-

Continuous Chip Flow via Blade Action:

The design of the band saw blade in a CNC Band Sawing Machine is optimized not only for cutting efficiency but also for efficient chip evacuation. The blade’s tooth geometry, including pitch, rake angle, and tooth set, allows chips to be lifted and ejected from the cutting zone continuously as the blade advances through the material. Proper chip removal reduces the risk of clogging, which can cause overheating, tooth breakage, or deviations in cut quality. This is especially important in high-volume operations where large quantities of chips are generated per cycle. By selecting the appropriate blade type for the material—ranging from mild steel to stainless steel or aluminum—the machine ensures that chip size and ejection are managed to maintain both cutting efficiency and blade longevity. -

Coolant-Assisted Chip Flushing:

CNC Band Sawing Machines in industrial applications typically incorporate integrated coolant or cutting fluid delivery systems. These systems serve the dual purpose of cooling the blade and workpiece while also flushing chips away from the cutting interface. Coolant is delivered directly to the teeth and workpiece contact point through precisely positioned nozzles or internal channels. The flow of coolant washes swarf downward into collection trays, preventing chips from accumulating in the kerf or between teeth. Adjustable coolant flow rates allow operators to optimize chip removal for varying materials, thicknesses, and feed rates, ensuring both efficient operation and high-quality surface finish. Effective coolant-assisted flushing reduces friction, prevents heat buildup, and minimizes the risk of thermal damage to both the blade and workpiece. -

Chip Collection Trays and Reservoirs:

Beneath the cutting area, CNC Band Sawing Machines are equipped with chip collection trays, reservoirs, or hoppers designed to catch swarf that is discharged from the kerf. In high-volume production, these trays are often oversized or supplemented with sloped chutes to guide chips toward collection points efficiently. Properly designed collection systems reduce the likelihood of chips re-entering the blade path, which can damage the workpiece or interfere with blade tracking. By containing swarf in designated areas, operators can also perform easier maintenance and recycling of chips without interrupting production. -

Conveyor and Auger Systems for Continuous Evacuation:

To handle the volume of swarf generated in high-throughput environments, many CNC Band Sawing Machines incorporate mechanical chip transport systems, such as belt conveyors, screw augers, or vibratory feeders. These systems move the collected chips continuously from the base of the machine to bins, storage hoppers, or recycling units. Continuous removal prevents accumulation in the cutting zone, ensuring uninterrupted operation and consistent feed rates. In addition, these automated systems minimize labor requirements, reduce downtime for manual cleaning, and allow production to run efficiently over extended shifts. -

Integration with Coolant Filtration and Recycling Systems:

High-volume cutting operations also benefit from filtered coolant systems, which separate swarf from cutting fluid before it is recirculated. Filtration ensures that chips do not scratch the workpiece, interfere with blade tracking, or cause abrasive wear on machine components. By maintaining a clean coolant supply, the CNC Band Sawing Machine enhances cutting efficiency and blade life while also enabling cost-effective recycling of coolant. This is particularly important in industrial settings where large volumes of cutting fluid are used and sustainability, operational cost reduction, and environmental compliance are priorities.

