What is an Automatic Band Saw Machine?

An automatic band saw machine is a commonly used cutting tool in industrial manufacturing, primarily for cutting materials like metal, wood, and plastic. It uses a continuous band saw blade to achieve high-speed cutting, and through an automated feeding and control system, it enhances cutting accuracy and production efficiency. Compared to traditional manual band saws, the automatic band saw machine offers a higher level of automation, reducing human intervention, saving labor costs, and improving the quality and efficiency of the products.

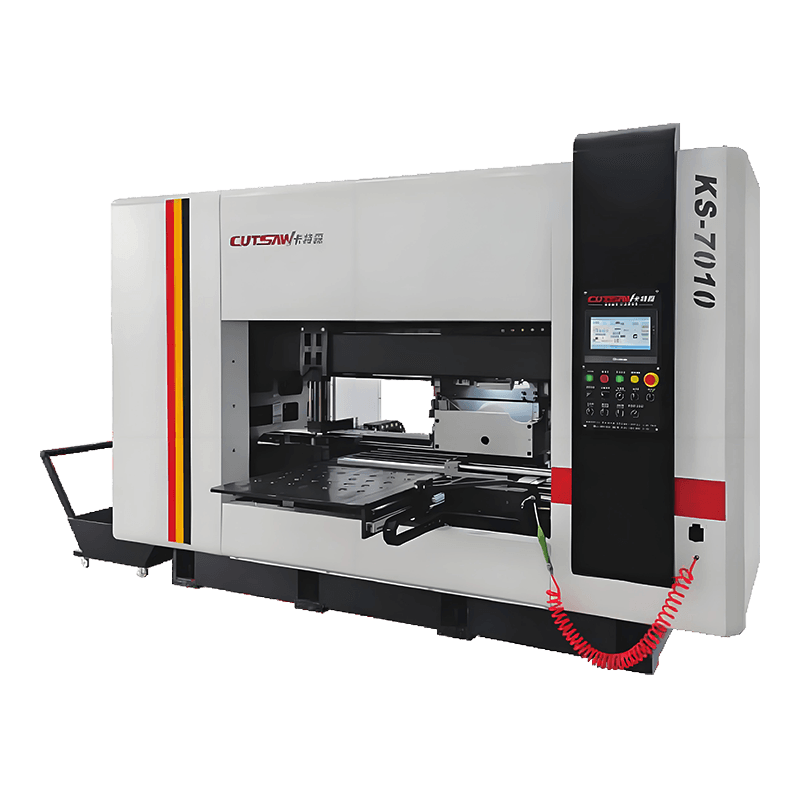

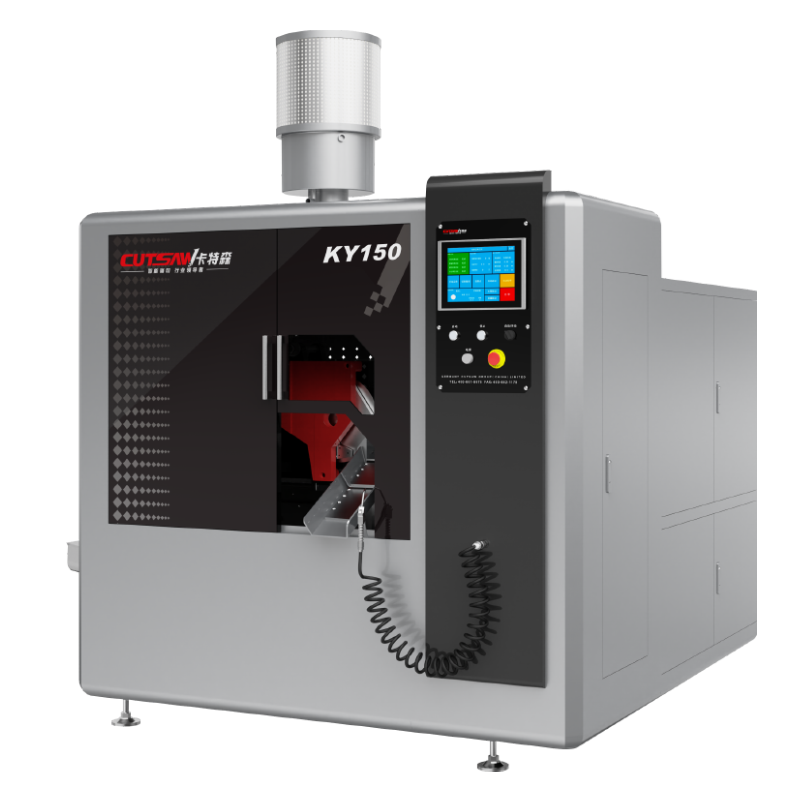

In modern manufacturing, automatic band saw machines are widely used in precision part cutting, batch production, and complex shape processing. They are applicable in various industries such as automotive, aerospace, machinery manufacturing, and construction. As a professional company engaged in the design and production of CNC machines and cutting equipment, Zhejiang Sinaida Machine Tools Co., Ltd. is committed to the development and manufacturing of high-performance automatic band saw machines that help global customers improve production efficiency and processing accuracy.

The automatic band saw machine typically consists of the following key components:

- Band Saw Blade System: The band saw blade is the core part of the cutting operation, and it plays a crucial role in cutting materials accurately. The choice of saw blade significantly affects cutting performance and tool longevity.

- Drive System: The drive system provides the necessary power for the machine, ensuring high-speed operation of the saw blade. Using variable frequency drive technology, the automatic band saw can adjust its speed to optimize cutting for different materials.

- Feeding System: The automatic feeding system allows for precise control of feed speed and pressure. It can automatically adjust based on the cutting process, ensuring smooth and efficient cutting.

- Control System: The automatic band saw machine is typically equipped with a CNC (Computer Numerical Control) system, which precisely controls the cutting path and speed to meet different processing needs. Zhejiang Sinaida Machine Tools Co., Ltd. uses advanced CNC technology in its machines to ensure accurate and stable operations.

