The protective cover of the circular saw machine is divided into two types: tabletop and tablebottom. The countertop lightweight protective cover consists of a support frame, a plexiglass cover, a separation knife and brake pad. During operation, the cover body can swing on the support rack to adapt to changes in wood thickness. There are reinforcement ribs in the cover to increase the vibration resistance of the cover. The sawing of the wood can be clearly seen through the plexiglass cover. This type of protective device is suitable for sawing and cutting sheets with high accuracy requirements, such as laminates, woodworking products, etc. The purpose of the base guard is to prevent operators from being injured by saw blades when cleaning wood chips. Its structure is relatively simple. It is usually protected by steel plates on both sides of the saw blade, and the distance between the two sides is not more than 150mm. Its bottom edge is at least 50mm lower than the sawtooth.

There are six key points for safety protection of woodworking circular saws:

1. The disc saw should be placed smoothly, and a one-way switch must be used and must not be started inverted.

2. If a saw blade has cracks (the length must not exceed 2cm), a crack can be drilled at the end of the crack. When the saw blade has 2 consecutive broken teeth, it must be replaced.

3. There should be a protective cover above the saw blade, and there should be a solitary plate groove at the bottom to prevent wood chips from splashing and saw blade from breaking and injuring people.

4. The saw machine panel should be flat and non-destructive, and the width of the saw blade groove should not be greater than the thickness of the saw blade plus 20mm.

5. The piled wood chips should be cleaned in time, and fireworks should be strictly prohibited at the operation site, and fire-fighting equipment should be equipped as required.

6. Safe use of woodworking machinery

1. Safety of disk saw

After starting, the sawing material can be performed after the speed is normal. When feeding materials, do not shake left and right or lift high. When feeding materials, feed materials slowly. The length of the saw material should be no less than 500mm. When approaching the end, use a push stick to feed the material. Operators shall not operate in the direction of centrifugal force that faces the rotation of the saw blade, and their hands shall not cross the saw blade. When the temperature of the machine sheet is too high, use water to cool.

2. Safety of flat planing

When scattering materials, your hands should be pressed on the material, and your fingers must be more than 50mm away from the scattering port. It is strictly forbidden to use hands to feed materials across the planer at the back end of the wood. Before shaving old materials, the nails and debris on the materials must be cleaned. When encountering wooden rafts and scars, you should deliver the materials slowly. It is strictly forbidden to press your hands on the knuckle and feed the materials. When mechanical operation, do not put your hand into the inner side of the safety baffle to move the baffle or remove the installation baffle for planing. It is strictly forbidden to wear gloves.

3. Safety of use of pressure planer

During operation, it is strictly forbidden to plan two pieces of materials of different materials and specifications at one time, and the thickness of the planed wood shall not exceed 50mm. The operator should stand on one side of the machine tool and should not wear gloves when picking up and delivering materials. The big head must be in front of the feed.

