stream of coolant to both the blade and the material being cut. This helps to dissipate heat, reducing the risk of overheating. Additionally, these systems also serve to reduce friction, ensuring that the blade moves smoothly through the material, further enhancing the quality of the cut. In cases where materials are particularly hard or prone to heating up quickly, the coolant can be customized to suit the specific material, ensuring the machine operates efficiently and the material remains stable during cutting. Moreover, the coolant helps extend the life of the blade by preventing excessive wear caused by heat and friction, which is particularly important when working with thick or irregular materials.

Programmable Cutting Parameters

Modern Gantry Band Sawing Machines often come with advanced programmable control systems that allow operators to input specific parameters for different cutting tasks. These parameters can include cutting speeds, feed rates, and blade tension adjustments, all of which are crucial for achieving consistent, high-quality cuts, especially when working with irregularly shaped or complex materials. By programming the machine for specific materials and shapes, operators can ensure that the cutting process is optimized for both precision and efficiency. For example, the machine can be programmed to automatically slow down or adjust feed rates when cutting through areas of higher material density, ensuring that each section of the material is cut with the same level of precision. This is particularly helpful when dealing with non-uniform shapes or materials with varying hardness, as the machine can adjust dynamically to maintain cutting quality across different material types and geometries.

Continuous Monitoring and Adjustments

Many high-end Gantry Band Sawing Machines come equipped with sensors and feedback systems that continuously monitor the performance of the cutting process. These systems track variables such as blade speed, feed rate, material position, and cutting pressure. If any irregularities or fluctuations are detected, the system can automatically adjust the machine's settings in real-time to maintain optimal cutting conditions. This ability to make real-time adjustments is particularly beneficial when cutting thicker materials or irregularly shaped pieces, as it helps the machine adapt to changes in material properties, such as density or surface unevenness. By continuously monitoring the cutting environment, the machine can prevent issues such as blade deflection, excessive wear, or inconsistent cutting quality, ensuring that each cut is as uniform as possible.