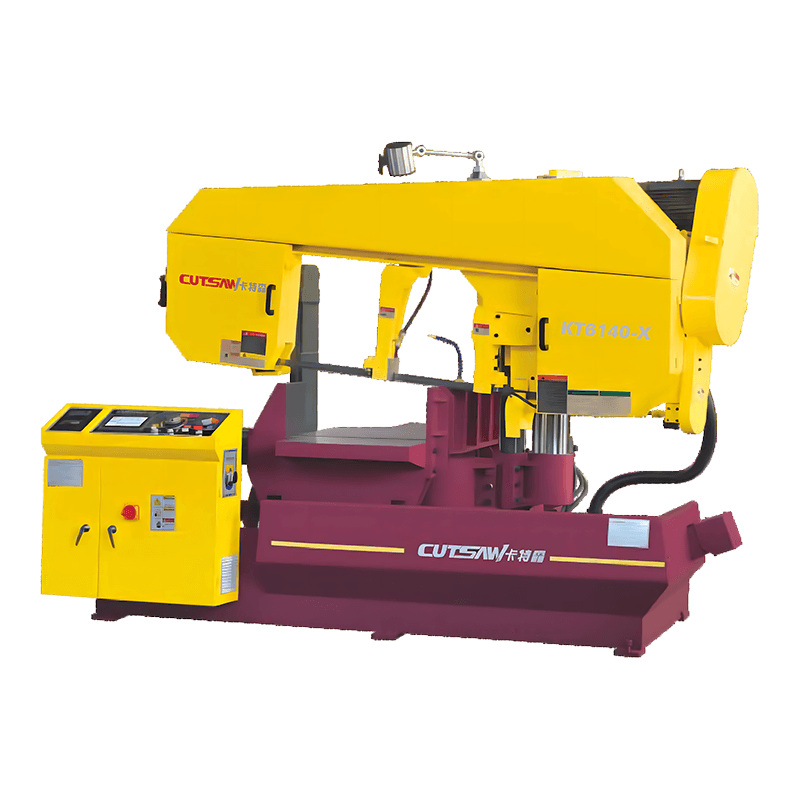

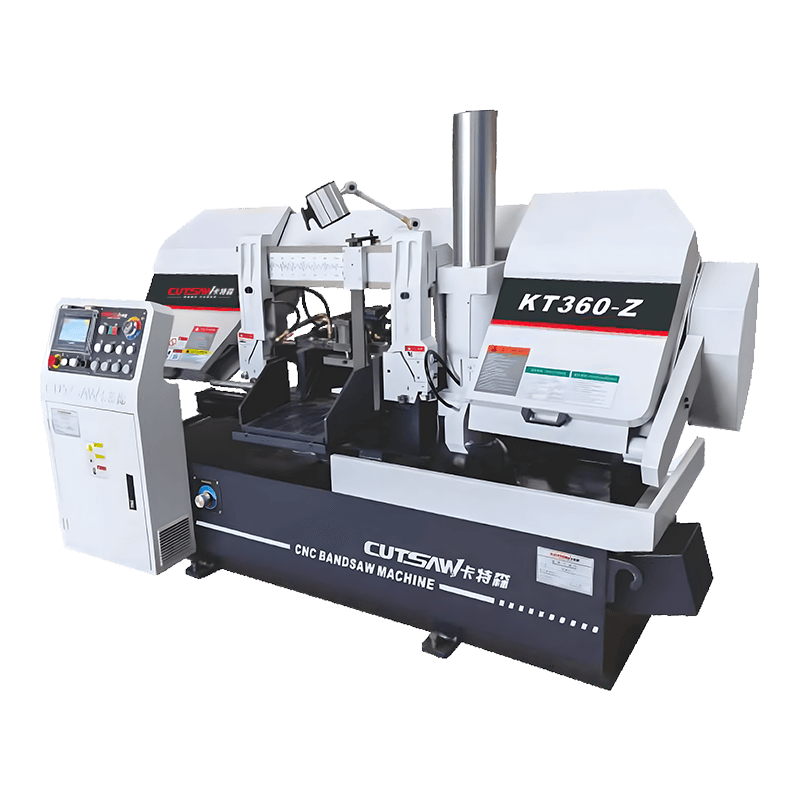

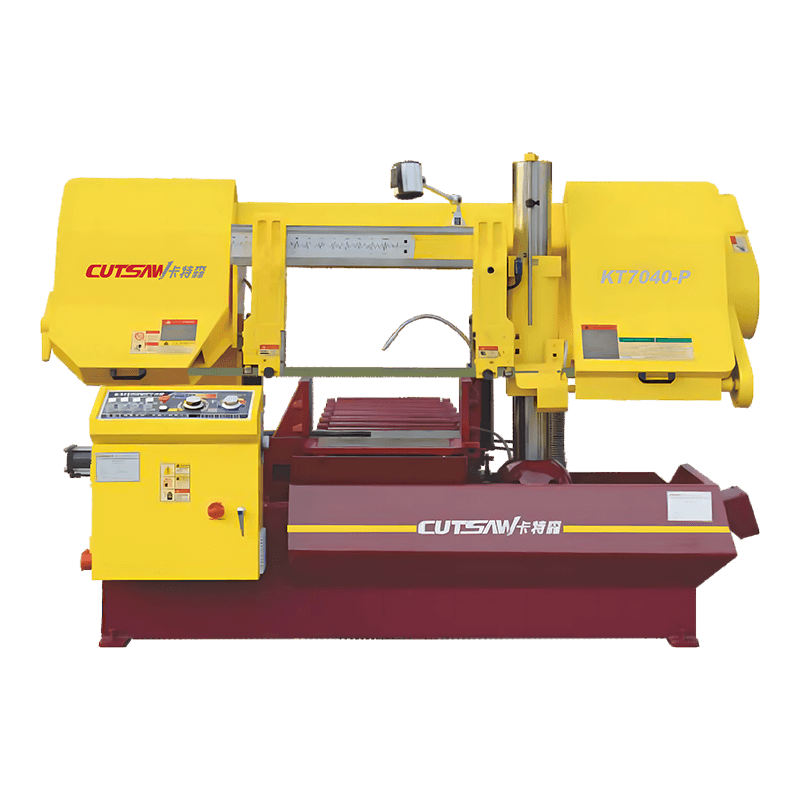

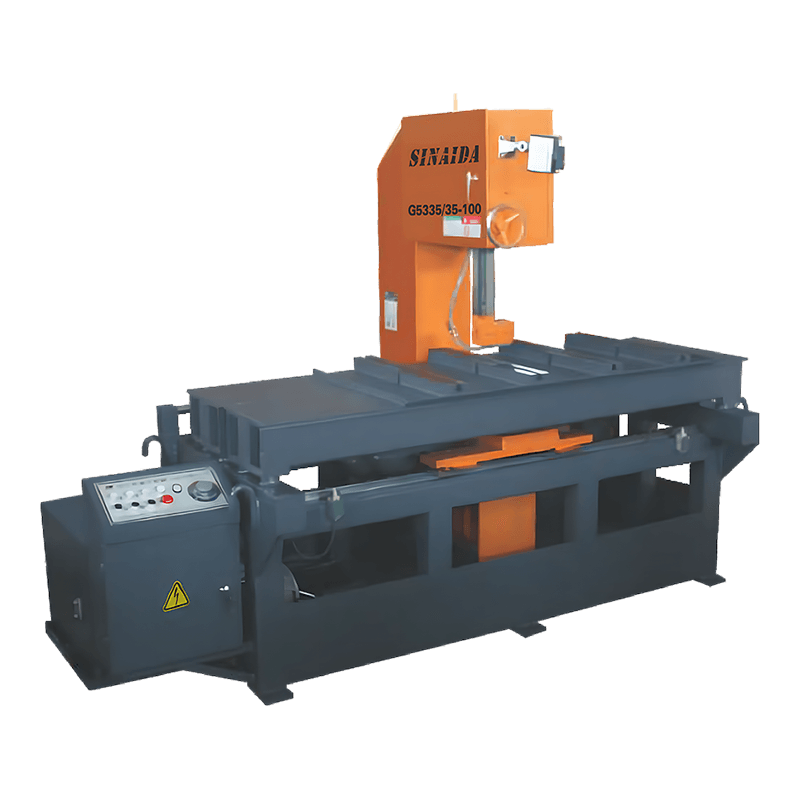

Main features of the machine ● Feeding material adopt dual bilinear guide rail with high precision, low abrasion and long lifetime. ● Work piece feeding adopt transducer step less adjustable , feeding...

See Details