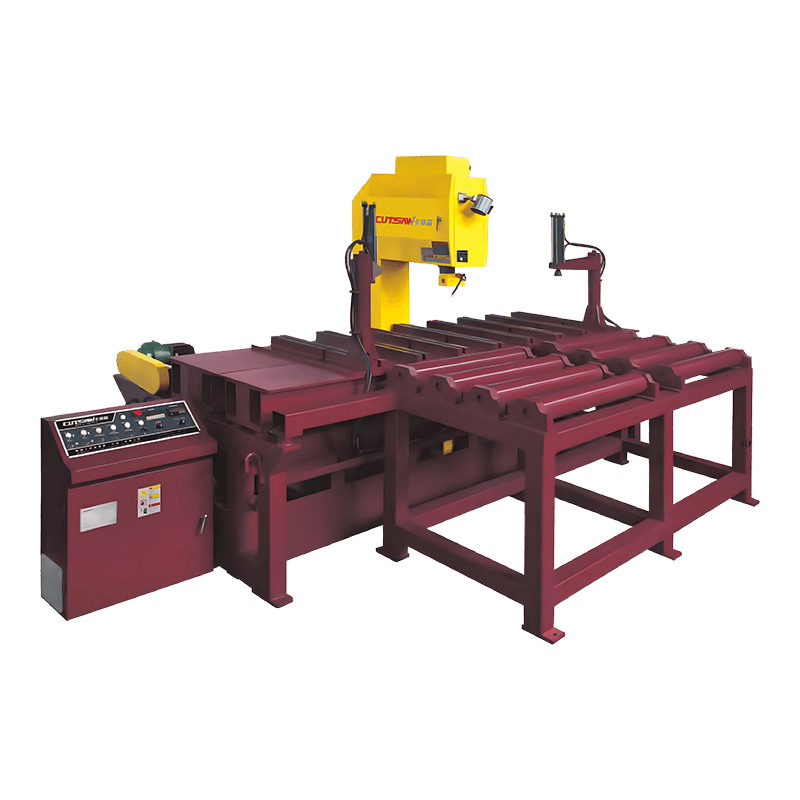

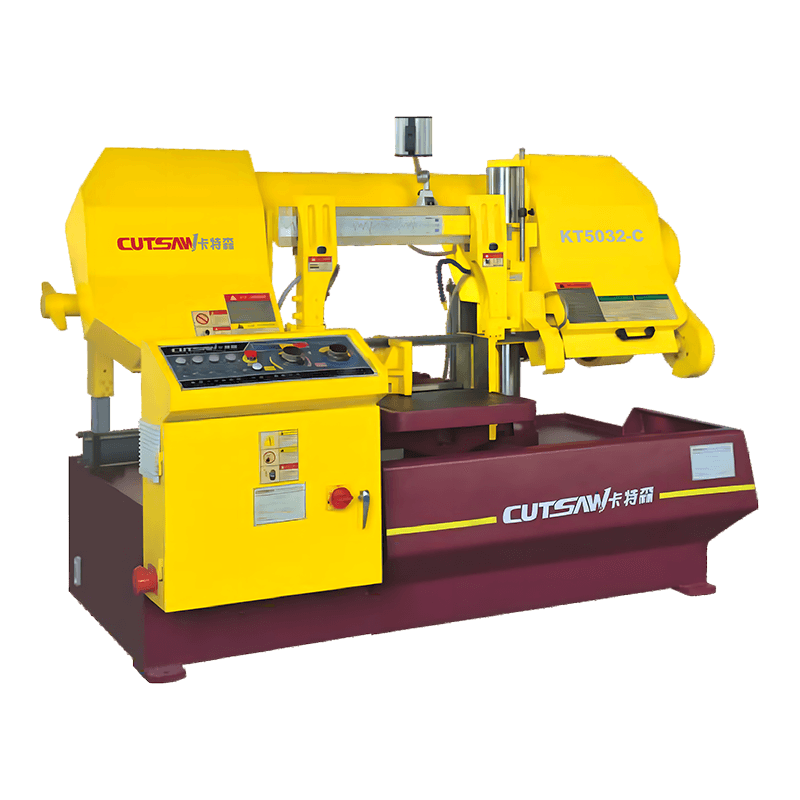

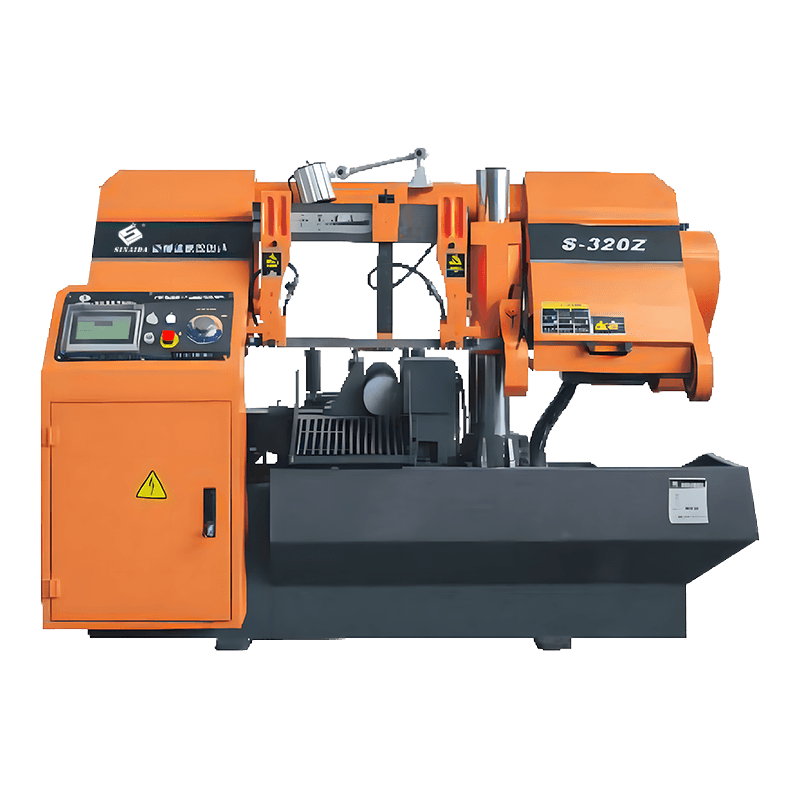

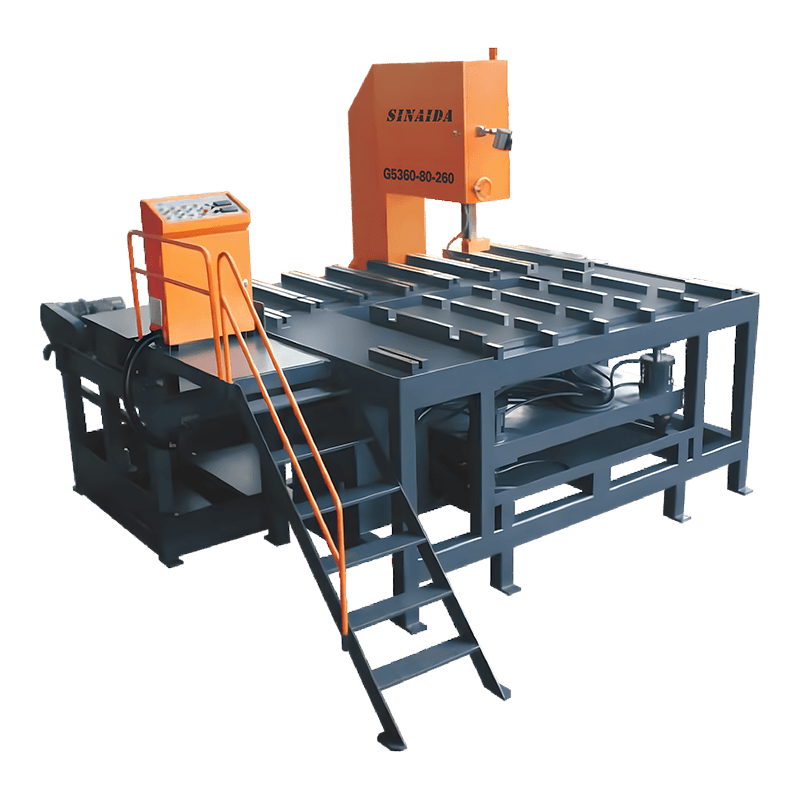

Characteristic description ● Bed mechanism: one cast bed, secondary aging stress relief, high stability, high precision, good seismic performance; ● Wide sawing range, compact design, 35-735 width saw...

See Details