The automatic band saw machine not only improves cutting precision but also significantly reduces the operator’s labor intensity, enhancing production efficiency. As a highly efficient industrial tool, it has become an indispensable part of modern production lines.

How Does the Automatic Band Saw Machine Improve Production Efficiency?

The design and functionality of the automatic band saw machine make it an ideal tool for improving production efficiency. Traditional manual cutting methods require more human intervention and are generally less efficient and precise. However, the automatic band saw machine, through its highly automated control system, dramatically increases production efficiency, reduces the impact of human factors on cutting quality, and especially excels in high-volume production and precision processing.

1. Automatic Feeding and Cutting Control

One of the most significant features of the automatic band saw machine is its automatic feeding and cutting control functions. The machine can adjust the feed speed and pressure during the cutting process, adapting to different materials. This automation not only reduces the need for manual adjustments but also ensures uniformity and accuracy in each cut, preventing fluctuations in quality due to human error.

For example, the automatic band saw machines offered by Zhejiang Sinaida Machine Tools Co., Ltd. are equipped with advanced servo motors and sensor systems that dynamically adjust the feed speed based on material hardness and cutting conditions, ensuring optimal cutting results. This not only enhances production efficiency but also extends the life of the saw blade, reducing downtime caused by tool wear.

2. Precise Cutting Path Control

The automatic band saw machine uses CNC (Computer Numerical Control) technology to control the cutting path, allowing for high-precision cutting. The CNC system can automatically generate cutting paths based on design drawings and adjust cutting parameters in real-time to meet different production requirements. This precise control significantly reduces errors in the cutting process, improving the consistency and accuracy of the final product. The automatic band saw machine is especially effective in complex shapes and high-volume production, where consistent quality is essential.

3. Improved Material Utilization

The automatic band saw machine also optimizes the cutting process, maximizing material usage and minimizing waste. In manual operations, human factors often limit the cutting accuracy and material utilization. However, the CNC system in an automatic band saw machine calculates the optimal cutting plan, minimizing scrap and increasing the efficiency of material use. By optimizing cutting paths, companies can save a significant amount of raw material costs during production.

4. Efficient Production and Versatile Applications

The automatic band saw machines from Zhejiang Sinaida Machine Tools Co., Ltd. are designed to cut a variety of materials, including metal, plastic, and wood. By changing the saw blade and adjusting parameters, the machine can adapt to different processing needs. Whether it is high-volume standard cutting or custom cutting for complex shapes and small batches, the automatic band saw machine offers highly efficient solutions, greatly enhancing production efficiency.

Production Efficiency Comparison

| Advantage |

Traditional Manual Saw |

Automatic Band Saw Machine |

| Cutting Precision |

Low, affected by human factors |

High precision, automatic adjustment of cutting parameters |

| Production Efficiency |

Low, requires frequent human intervention |

High efficiency, reduces manual involvement |

| Material Utilization |

Low, cutting plan not optimized |

High, optimized cutting paths and material layout |

| Ease of Operation |

High, relies on operator experience |

Low, automated control, easy to use |

| Material Variety |

Limited adaptability |

High, can cut a wide range of materials and shapes |

What Are the Maintenance and Safety Measures for Automatic Band Saw Machines?

Automatic band saw machines are high-precision and high-efficiency industrial equipment, but regular maintenance and upkeep are essential to ensure long-term stable operation and improve safety. Zhejiang Sinaida Machine Tools Co., Ltd. takes maintenance and ease of service into account when designing its automatic band saw machines, ensuring that customers can extend the equipment’s lifespan while ensuring smooth operation.

1. Regular Inspection and Replacement of Saw Blades

The saw blade is one of the most important components of the automatic band saw machine, and regular inspection and replacement are essential to maintaining cutting accuracy and efficiency. The condition of the saw blade directly affects cutting performance, so once significant wear or cracks are noticed, it should be replaced promptly. Additionally, selecting the appropriate saw blade material and specifications can greatly extend its lifespan.

2. Cleaning and Lubricating the Equipment

Automatic band saw machines need to be regularly cleaned and lubricated, especially key components such as the feeding system, drive system, and control system. Regular cleaning helps remove chips, dust, and other debris from the machine, preventing wear on internal parts. Lubrication ensures smooth operation of mechanical components, reducing friction and heat buildup, which in turn enhances the longevity of the equipment.

3. Regular Inspection of the Electrical Control System

The electrical control system is the “brain” of the automatic band saw machine, responsible for controlling various machine functions. Regular checks and maintenance of the electrical control system are essential to ensure that electrical components are not loose, damaged, or aging. Zhejiang Sinaida Machine Tools Co., Ltd.’s automatic band saw machines are equipped with high-quality electrical control systems that feature real-time fault diagnostics, helping operators quickly address issues when they arise.

4. Safety Operating Procedures

To ensure operator safety, automatic band saw machines are typically equipped with several safety features, such as emergency stop buttons, automatic shutdown devices, and protective covers. Operators should adhere to safety protocols, wear appropriate protective gear (such as safety glasses, earplugs, gloves, etc.), and regularly undergo safety training. Maintenance personnel should also create a regular inspection schedule based on machine usage and environmental conditions to prevent accidents caused by equipment failure.

Through proper maintenance and safety measures, automatic band saw machines can provide long-term, stable benefits, increasing production efficiency while ensuring worker safety. Zhejiang Sinaida Machine Tools Co., Ltd. is dedicated to providing customers with high-quality, high-performance automatic band saw machines, as well as comprehensive after-sales service and technical support to help clients achieve sustainable production benefits.